Cathode diffusion layer for proton exchange membrane fuel cell, preparation and application thereof

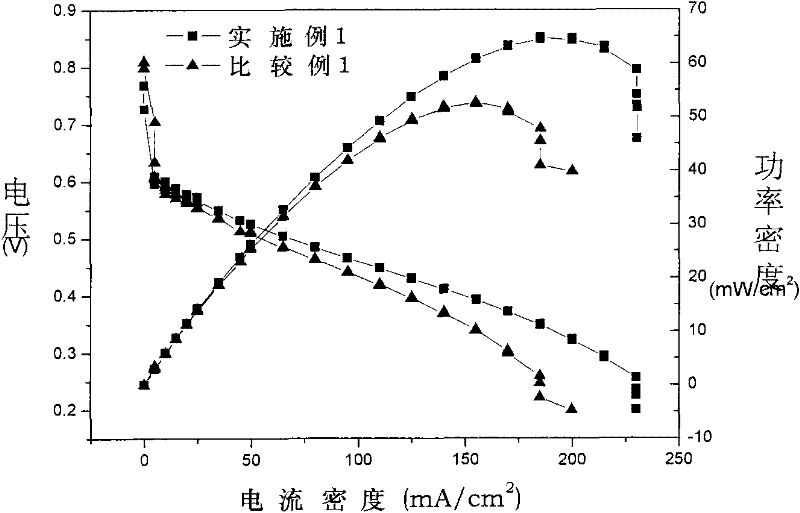

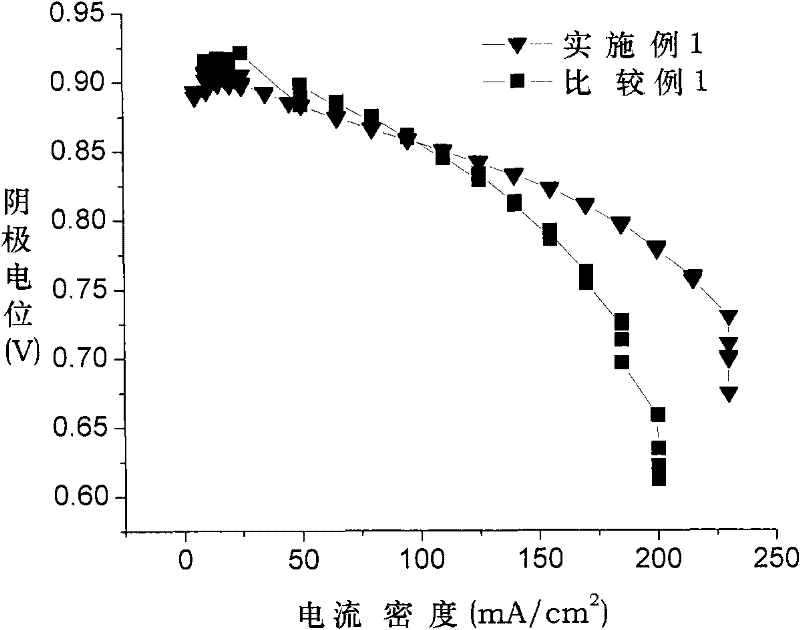

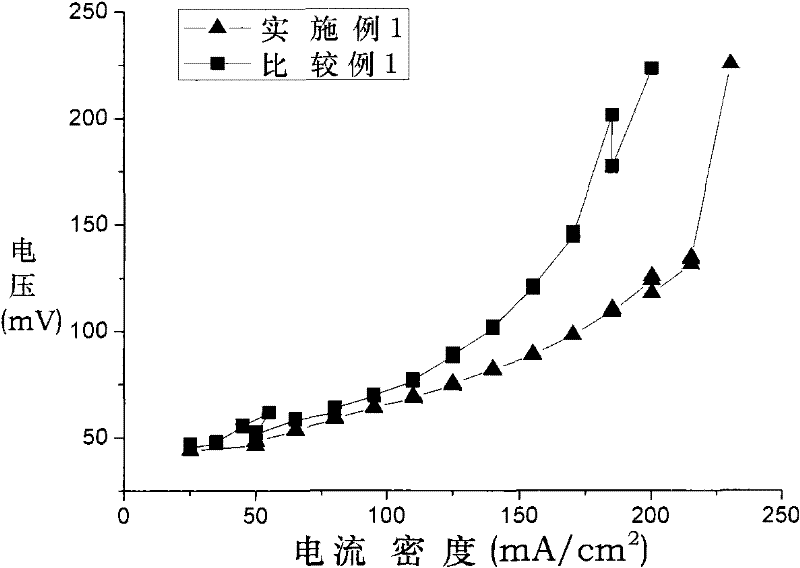

A technology of proton exchange membrane and fuel cell, applied in the field of diffusion layer, can solve the problems of mass transfer obstruction of cathode material, achieve the effect of improving mass transfer capacity, improving battery performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of support layer: Use a gas spray gun to evenly spray PTFE water dispersion with a mass concentration of 1-2% on one side of the carbon paper or carbon cloth. During the spraying process, after spraying a layer of PTFE water dispersion, use a hot air blower to Blow dry, and then continue to spray the next layer until it is loaded with carbon paper or carbon cloth with 10-20wt.% PTFE, and then place it in a muffle furnace for heat treatment at 320-360°C for 1-1.5 h, obtain carbon paper or carbon cloth treated with one-sided hydrophobic treatment, which can be used as a support layer for the diffusion layer;

[0034]Slurry preparation of the microporous layer: carbon powder mass 5wt.% oxygen storage material Gd 0.1 Ce 0.9 o 2 After the powder is mixed with carbon powder, it is dispersed in absolute ethanol with 55 times the mass of carbon powder to form a slurry, which is ultrasonically oscillated for 10 minutes and then 10 wt. Minutes to disperse PTFE even...

Embodiment 2

[0044] The preparation process of the support layer is the same as in Example 1.

[0045] Slurry preparation of the microporous layer: Mix carbon powder mass 5wt.% oxygen storage material CeO2 powder with carbon powder, disperse in 55 times the mass of carbon powder in absolute ethanol to form a slurry, and add 15 The 10wt.% concentration of PTFE water dispersion that is twice the mass of carbon powder, and mechanically stirred for 10 minutes to disperse the PTFE in the slurry evenly.

[0046] Preparation of the diffusion layer: uniformly prepare the microporous layer slurry onto the side of the carbon paper or carbon cloth sprayed with PTFE in the above step (a) by scraping coating. During the scraping process, after each layer of slurry is loaded, The solvent needs to be evaporated before the next layer of loading is carried out, and the above steps are repeated until the carbon powder loading is 2mg / cm 2 , the cathode diffusion layer was prepared after heat treatment at 34...

Embodiment 3

[0050] The preparation process of the support layer is the same as in Example 1.

[0051] Slurry preparation of the microporous layer: carbon powder quality 8wt.% oxygen storage material Ce 0.1 Zr 0.9 o 2 After the powder is mixed with carbon powder, it is dispersed in absolute ethanol with 50 times the mass of carbon powder to form a slurry, which is ultrasonically oscillated for 15 minutes and then added with a PTFE aqueous dispersion of 6 times the mass of carbon powder at a concentration of 5 wt.%. Minutes to disperse PTFE evenly in the slurry.

[0052] Preparation of the diffusion layer: uniformly prepare the microporous layer slurry onto the side of the carbon paper or carbon cloth sprayed with PTFE in the above step (a) by scraping coating. During the scraping process, after each layer of slurry is loaded, The solvent needs to be evaporated before the next layer of loading is carried out, and the above steps are repeated until the carbon powder loading is 1.5mg / cm 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com