Silicon-carbon negative electrode material for lithium ion battery and lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of poor stability and insignificant volume expansion of silicon-based negative electrode materials, and achieve good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

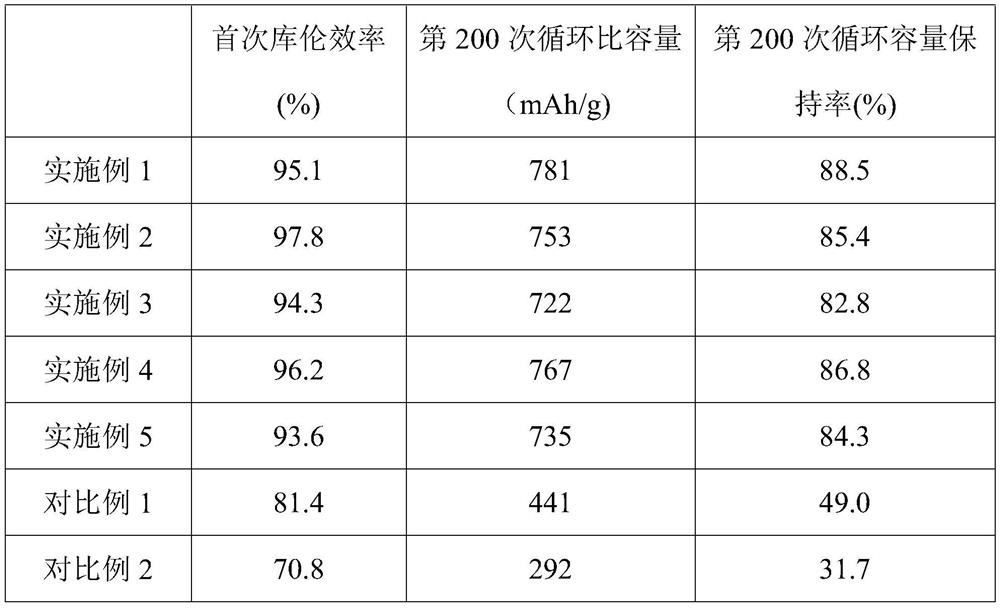

Embodiment 1

[0025] A silicon-carbon negative electrode material for a lithium-ion battery, the preparation method comprising:

[0026] (1), 1g of nano silicon powder (average particle size 100nm) was added to 10mL of hydrofluoric acid solution (10wt%) and stirred for 10min, centrifuged to obtain a solid, washed 3 times with water, then dried at 80°C for 2h, then Insulate the dried silicon powder at 500°C for 10 minutes to obtain surface hydroxylated silicon powder;

[0027] (2), under nitrogen protection, add 2.16g 3,3'-dihydroxybenzidine and 4.00g 4,4'-diaminodiphenyl ether into 60mL anhydrous N,N-dimethylacetamide and stir evenly , then add 8.83g 3,3',4,4'-biphenyltetracarboxylic dianhydride, stir and react at room temperature for 5h to obtain a polyamic acid solution, add 1.8mL pyridine to the polyamic acid solution as imide Add 5 mL of acetic anhydride as a dehydrating agent after the dispersion is complete, heat up to 80°C, stir and react for 4 hours, and cool to room temperature to...

Embodiment 2

[0030] A silicon-carbon negative electrode material for a lithium-ion battery, the preparation method comprising:

[0031] (1), 1g of nano silicon powder (average particle size 100nm) was added to 10mL of hydrofluoric acid solution (10wt%) and stirred for 10min, centrifuged to obtain a solid, washed 3 times with water, then dried at 80°C for 2h, then Insulate the dried silicon powder at 500°C for 20 minutes to obtain surface hydroxylated silicon powder;

[0032] (2), under nitrogen protection, add 2.16g 3,3'-dihydroxybenzidine and 4.00g 4,4'-diaminodiphenyl ether into 60mL anhydrous N,N-dimethylacetamide and stir evenly , then add 6.73g 1,2,4,5-cyclohexanetetracarboxylic dianhydride, stir and react at room temperature for 5h to obtain a polyamic acid solution, add 1.8mL pyridine to the polyamic acid solution as an imidization agent After the dispersion is complete, add 5 mL of acetic anhydride as a dehydrating agent, heat up to 80°C, stir and react for 4 hours, and cool to ro...

Embodiment 3

[0035] A silicon-carbon negative electrode material for a lithium-ion battery, the preparation method comprising:

[0036] (1), 1g of nano-silica powder (average particle diameter 100nm) is added in 10mL sodium hydroxide aqueous solution (10wt%), after heating up to 50 DEG C, stir and react for 30min, centrifuge to obtain the solid, wash 3 times with water, and then wash at 80 Dry at ℃ for 2 hours, and then heat the dried silicon powder at 600℃ for 5 minutes to obtain surface hydroxylated silicon powder;

[0037] (2), under nitrogen protection, add 2.16g 3,3'-dihydroxybenzidine and 4.33g 4,4'-diaminodiphenylsulfide into 60mL of anhydrous N,N-dimethylacetamide and stir Evenly, add 8.83g 3,3',4,4'-biphenyltetracarboxylic dianhydride, stir and react at room temperature for 5h to obtain a polyamic acid solution, add 1.8mL pyridine to the polyamic acid solution as an imide Add 5 mL of acetic anhydride as a dehydrating agent after the dispersion is complete, heat up to 80°C, stir f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com