Hydrogenation method for liquefied gas fraction

A technology for liquefied gas and distillate, which is applied in the field of hydrogenation and saturation of light hydrocarbons, can solve problems such as no complete set of technologies and product solutions, research on hydrogenation technology of liquefied gas fractions, etc. High rate and the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

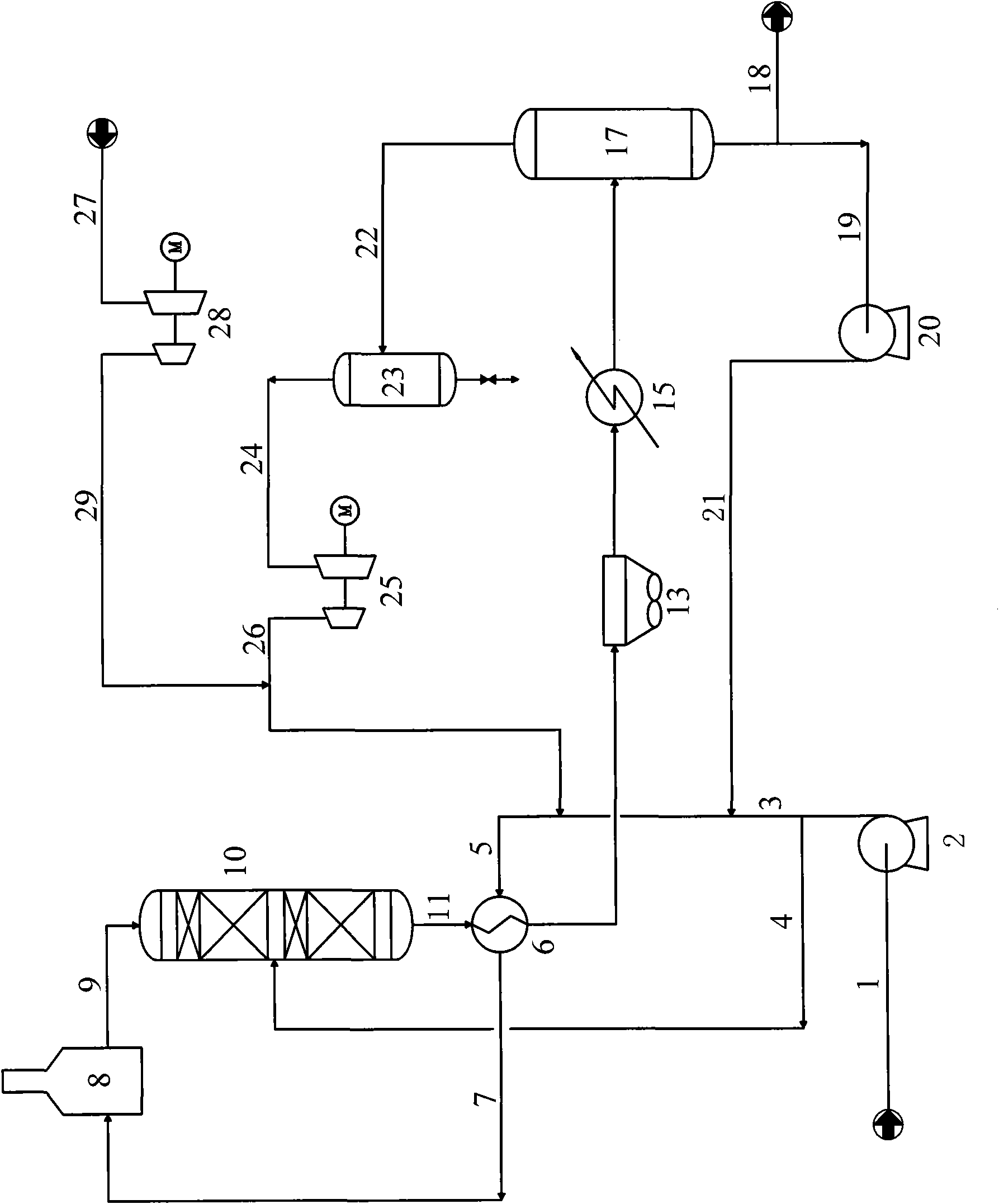

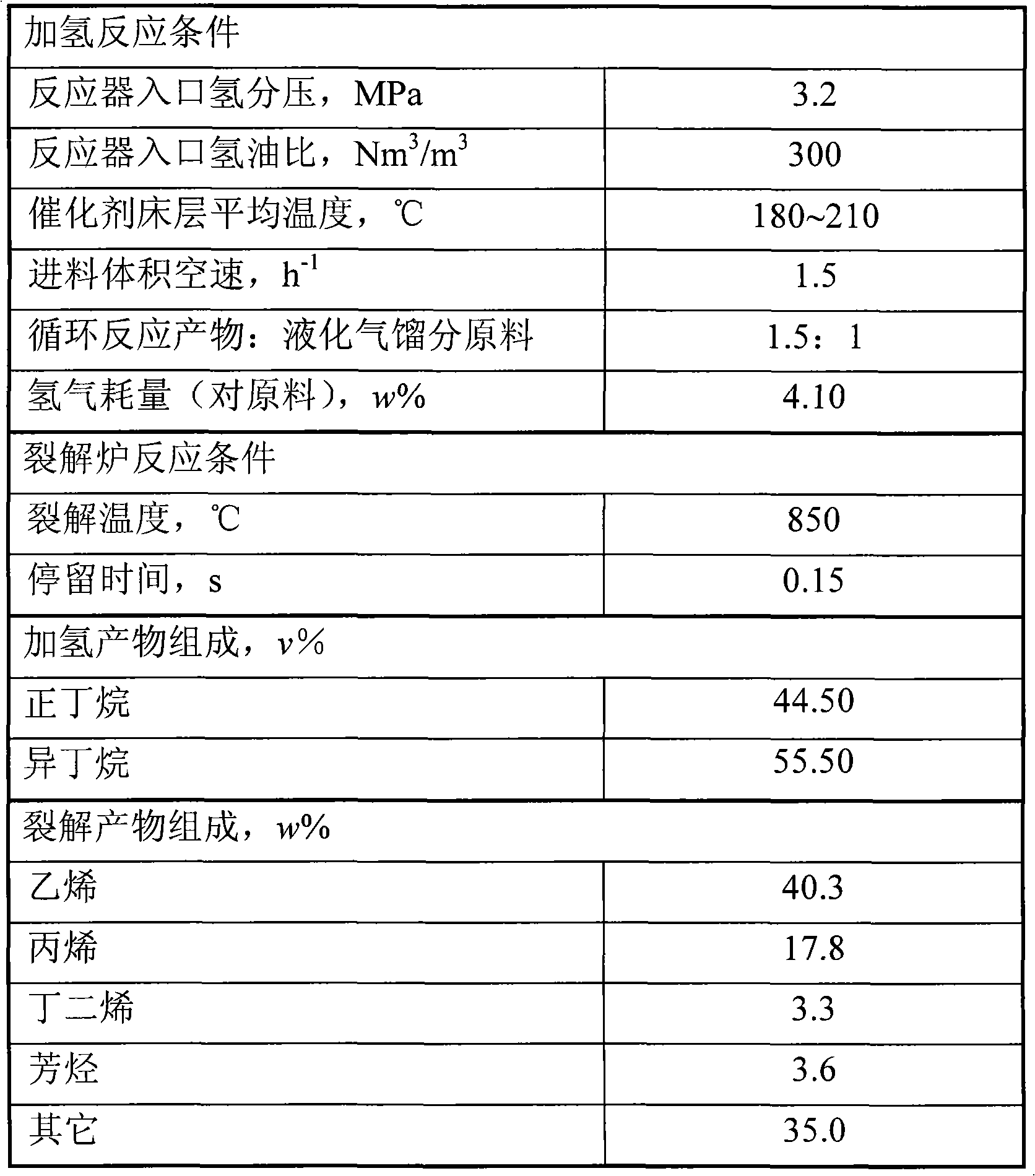

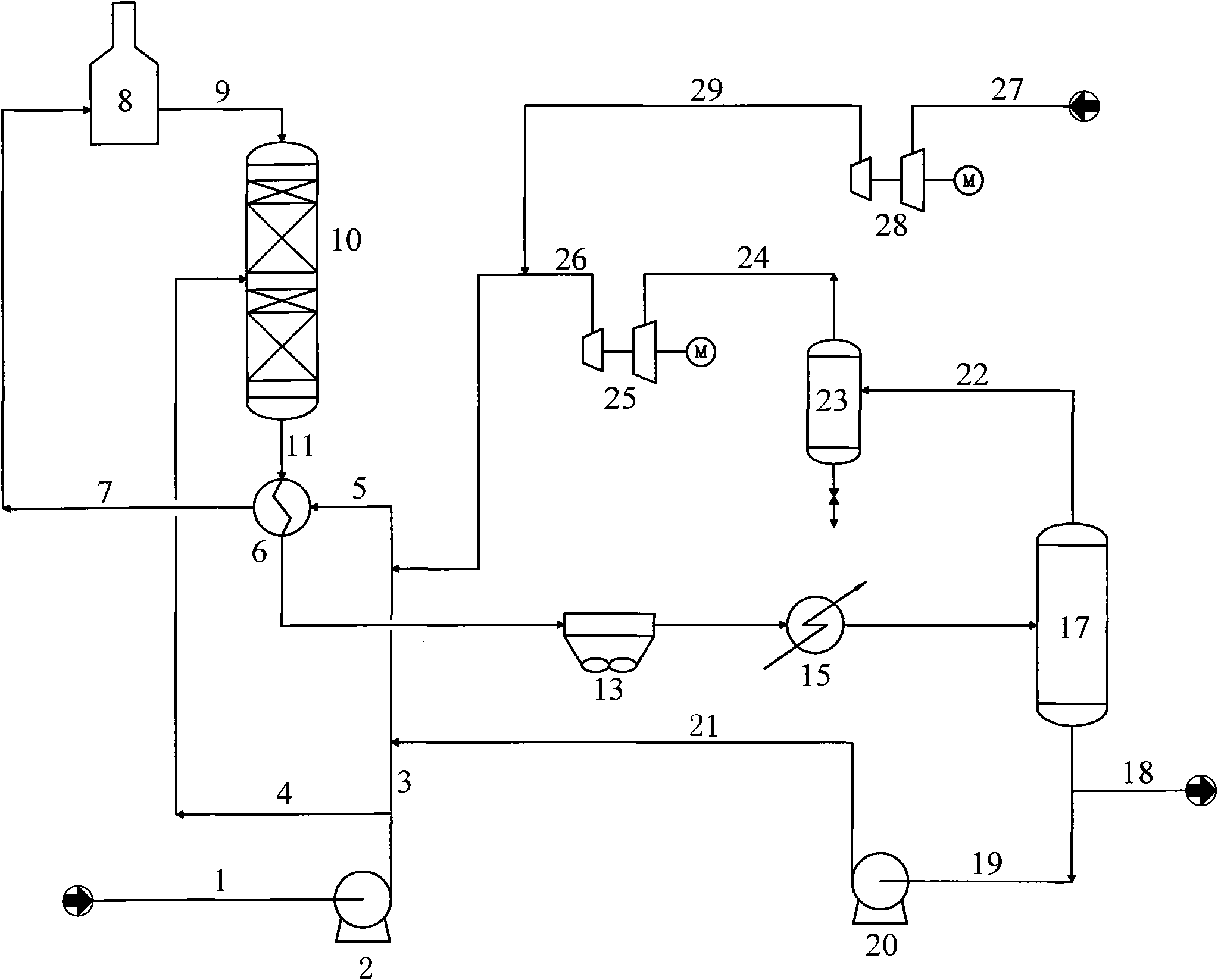

[0028] The process flow of the hydrogenation part of the raw material of the liquefied gas fraction in the embodiment is shown in the attached figure. The raw material of the liquefied gas fraction is mixed with the circulating reaction product and circulating hydrogen respectively, and enters the hydrogenation reactor after heat exchange and heating. The hydrogenation reactor is filled with a selective dedienization catalyst (trade name: RGO-2) and a hydrogenation saturation catalyst (trade name: RS-1), and the filling volume ratio of the two is 2:8. Both RGO-2 and RS-1 are produced by Sinopec Catalyst Changling Branch. Part of the hydrogenation reaction product is taken out of the reaction unit and introduced into the ethylene cracking furnace as the raw material for the ethylene cracking unit. The composition of the liquefied gas fraction raw material is shown in Table 1, the hydrogen composition is shown in Table 2, and the hydrogenation reaction conditions, hydrogenation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com