Lithium metal composite electrode, preparation method thereof and lithium ion battery

A lithium-ion battery, composite electrode technology, applied in electrode manufacturing, electrode carrier/current collector, negative electrode, etc., can solve the problems of short circuit, easy generation of lithium dendrite volume, swelling battery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

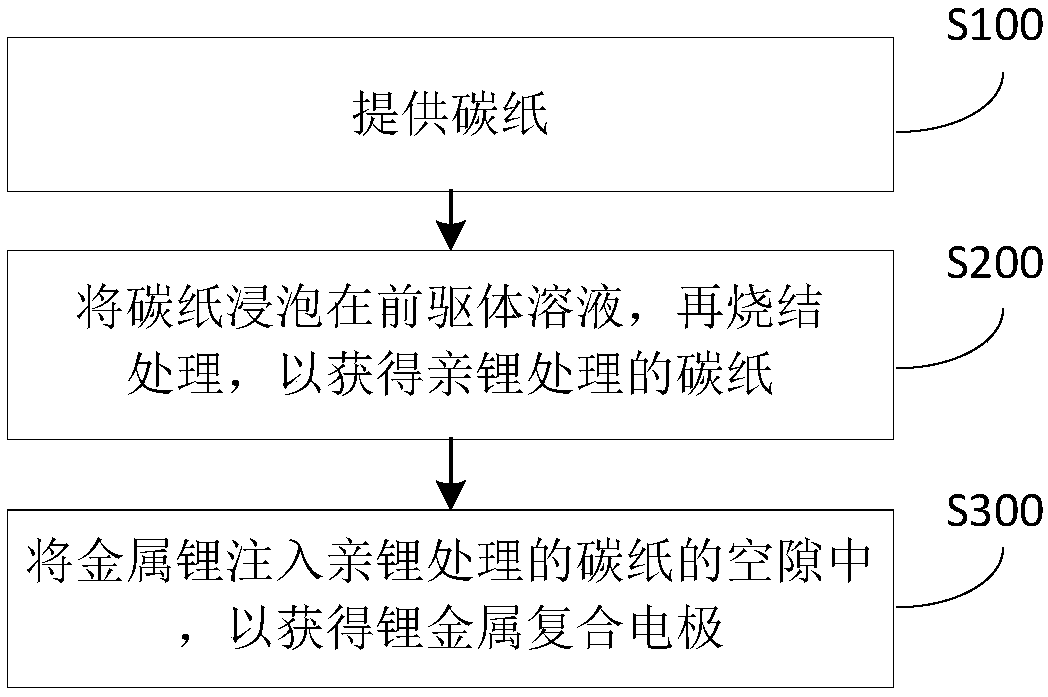

[0060] According to an embodiment of the present invention, refer to figure 2 , the preparation method comprises:

[0061] S100: Provide carbon paper.

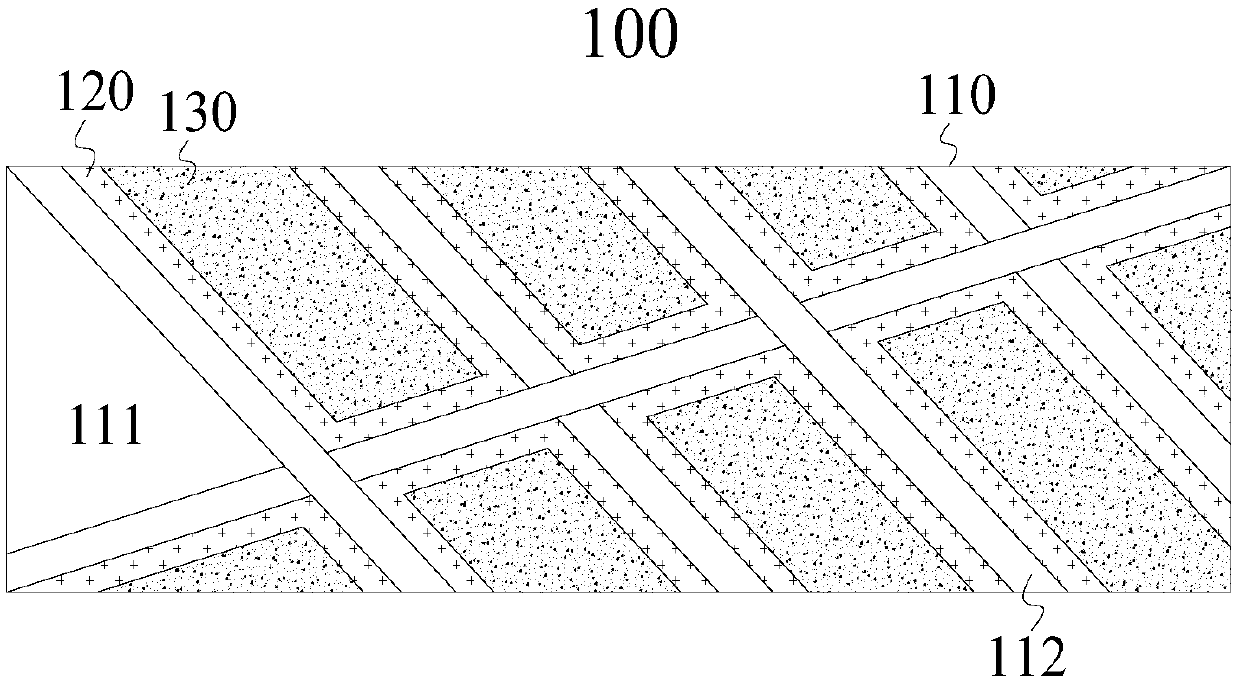

[0062] In this step, a carbon paper 110 having a three-dimensional structure is provided as a porous supporting structure of the lithium metal composite electrode 100 . According to the embodiment of the present invention, the method of providing carbon paper 110 is not particularly limited and can be purchased directly, and carbon fibers can also be formed by methods such as molding. Those skilled in the art can choose to provide carbon paper 110 according to the specific size of the lithium metal composite electrode. way, which will not be repeated here.

[0063] S200: soaking the carbon paper in the precursor solution, and then sintering the carbon paper to obtain the lithium-friendly carbon paper.

[0064] In this step, soak the carbon paper in step S100 in the zinc-containing organic solution to fully wet it, and then...

Embodiment 1

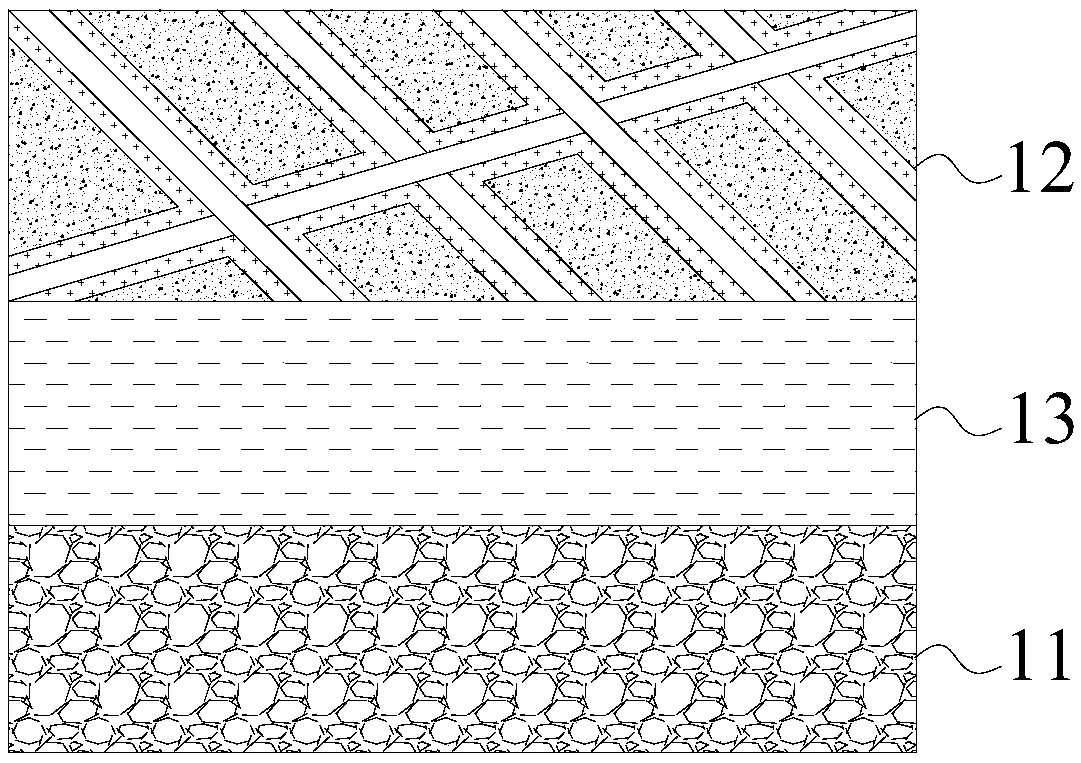

[0076] In this example, a lithium metal composite negative electrode was prepared. The specific steps are as follows:

[0077] (1) Preparation of zinc-containing organic solution (Zn-sol): Zinc acetate dihydrate, ethanolamine and n-propanol are used as raw materials, magnetically stirred and heated and dissolved at 40-60°C to obtain clear, transparent and uniform Zn-sol solution;

[0078] (2) Lithophilic treatment of carbon paper: Soak carbon paper (thickness 150 microns, carbon fiber diameter 5-8 microns, porosity 70-75%) in Zn-sol solution, transfer to drum In an air drying oven, dry at 100-120°C for 5-30 minutes to remove excess solvent, then move the carbon paper to a muffle furnace and raise the temperature to 510-550°C at a rate of 5-10°C / min Sintering at high temperature for 10 to 30 minutes to obtain carbon paper with a lithium-friendly surface;

[0079] (3) Heat the lithium sheet in a nickel vessel or a stainless steel vessel to 240-400°C. After the lithium sheet is ...

Embodiment 2

[0084] In this example, the lithium metal composite negative electrode prepared in Example 1 is used to form a Li-CP / / Li-CP symmetric battery, and its liquid electrolyte uses aluminum hexafluorophosphate, and the area current density is 3mA / cm 2 , The area specific capacity is 1mAh / cm 2 Under the conditions of the cycle charge and discharge test.

[0085] The cycle stability test result of the symmetrical battery of this embodiment is as follows Figure 7 As shown, among them, Figure 7 The abscissa of is time (Time, unit is s), and the ordinate is overpotential (Overpotential, unit is V). from Figure 7 It can be seen that the overvoltage in the first 50 cycles is stably maintained below 0.2V, and the overvoltage gradually increases to 0.4V in the 100th cycle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com