Preparation method of catalyst material for hydrogen production by virtue of electrolysis of water

A technology of catalyst and electrolysis of water, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, electrolysis process, etc., can solve the problems that hinder the expansion and application of electrochemical hydrogen production, high price resources, etc., and achieve large-scale continuous production , simple process, excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

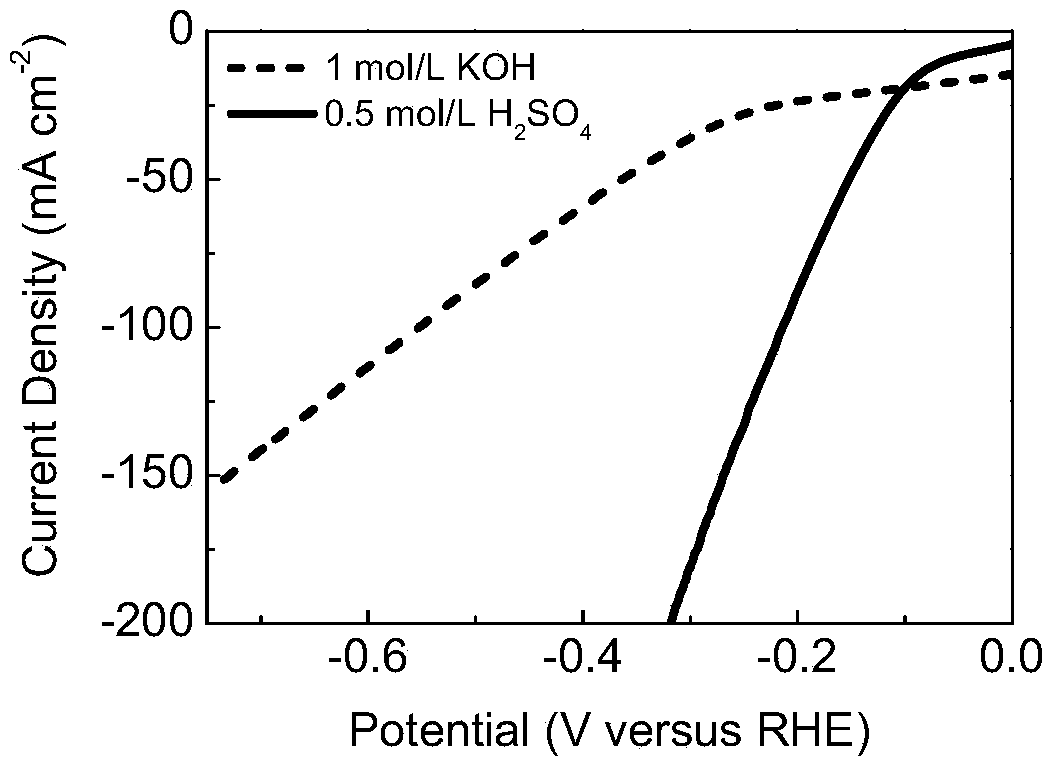

[0025] Control the precursor mass ratio of graphite carbon nanostructure-graphene composite carbon paper material to molybdenum and sulfur to be 1:1, soak graphite carbon nanostructure-graphene composite carbon paper in 1mol / L ammonium sulfomolybdate N,N - in dimethylformamide solution, reacted at 200°C for 12 hours, and finally cooled naturally, washed repeatedly with water and ethanol to obtain molybdenum sulfide and graphite carbon nanostructure-graphene composite carbon paper material, its scanning electron microscope photo is as follows figure 1 shown.

[0026] The carbon nanostructure-graphene composite carbon paper is prepared by the following method: using bacterial cellulose and urea as raw materials, mixing them at a mass ratio of 1:20, calcining at a temperature of 1000°C under the protection of nitrogen, and finally cooling naturally to obtain .

[0027] The prepared molybdenum sulfide and graphite carbon nanostructure-graphene composite carbon paper material can ...

Embodiment 2

[0029] Control the precursor mass ratio of graphite carbon nanostructure-graphene composite carbon paper material to molybdenum and sulfur to be 0.0001:1, soak graphite carbon nanostructure-graphene composite carbon paper in 1mol / L ammonium sulfomolybdate N,N - In dimethylformamide solution, react at 200°C for 12 hours, and finally cool naturally, and wash repeatedly with water and ethanol to obtain molybdenum sulfide and graphite carbon nanostructure-graphene composite carbon paper material.

Embodiment 3

[0031] Control the precursor mass ratio of graphite carbon nanostructure-graphene composite carbon paper material to molybdenum and sulfur to be 1:10000, soak graphite carbon nanostructure-graphene composite carbon paper in 1mol / L ammonium sulfomolybdate N,N - In dimethylformamide solution, react at 200°C for 12 hours, and finally cool naturally, and wash repeatedly with water and ethanol to obtain molybdenum sulfide and graphite carbon nanostructure-graphene composite carbon paper material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com