Preparing method and application of core-shell material catalyst

A catalyst and core-shell technology, which is applied in the field of preparation of new core-shell material catalysts, can solve problems such as difficult to break thermodynamics, and achieve the effects of repeated use, controllable morphology, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

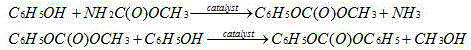

Method used

Image

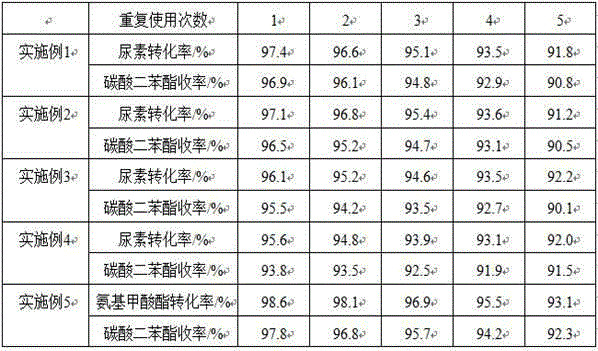

Examples

Embodiment 1

[0020] Embodiment 1: The method for preparing the zinc chloride catalyst coated with molecular sieves is as follows:

[0021] (1) Add 10mmol of anhydrous zinc chloride to a conical flask with 20mL of methanol as a solvent and a magnetic stirrer, and then add polyethylene glycol to the zinc chloride solution at the ratio of 100mg of surfactant to 1mL of the solution. Glycol, stirred for 10 minutes to make the whole solution system fully mixed; pass into ammonia gas containing 20% ammonia until the color of the solution no longer changes, and the precipitate obtained at this time is the saturated ammonia complex of zinc chloride, and the mixed solution Use a high-speed centrifuge to centrifuge, filter, and vacuum-dry at 50°C to obtain a solid powder of zinc ammonium chloride, and use a conventional Zeta potential analyzer to determine that the solid surface of zinc ammonium chloride is negatively charged;

[0022] (2) Preparation of molecular sieves

[0023] ① Press SiO2 2 :...

Embodiment 2

[0032] Embodiment 2: the method for preparing the cadmium chloride catalyst coated with molecular sieves is as follows:

[0033] (1) Add 8mmol of anhydrous cadmium chloride to a conical flask with 20mL of absolute ethanol as a solvent and a magnetic stirrer, and then add polyol to the cadmium chloride solution at the ratio of 1mL to 50mg of surfactant. Vinyl alcohol, stirred for 10 minutes to fully mix the entire solution system; pass through ammonia gas with an ammonia content of 20% until the color of the solution no longer changes, and the precipitate obtained at this time is the saturated ammonia complex of cadmium chloride. Use a high-speed centrifuge to centrifuge, filter, and vacuum-dry at 50°C to obtain cadmium chloride solid powder, and use a conventional Zeta potential analyzer to determine that the surface of the ammonium cadmium chloride solid is positively charged;

[0034] (2) The synthesis method of molecular sieve refers to the patent literature, and the specif...

Embodiment 3

[0044] Embodiment 3: the method for preparing the cobalt chloride catalyst coated with molecular sieve is as follows:

[0045] (1) Add 6mmol of anhydrous cobalt chloride to a 20mL conical flask with ethylene glycol as a solvent and a magnetic stirrer, and then add ten Hexaalkyltrimethylammonium bromide, stirred for 10 minutes to fully mix the entire solution system; pass through ammonia gas with an ammonia content of 20% until the color of the solution no longer changes, and the precipitate obtained at this time is saturated with cobalt chloride Ammonia complexes, the mixed solution is centrifuged with a high-speed centrifuge, filtered, and vacuum-dried at 50°C to obtain the cobalt ammonium chloride solid powder, which is determined to be negatively charged on the surface of the cobalt ammonium chloride solid by using a conventional Zeta potential analyzer;

[0046] (2) The preparation method of molecular sieve refers to relevant patent documents, and the specific implementati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com