Heavy slag oil fixed bed hydrogenating treatment process

A technology for hydrotreating and residual oil hydrogenation, applied in refining to remove heteroatoms, etc., can solve the problems of impossible to improve the activity of the protection catalyst and demetallization catalyst, low level of impurity removal, clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

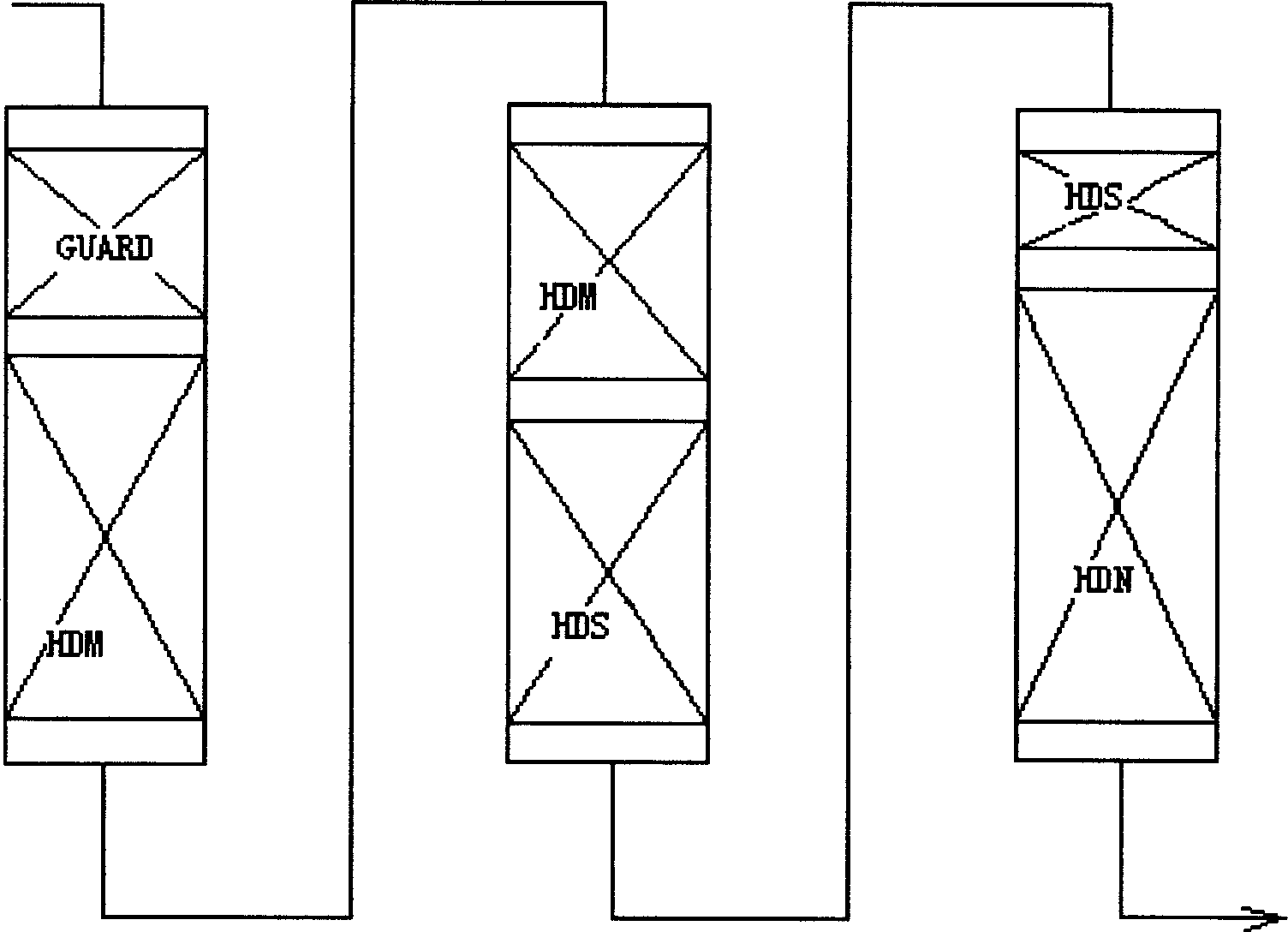

Image

Examples

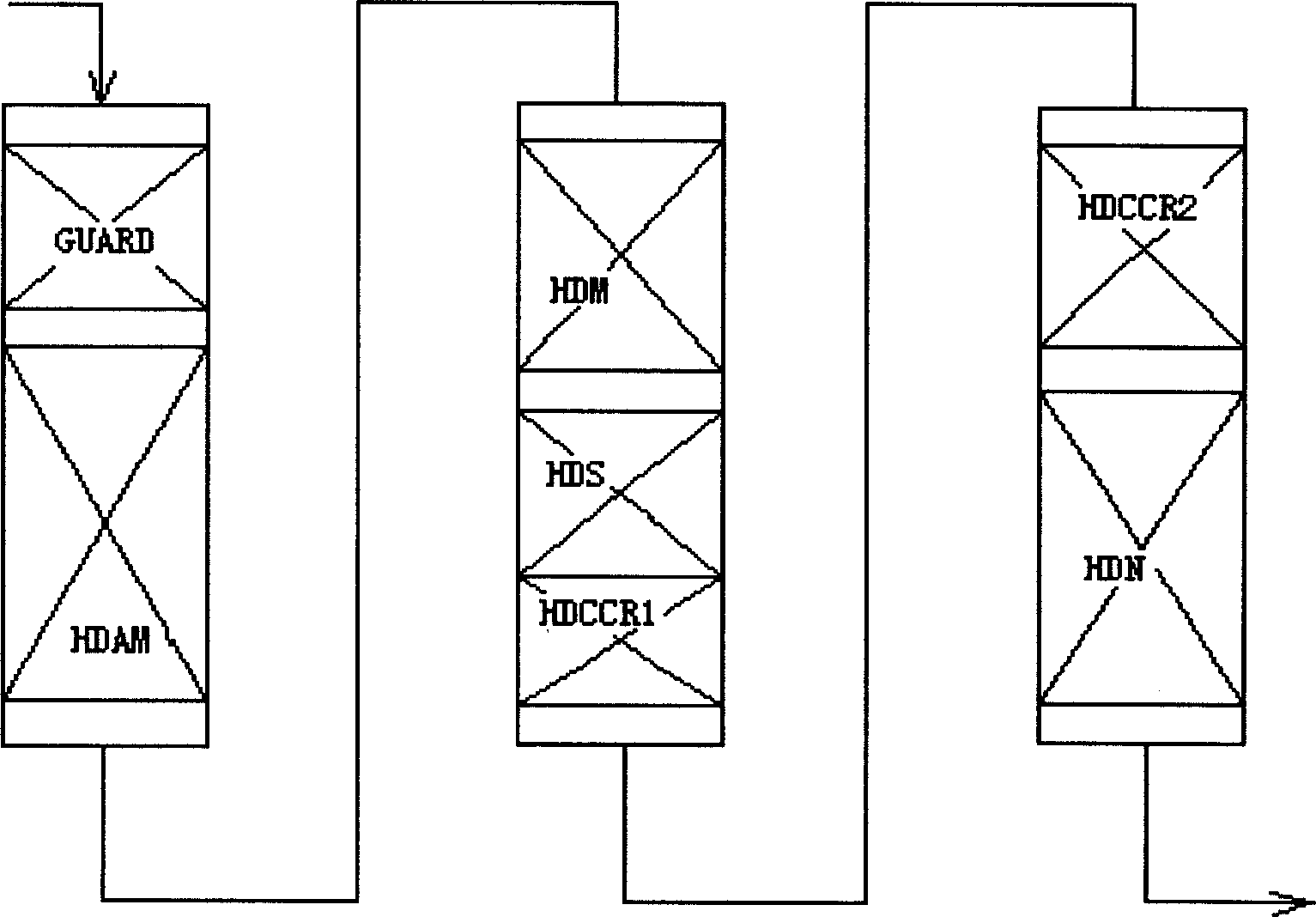

Embodiment 1

[0028] The volume ratio of GUARD and HDM is constant, the HDS loading capacity is reduced by 50%, and the HDN loading capacity is reduced by 50%, which are replaced by HDCCR1-1 and HDCCR2-1 respectively, and the volume ratio of the two catalysts is 3: 5. location such as figure 2 shown.

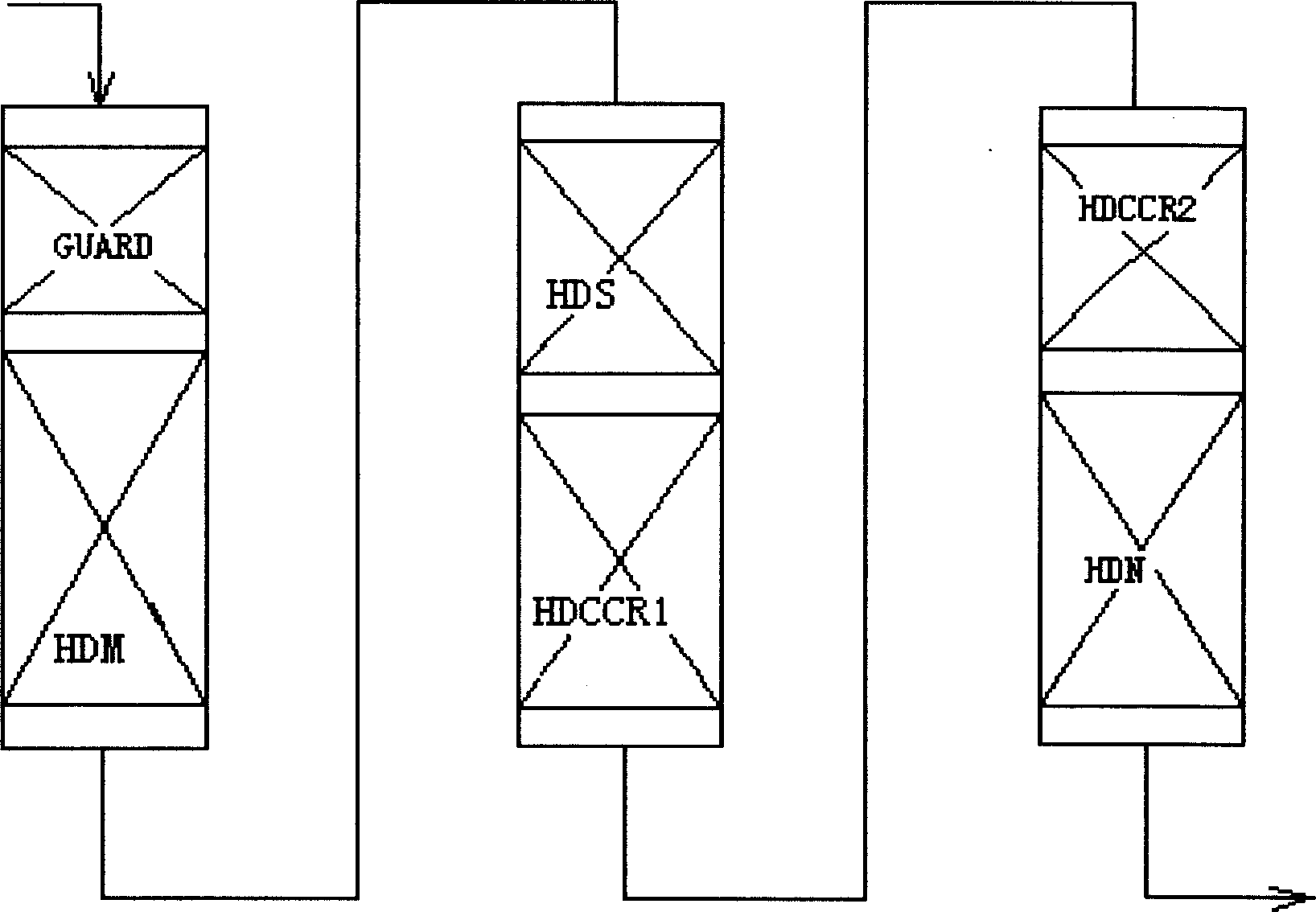

Embodiment 2

[0030] HDM loading is reduced by 40%, HDS is maintained unchanged, HDN loading is reduced by 40%, and carbon removal catalysts HDCCR1-1 and HDCCR2-2 are used instead, the volume ratio of the two catalysts is 3: 2, and its position in the reactor like image 3 shown.

Embodiment 3

[0032] In Example 1, HDCCR1-1 is replaced by HDCCR1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com