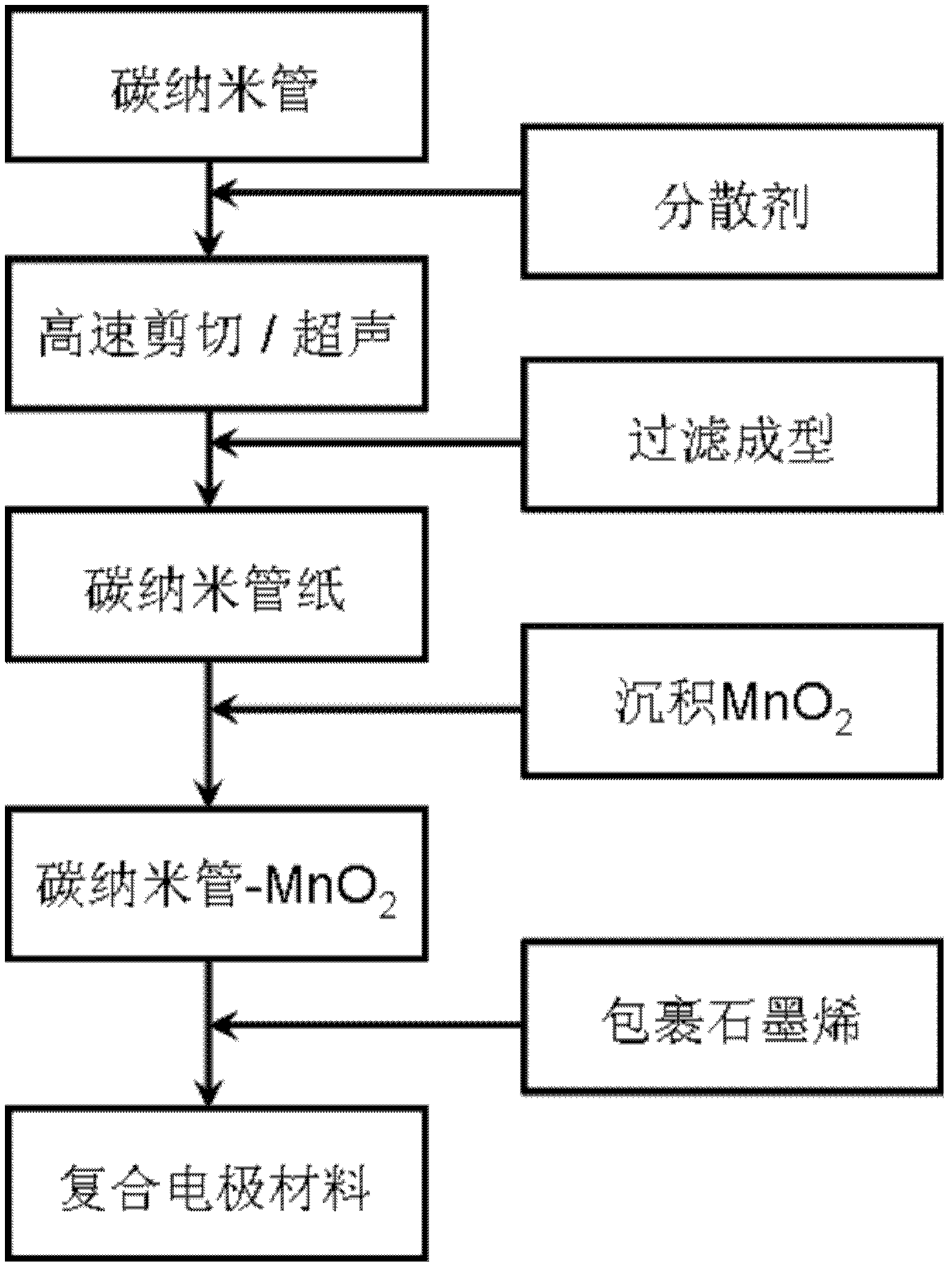

Composite nanometer carbon paper and preparation method thereof

A nanocarbon and carbon nanotube paper technology, applied in electrical components, electrolytic capacitors, capacitors, etc., can solve the problems of small maximum operating current, low power density, low power density, etc. The effect of flexible quality and high current charging and discharging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Example 1 Weigh 500 mg of carbon nanotubes purified by hydrochloric acid and disperse them in 1L of deionized water. The dispersant is polyvinylpyrrolidone. Stir for several minutes with a high-shear mixer until the carbon nanotubes form a slurry-like distribution in the dispersion. Cellulose filter paper was spread on the bottom of a Buchner funnel with a diameter of 25 cm, and was filtered with a vacuum pump to uniformly deposit carbon nanotubes on the filter paper. When it was half dry, the carbon nanotube paper was separated from the filter paper to obtain carbon nanotube paper. The thickness is about 65 um. Introduce the circular carbon nanotube paper into the wire along the four 90-degree directions of the central angle to make an electrode, and immerse the electrode in a mixed solution of 0.8mol / L sulfuric acid and 0.6mol / L manganese sulfate monohydrate for several minutes to make the electrolyte Fully infiltrate with carbon nanotube paper, and then carry out a...

Embodiment 2

[0066] Example 2 Weigh 120 mg of carbon nanotubes purified by hydrochloric acid, disperse them in 1 L of deionized water, use Delaton-100 as the dispersant, and stir them with a high-shear mixer for several minutes until the carbon nanotubes form a slurry-like distribution in the dispersion. Spread the cellulose filter paper on the bottom of the Buchner funnel, filter with a vacuum pump, so that the carbon nanotubes are evenly deposited on the filter paper, and separate the carbon nanotube paper from the filter paper when it is semi-dry to obtain a carbon nanotube paper with a diameter of 6 cm. The thickness is about 60 um. The circular carbon nanotube paper is introduced into the wire to make an electrode, and the electrode is immersed in a mixed solution of 1mol / L sodium acetate and 0.5mol / L manganese acetate for several minutes, so that the electrolyte and the carbon nanotube paper are fully infiltrated, and then circulated Voltammetric electrochemical deposition, the pot...

Embodiment 3

[0067] Example 3 Weigh 500 mg of carbon nanotubes purified by hydrochloric acid and disperse them in 1L of deionized water. The dispersant is sodium dodecylbenzenesulfonate (SDBS). Form a slurry distribution in the liquid, spread the cellulose filter paper on the bottom of a Buchner funnel with a diameter of 25 cm, filter with a vacuum pump, so that the carbon nanotubes are evenly deposited on the filter paper, and separate the carbon nanotube paper from the filter paper when it is semi-dry , to obtain carbon nanotube paper, the thickness of which is about 65 um. Introduce the circular carbon nanotube paper into the wire along the four 90-degree directions of the central angle to make an electrode, and immerse the electrode in a mixed solution of 0.8mol / L sulfuric acid and 0.6mol / L manganese sulfate monohydrate for several minutes to make the electrolyte Fully infiltrate with carbon nanotube paper, and then carry out anode constant voltage electrochemical deposition, the dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com