A three-dimensional porous lithium negative electrode protected by a surface organic modification layer and its preparation method and application

A three-dimensional porous and modified layer technology, which is applied in the direction of negative electrodes, battery electrodes, lithium batteries, etc., can solve the problems of high energy density advantages of engulfing metal lithium, lower energy density of negative electrodes, uneven distribution of lithium deposition, etc., to achieve suppression of unevenness Effects of deposition, suppression of dendrites, and reduction of average current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

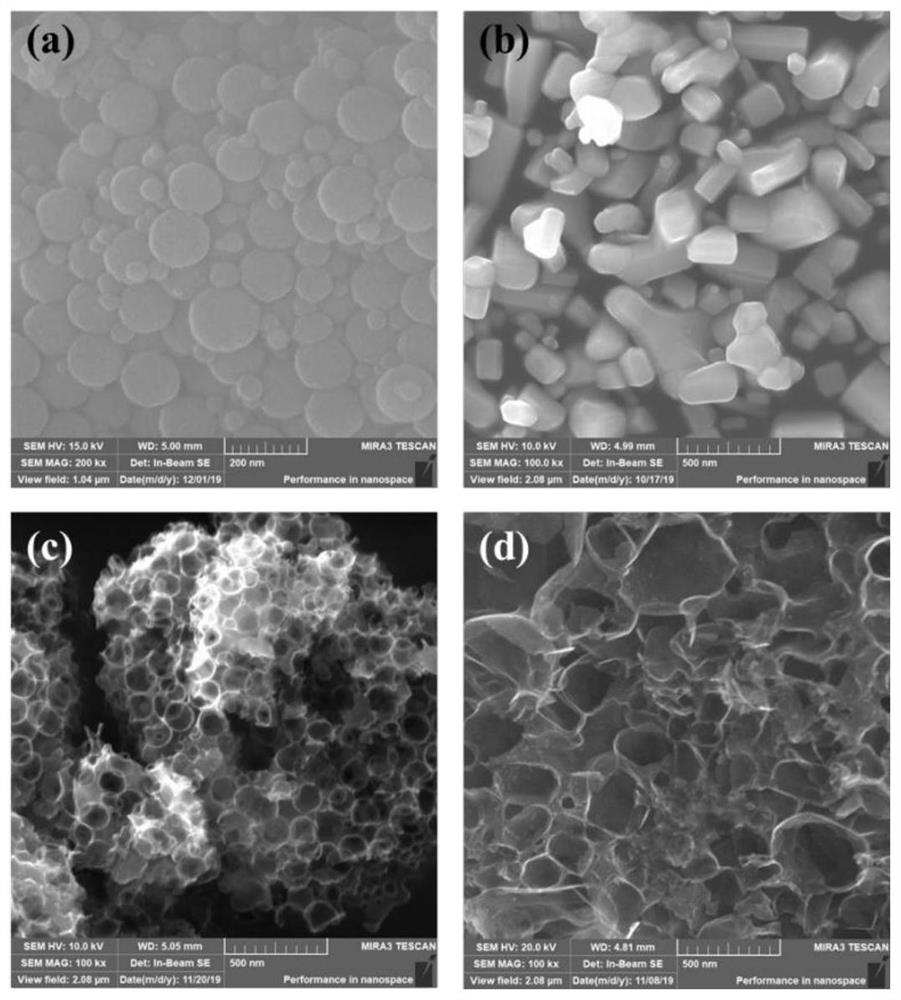

[0034] (1) SiO with a diameter of 150nm 2 The sphere was used as a template, cassava flour was used as organic carbon, uniformly mixed according to the mass ratio of template to organic carbon of 1:6, carbonized in a tube furnace at 1000 °C for 3 hours, and then the template was cleaned with NaOH with a concentration of 3M / L to obtain the required The porous carbon (the specific surface area is 957m 2 / g; the particle size is 180nm; the pore diameter of the internal communicating pores is 150nm~200nm).

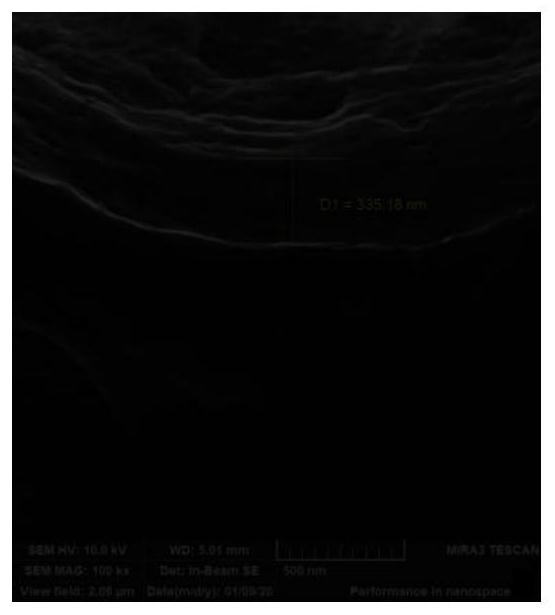

[0035](2) Porous carbon, ferrocene gel (viscosity: 25mPa s; molecular weight: 10000) and PVDF are evenly dispersed in NMP according to the mass ratio of 9:0.5:0.5 to form a uniform slurry, which is coated on the copper foil set On the fluid, the coating thickness is 30μm, and after vacuum drying, the amount of electrodeposited lithium in the coin cell is 5mAh / cm 2 , the three-dimensional porous lithium negative electrode protected by the surface modification layer (thickness...

Embodiment 2

[0049] (1) Fe with a diameter of 350nm 2 o 3 The sphere was used as a template, and glucose was used as organic carbon. According to the mass ratio of template and organic carbon of 1:5, it was uniformly mixed, carbonized in a tube furnace at 1100 °C for 4 hours, and then the template was cleaned with HCl with a concentration of 3M / L to obtain the required The porous carbon (specific surface area is 1083m 2 / g; the particle size is 400nm; the pore diameter of the internal communicating pores is 350nm~400nm).

[0050] (2) Porous carbon, carboxylic acid groups and o-xylene generate gel (viscosity: 30mPa s; molecular weight: 12000) and PVDF are uniformly dispersed in NMP according to the mass ratio of 9:0.5:0.5 to form a uniform slurry, Coated artificial SEI film with a thickness of 150nm, coated on the copper foil current collector with a coating thickness of 30μm, after vacuum drying, the amount of electrodeposited lithium in the button battery is 5mAh / cm 2 , the three-dimen...

Embodiment 3

[0064] (1) Fe with a diameter of 500nm 2 o 3 The sphere is used as template, glucose is used as organic carbon, uniformly mixed according to the mass ratio of template and organic carbon of 1:4, carbonized in a tube furnace at 1200°C, and then the template is cleaned with HCl with a concentration of 3M / L to obtain the desired porous Carbon (specific surface area is 1187m 2 / g; the particle size is 550nm; the pore diameter of the internal communicating pores is 500nm~600nm).

[0065](2) Porous carbon and porphyrin derivatives form gels in ZnP3-cyclohexane (viscosity: 35mPa s; molecular weight: 13000) and PVDF are uniformly dispersed in NMP according to the mass ratio of 9:0.5:0.5 to form Uniform slurry, coated on the copper foil current collector, the coating thickness is 30μm, after vacuum drying, the amount of electrodeposited lithium in the button battery is 5mAh / cm 2 , the three-dimensional porous lithium negative electrode protected by the surface modification layer (th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com