Turbine fracturing equipment

A turbine and equipment technology, applied in mechanical equipment, cooling of turbine/propulsion, gear transmission, etc., can solve the problems of pollution, transportation restrictions, engine exhaust pollution and noise, etc., to reduce the use cost, efficient transmission performance, Guaranteed transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

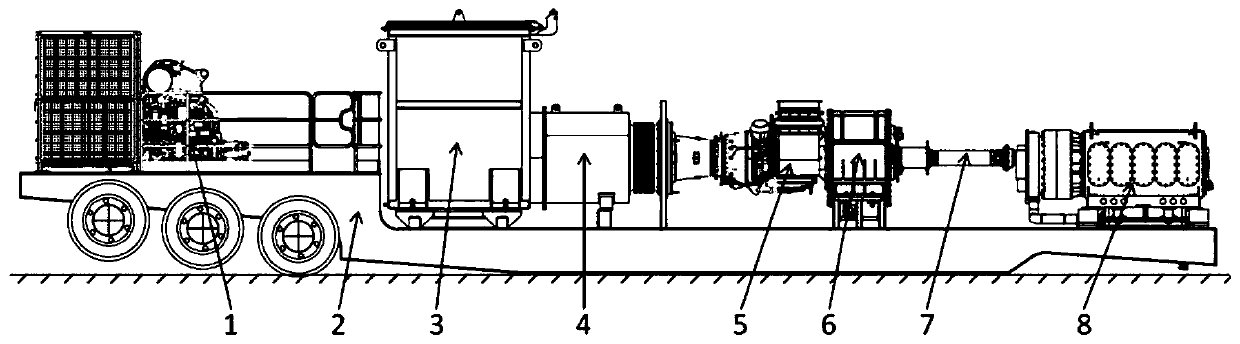

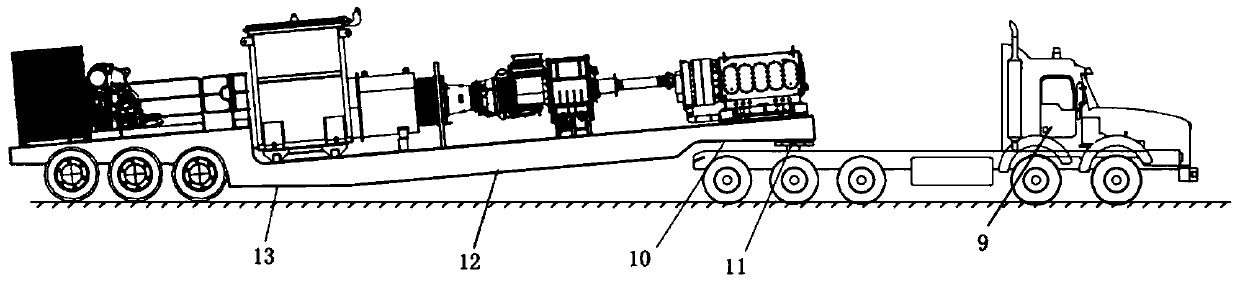

[0030] like Figures 1 to 2 Shown, a kind of turbine fracturing equipment, described turbine fracturing equipment comprises transportation device 2, turbine engine 5, reduction box 6, transmission mechanism 7 and fracturing pump 8, and described turbine engine 5 is the vehicle power transmission system Power source, the output end of the turbine engine 5 is connected to one end of the reduction box 6, the other end of the reduction box 6 is connected to the fracturing pump 8 through a transmission mechanism 7, and the transportation device 2 is used to carry the turbine engine 5, A reduction box 6, a transmission mechanism 7 and a fracturing pump 8, the transportation device 2 includes a chassis, the chassis is provided with a transportation section, a carrying section and an overlapping section, and the transportation section, the carrying section and the overlapping section are connected in sequence, When the turbine fracturing equipment is working, the bearing section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com