Catalyst for heavy oil catalytic cracking and preparation method thereof

A catalytic cracking and catalyst technology, applied in catalytic cracking, cracking, petroleum industry, etc., can solve the problem of low utilization rate of rare earth, and achieve the effect of simple and easy preparation process, short process and strong cracking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

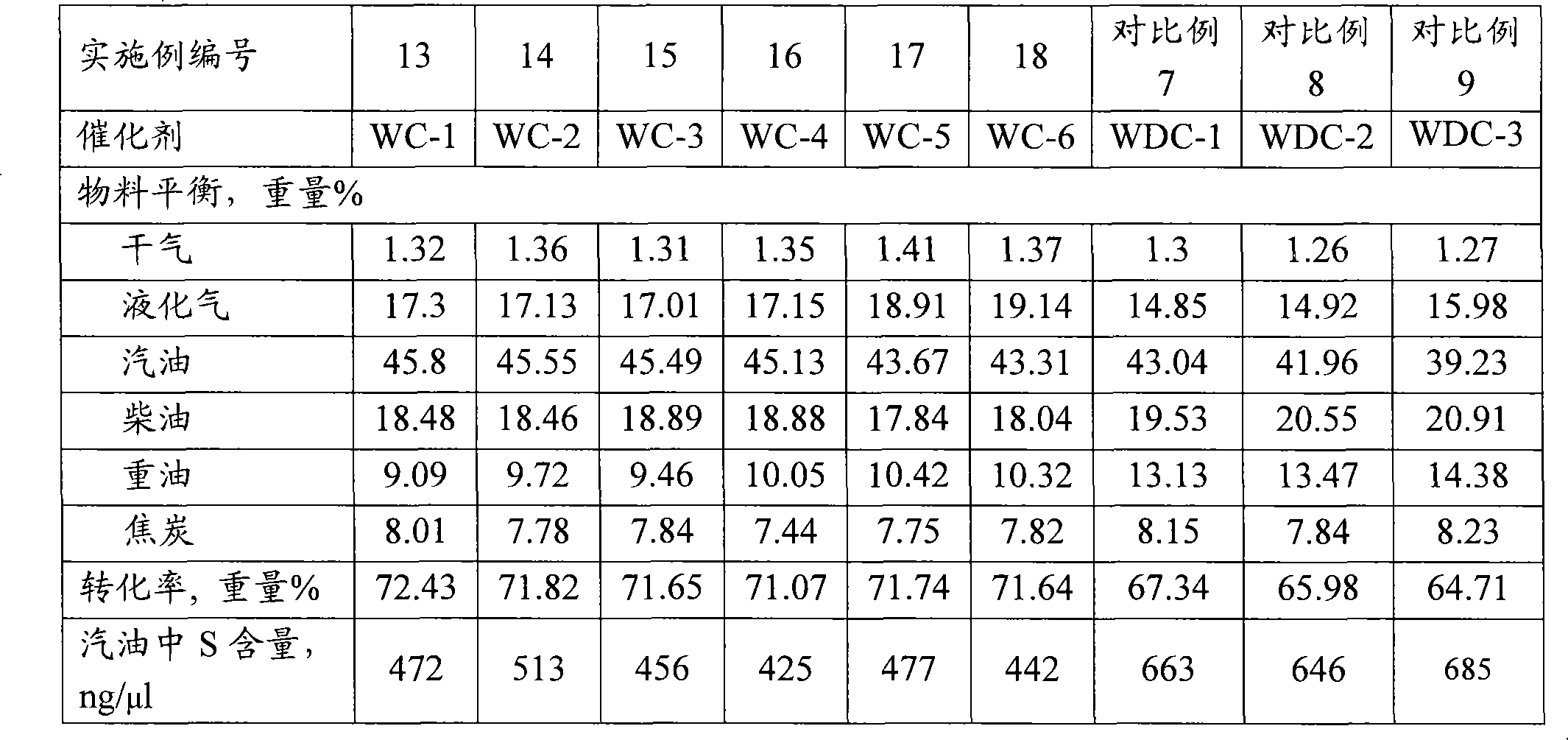

Examples

preparation example Construction

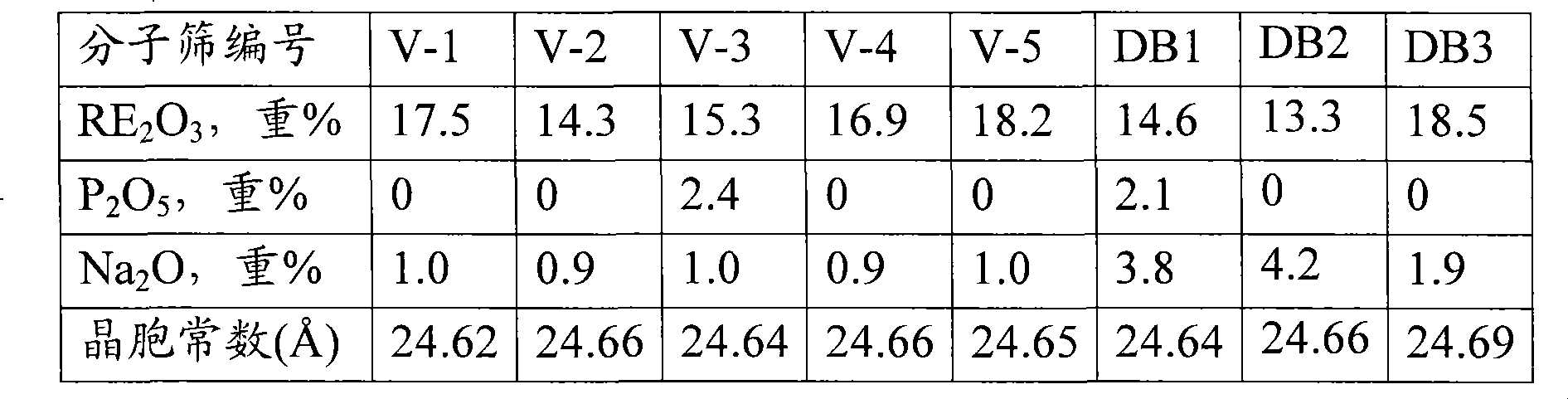

[0033] According to catalyst provided by the present invention, described REY molecular sieve preparation method comprises the following steps:

[0034] (1) Contact NaY molecular sieve with a silicon-aluminum ratio ≥ 4.5 with an aqueous solution containing rare earth ions or with an aqueous solution containing rare earth ions and an aqueous solution containing aluminum ions, wherein, in terms of rare earth oxides, the ratio of rare earth ions to molecular sieve solids is preferred 0.12-0.30, more preferably 0.13-0.20, based on alumina, the ratio of aluminum ions to molecular sieve solids is 0-0.1, preferably 0-0.05, the liquid-solid ratio is 4-20, preferably 8-15, and the reaction temperature is 60- 95°C, preferably 70-80°C, the reaction time is 10-120min, the ratio is a weight ratio, adding an alkaline aqueous solution to the reaction slurry, filtering and washing to obtain a filter cake product;

[0035] (2) performing hydrothermal treatment on the filter cake product obtain...

Embodiment 1

[0057] This example illustrates the catalyst provided by the invention and its preparation method.

[0058] (1) Get 1500 grams of NaY molecular sieves (dry basis weight, produced by Qilu Catalyst Factory, the same below), after beating with 12 liters of deionized water, add a concentration of 231g / l (based on RE 2 o 3 meter) mixed RECl 3 Solution (Qilu Catalyst Factory provides, wherein La 2 o 3 52.5% by weight, CeO 2 Accounting for 46.5% by weight, Pr 2 o 5 0.6% by weight, Nd 2 o 3 Accounting for 0.4% by weight, the same below) 1059 ml, exchanged at 80 ° C for 0.5 hours, then added 150 grams of ammonium bicarbonate (chemically pure, produced by Tianjin Nankai Chemical Factory, the same below), stirred at 80 ° C for 0.5 hours, filtered and rinsed , and then roast the filter cake at 650° C. in a 100% water vapor atmosphere for 2 hours to obtain a molecular sieve dry powder. Take 1500 grams of this molecular sieve dry powder (dry basis weight), beat with 12 liters of de...

Embodiment 2

[0062] This example illustrates the catalyst provided by the invention and its preparation method.

[0063] (1) The preparation method of molecular sieve V-1 is the same as that in Example 1.

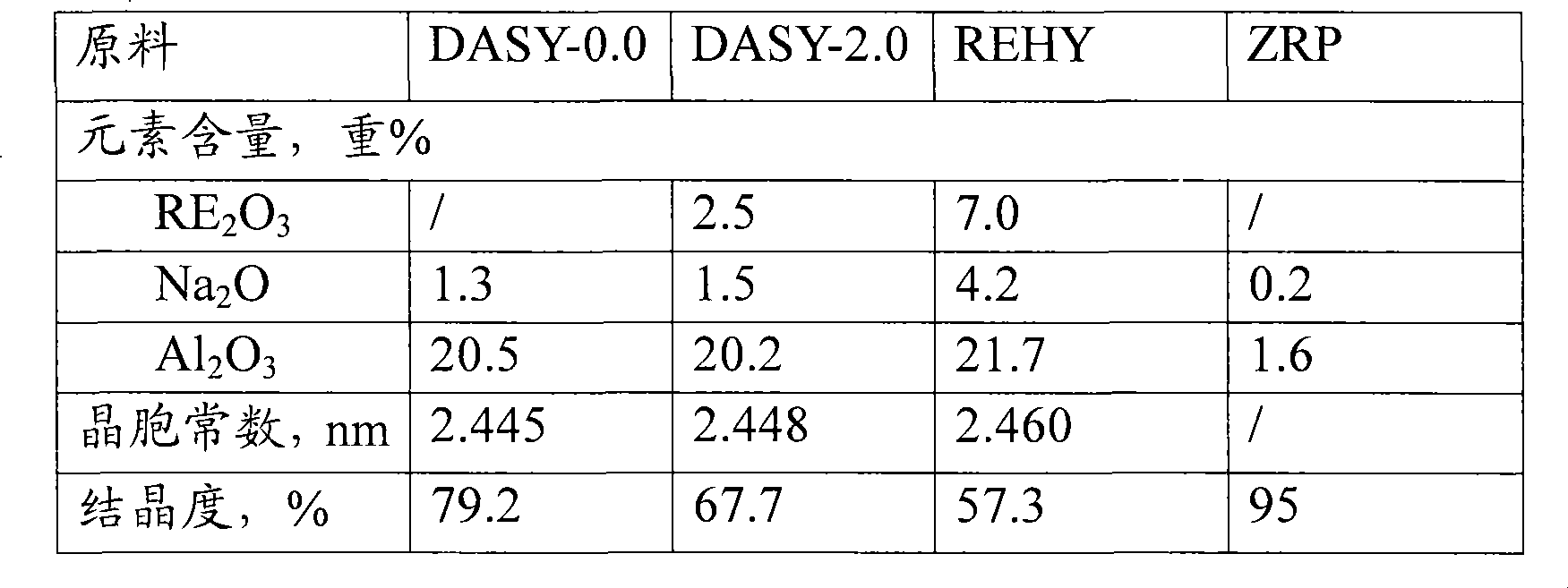

[0064] (2) Mix 1150 grams of pseudo-boehmite (produced by Shandong Aluminum Factory, alumina content 60%), 6000 grams of deionized water and 83 grams of hydrochloric acid (concentration 36%, produced by Beijing Chemical Plant, analytically pure) under stirring (the weight ratio of acid to alumina is 0.12), aging at 80°C for 1 hour, adding 154 grams of ZnO, 158 grams of TiO 2 (ZnO and TiO 2 Both are produced by Beijing Shuanghuan Reagent Factory, analytically pure), to obtain modified hydrated alumina A-2 containing zinc and titanium and having a pseudo-boehmite structure.

[0065] (3) Molecular sieve V-1 obtained in (1), DASY0.0 ultrastable molecular sieve, modified alumina hydrate A-2 obtained in (2), aluminum sol, kaolin according to the ratio of 20:17:27:11:25 The weight ratio is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com