Nitrogen-doped porous carbon and preparation method thereof

A technology of porous carbon and nitrogen doping, which is applied in the preparation/purification of carbon, etc., which can solve the problems of low utilization rate of nitrogen source, complex preparation process, and low nitrogen content of materials, and achieve a wide range of raw material selection, easy operation, and high efficiency The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

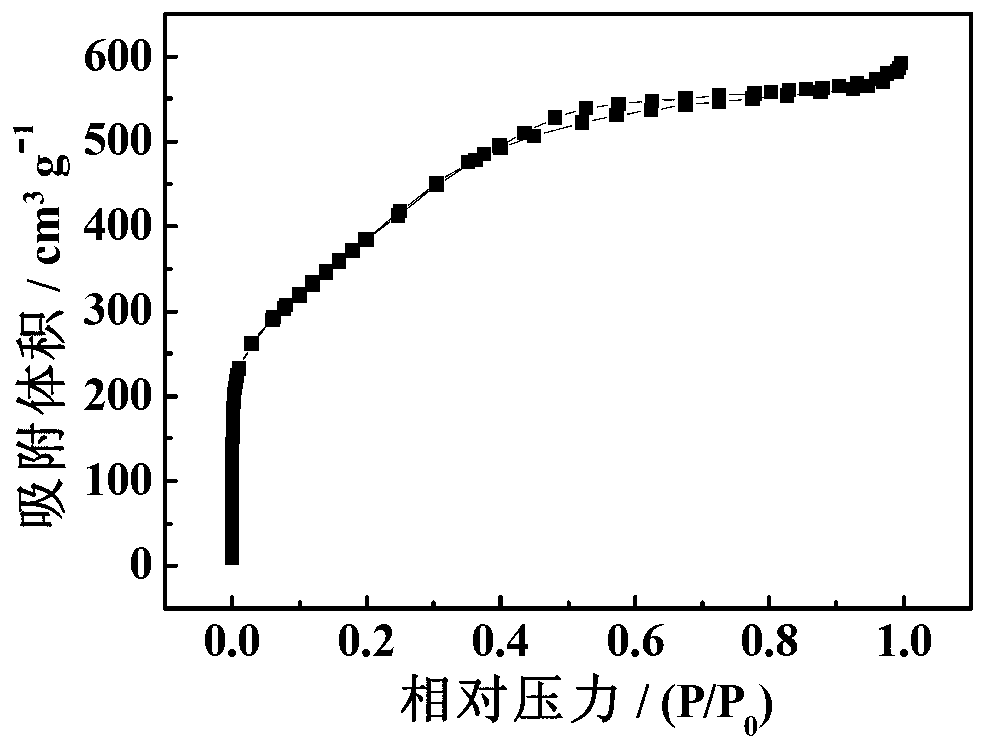

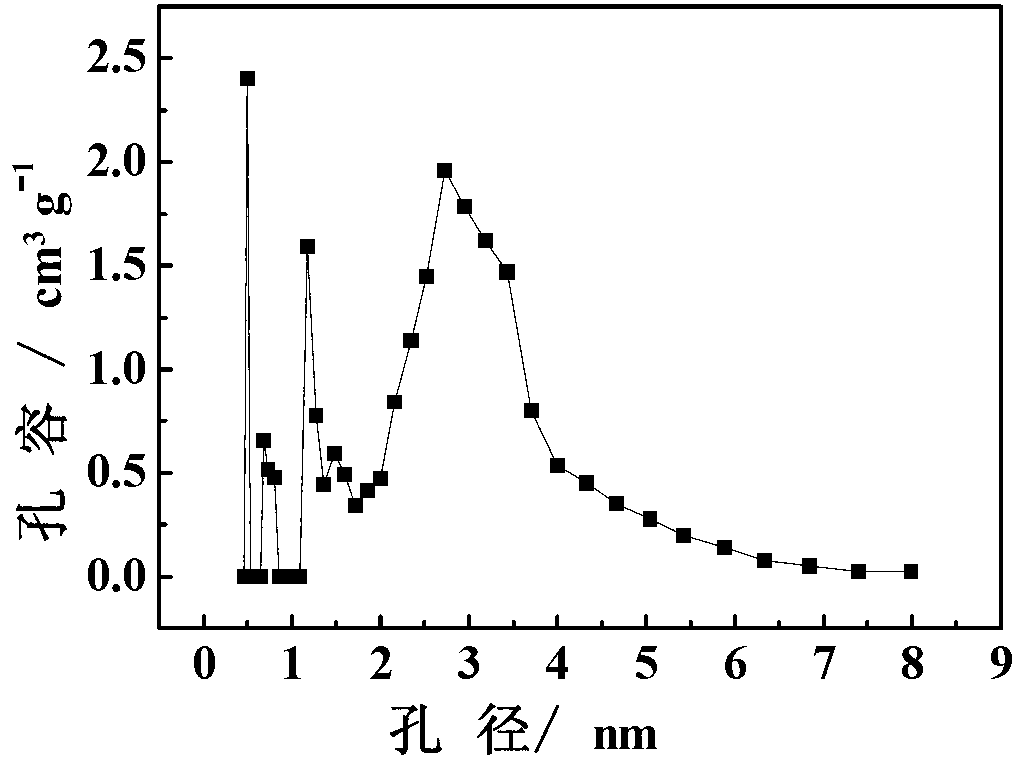

Embodiment 1

[0031] Mix melamine and formaldehyde at a molar ratio of 1:6, adjust the pH to 8 with sodium hydroxide, and bathe in water at 60°C for 30 minutes to obtain a clear solution A; The ratio of coal tar pitch to tetrahydrofuran is 1g:25mL. Dissolve coal tar pitch in tetrahydrofuran, and add magnesium citrate according to the mass ratio of coal tar pitch to magnesium citrate as 1:3, and mix well to obtain mixed solution B; The mixture B is mixed, and the reaction time is 5h at 80°C to make it fully cross-linked and blended. The residual solvent in the resulting blend is evaporated to dryness and cured at 150°C for 12h; in a carbonization furnace, under a helium atmosphere of 50mL / min , heated up to 700°C at a heating rate of 1°C / min, carbonized for 5 hours, washed with acid and water, and dried to obtain nitrogen-doped porous carbon. The main properties of the porous carbon are shown in Table 1.

Embodiment 2

[0033]Mix melamine and formaldehyde at a molar ratio of 1:1, adjust the pH to 7 with sodium hydroxide, and bathe in water at 90°C for 10 minutes to obtain a clear solution A; weigh it according to the mass ratio of coal liquefaction by-product asphaltenes to melamine at 1:5 Coal liquefaction by-product asphaltene, according to the ratio of coal liquefaction by-product asphaltene and tetrahydrofuran is 1g:15mL Dissolve coal liquefaction by-product asphaltene in tetrahydrofuran, and according to the mass of coal liquefaction by-product asphaltene and polyvinyl butyral Add polyvinyl butyral at a ratio of 1:5, mix thoroughly and evenly to obtain mixed solution B; mix solution A with mixed solution B, and react for 24 hours at 20°C to fully cross-link and blend, and blend the obtained solution The residual solvent in the product was evaporated to dryness, and solidified at 200°C for 1h; in a carbonization furnace, under a nitrogen atmosphere of 150mL / min, the temperature was raised ...

Embodiment 3

[0035] Mix urea and formaldehyde at a molar ratio of 1:3, adjust the pH to 9 with sodium hydroxide, and bathe in water at 40°C for 60 minutes to obtain a clear solution A; weigh it according to the mass ratio of coal liquefaction by-product asphaltenes to urea at 1:3 Coal liquefaction by-product asphaltene, according to the ratio of coal liquefaction by-product asphaltene and tetrahydrofuran is 1g:20mL Dissolve coal liquefaction by-product asphaltene in tetrahydrofuran, and the mass ratio of coal liquefaction by-product asphaltene to magnesium citrate is 1 : 0.5 Add magnesium citrate, mix well and get mixed solution B; mix solution A with mixed solution B, react at 90°C for 1 hour, make it fully cross-linked and blend, evaporate the residual solvent in the resulting blend to dryness , cured at 100°C for 24h; in a carbonization furnace, under a nitrogen atmosphere of 300mL / min, the temperature was raised to 1000°C at a rate of 10°C / min, carbonized for 0.5h, washed with acid and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com