Carbon nano tube electrode formed by directly growing carbon nano tube on surface of carbon paper and supporting platinum-based nano catalyst on carbon nano tube using CVD method and manufacturing met

A nanocatalyst, carbon nanotube technology, applied in catalyst activation/preparation, physical/chemical process catalysts, nanotechnology for materials and surface science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

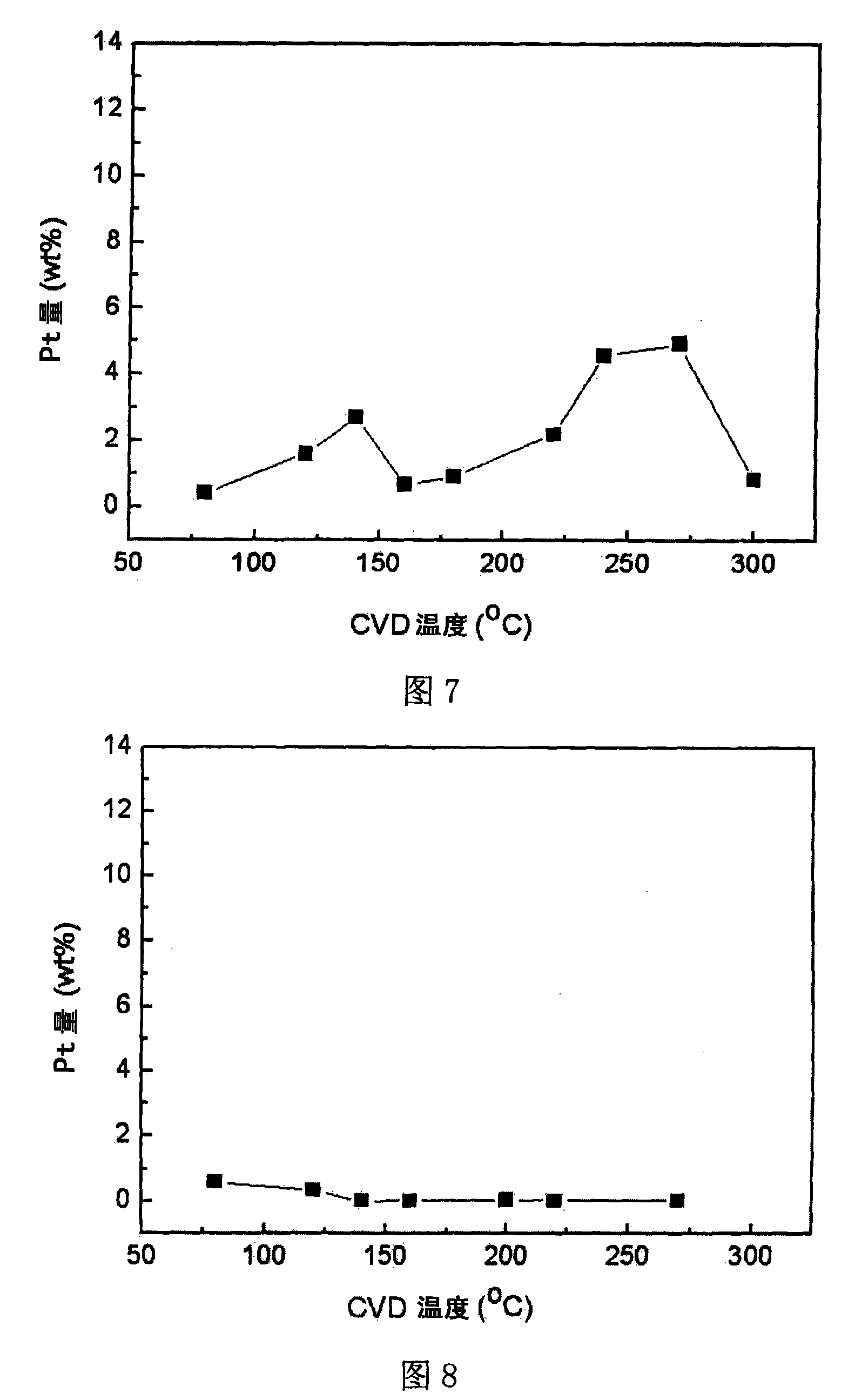

Embodiment 1

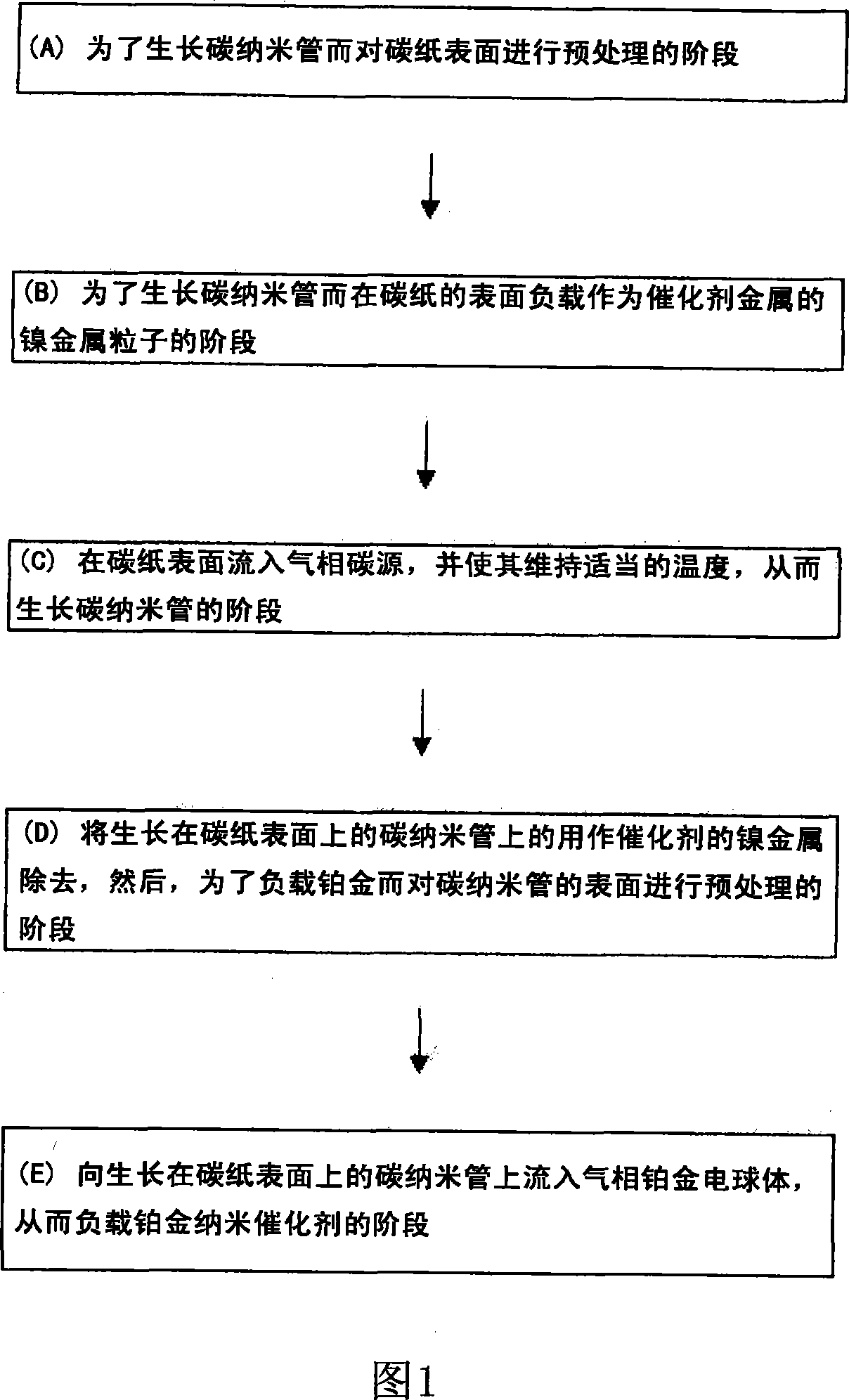

[0064] A. Stages of pretreatment of carbon paper for carbon nanotube growth

[0065] - In order to enhance the wettability of carbon paper, soak carbon paper with a length and width of 2cm in 0.5mol sulfuric acid aqueous solution, and then treat it for 60 times at a scan rate of 50mV / s under the condition of -0.15~1.3V . Then, the treated carbon paper was repeatedly washed with distilled water for several times, and then put into an oven at 110° C. for drying treatment for 12 hours.

[0066] B. The stage of supporting catalysts for growing carbon nanotubes on the surface of pretreated carbon paper:

[0067] Soak the pretreated carbon paper in stage A in nickel aqueous solution (0.25mol) using nickel nitrite as electric spheres, then apply ultrasonic waves (60Hz) for 5 minutes, and repeat this procedure for 5 times, thereby loading nickel on the surface of carbon paper. Nickel particles can be efficiently loaded by placing them in the air for drying between the various stage...

Embodiment 2

[0078] In the E stage, except that the reaction temperature in the quartz tube provided with the carbon paper loaded with gas-phase platinum electric spheres reaches 80° C., the rest of the steps are processed in the same way as in the A-E stages in Example 1.

Embodiment 3

[0080] In the E stage, except that the reaction temperature in the quartz tube provided with the carbon paper carrying the gas-phase platinum electric spheres reached 120°C, the rest of the steps were processed in the same way as in the A-E stages in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com