Catalytic conversion method for vegetable fat and/or animal oil and fat

A technology for animal oils and vegetable oils, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, molecular sieve catalysts, etc., can solve the problems of not fully and effectively utilizing straight-chain hydrocarbon groups, and achieve high conversion capacity and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

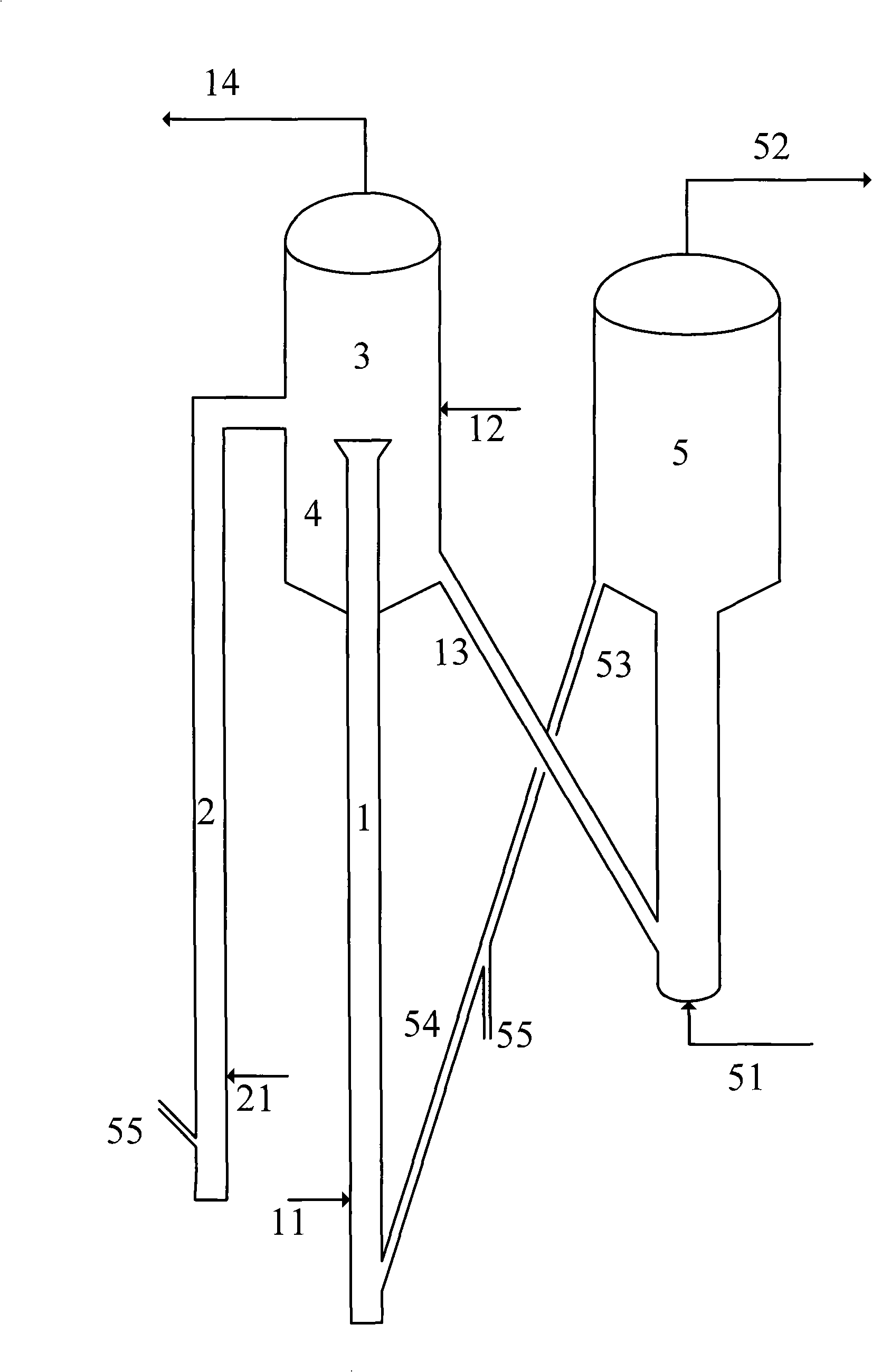

Method used

Image

Examples

Embodiment 1~4

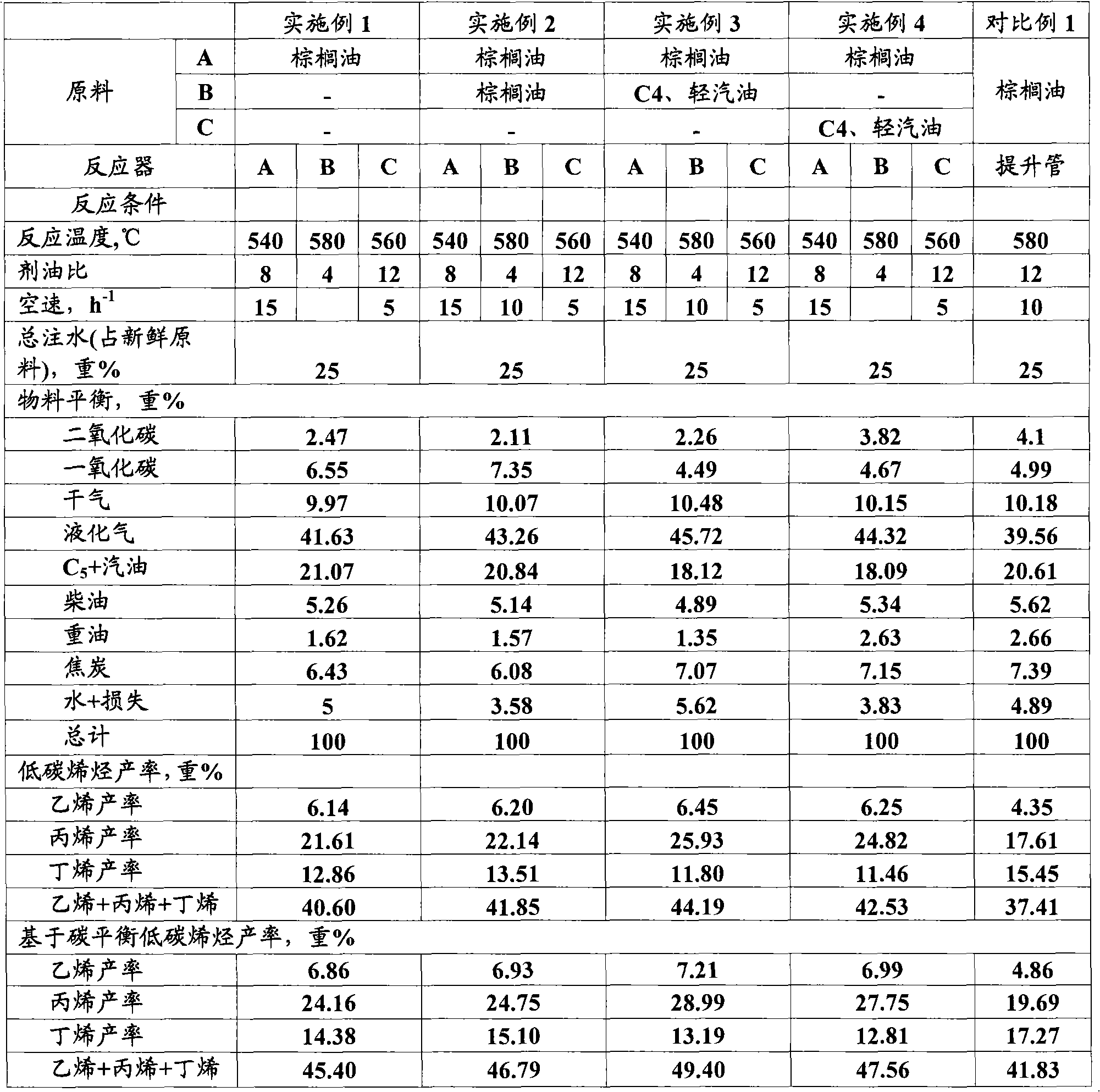

[0034] Examples 1-4 illustrate the effect of using the vegetable oil or / and animal oil catalytic conversion method provided by the present invention.

[0035] The catalyst (containing 10% by weight of zeolite beta, 20% by weight of ZSM-5 zeolite, and the balance as a carrier, all based on the total weight of the catalyst) was aged at 800°C with 100% steam for 10 hours, using a medium-sized test device, compounded The catalyst loading in the reactor was 60 kg.

Embodiment 1

[0036] Palm oil only enters riser reactor 1 among the embodiment 1;

Embodiment 2

[0037] In Example 2, 80% palm oil enters riser reactor 1, and 20% palm oil enters riser reactor 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com