A preparation method of carbon nanosheet material and its application in sodium ion battery

A carbon nanosheet, carbon source technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor performance cycle stability, mismatched interlayer spacing, weak sodium storage ability, etc., to achieve good wettability and cheap raw materials. , the effect of moderate layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

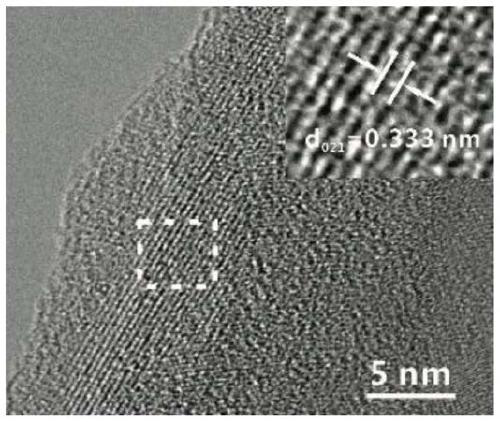

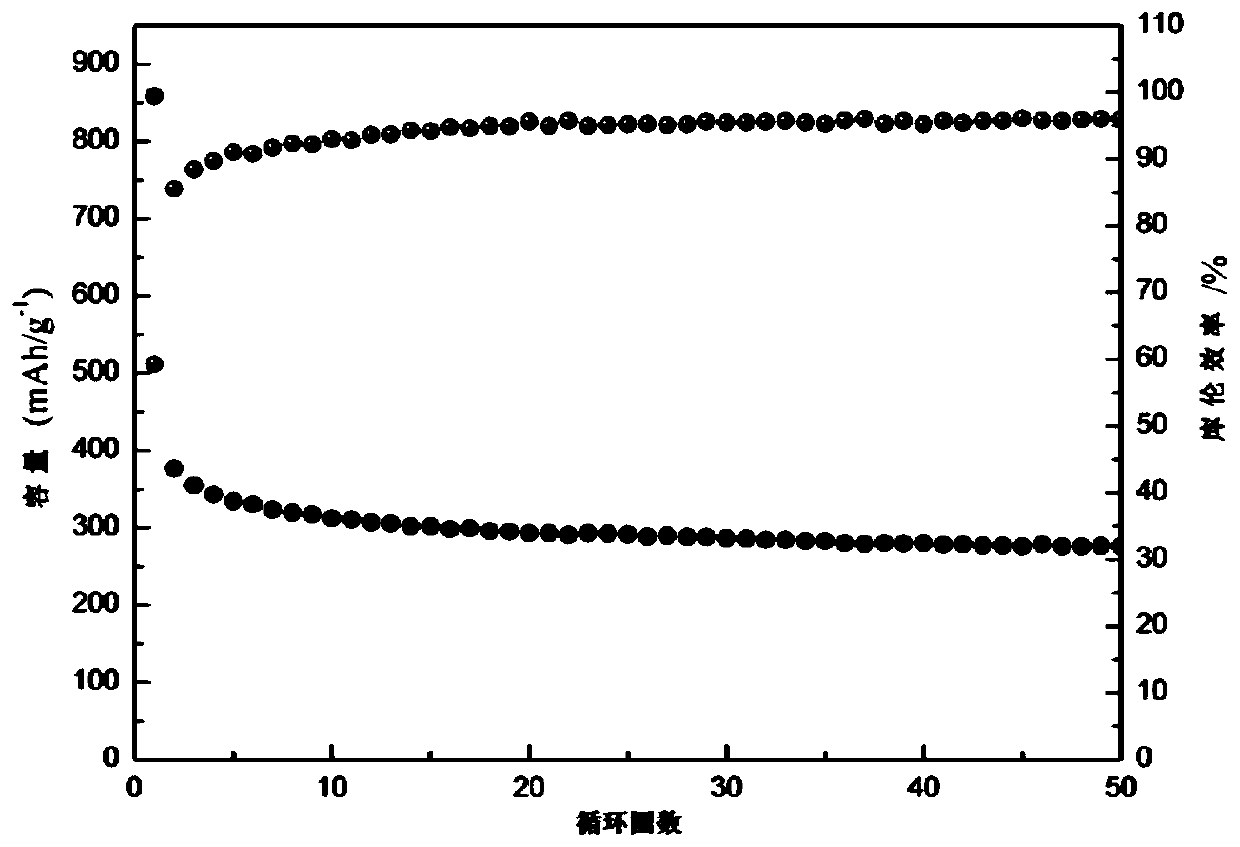

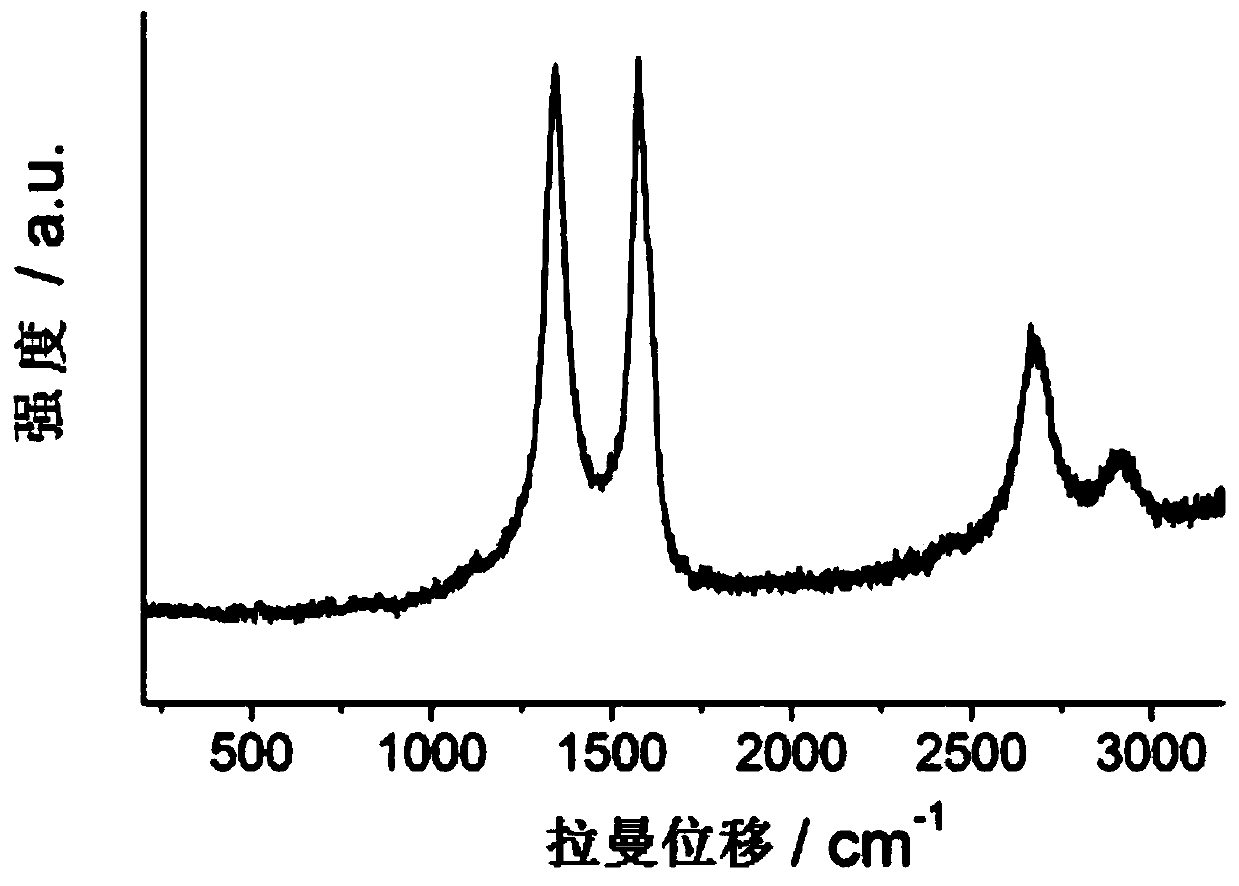

Embodiment 1

[0042] Dissolve 12.8g of phenolic resin in 50ml of absolute ethanol and stir until completely dissolved, add 2.23g of KCl and continue to stir until a suspension is formed, transfer the suspension to a polytetrafluoroethylene reactor for hydrothermal reaction, keep the temperature at 180°C, The holding time is 18h. After filtering, the product was washed three times with deionized water, and then dried in a vacuum oven at 60° C. for 10 h to obtain a two-dimensional carbon nanosheet precursor. Put 3.1 g of two-dimensional carbon nanosheet precursor in 50 mL of cobalt nitrate solution with a concentration of 2 mol / L, stir for 24 hours, and filter and dry to obtain a two-dimensional carbon nanosheet precursor that adsorbs transition metal ions. The precursor was carbonized under nitrogen atmosphere, the carbonization temperature was 900 °C, the carbonization time was 2 h, and the heating rate was 2 °C / min. Subsequently, the high-temperature carbonized product was repeatedly wash...

Embodiment 2

[0045] Dissolve 13.1g of phenolic resin in 50ml of absolute ethanol and stir until it is completely dissolved, add 3.34g of KCl and continue to stir until a suspension is formed, transfer the suspension to a polytetrafluoroethylene reactor for hydrothermal reaction, keep the temperature at 180°C, The holding time is 16h. After filtration, wash with deionized water for 3 times, and then dry in a vacuum oven at 60° C. for 10 h to obtain a two-dimensional carbon nanosheet precursor. Put 3.1 g of the two-dimensional carbon nanosheet precursor in 50 mL of ferric chloride solution with a concentration of 1 mol / L, stir for 24 hours, and filter and dry to obtain the two-dimensional carbon nanosheet precursor adsorbing transition metal ions. The precursor was carbonized under nitrogen atmosphere, the carbonization temperature was 1200°C, the carbonization time was 2h, and the heating rate was 2°C / min. Subsequently, the high-temperature carbonized product was repeatedly washed three ti...

Embodiment 3

[0048] Dissolve 9.8g of phenolic resin in 50ml of absolute ethanol and stir until completely dissolved, add 3.3g of KCl and continue to stir until a suspension is formed, transfer the suspension to a polytetrafluoroethylene reactor for hydrothermal reaction, and keep the temperature at 180°C. The holding time is 16h. After filtration, wash with deionized water for 3 times, and then dry in a vacuum oven at 60° C. for 10 h to obtain a two-dimensional carbon nanosheet precursor. Put 3.1 g of two-dimensional carbon nanosheet precursor in 50 mL of cobalt nitrate solution with a concentration of 3 mol / L, stir for 24 hours, and filter and dry to obtain a two-dimensional carbon nanosheet precursor that adsorbs transition metal ions. The precursor was carbonized under nitrogen atmosphere, the carbonization temperature was 900°C, the carbonization time was 2h, and the heating rate was 2°C / min. Subsequently, the high-temperature carbonized product was repeatedly washed with a dilute nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com