Musk processing and packaging equipment

A kind of packaging equipment and musk technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of not being able to clean up musk impurities and hair, not having heating function and screening function, and not realizing automation, so as to improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

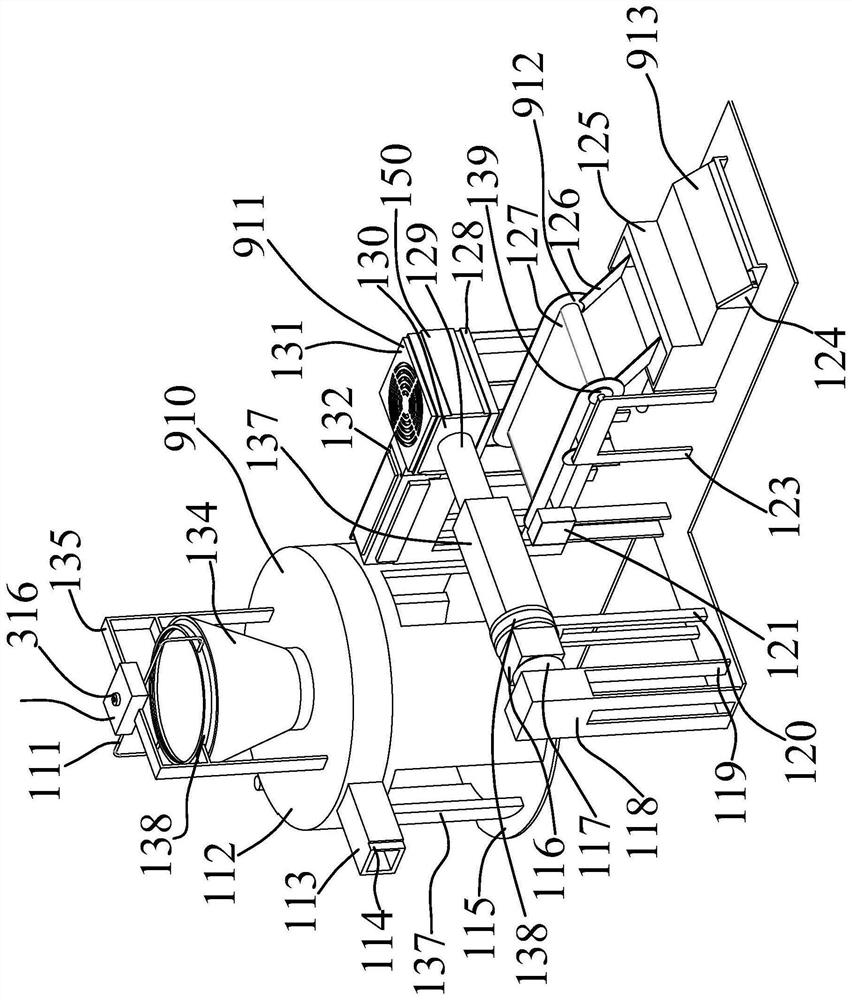

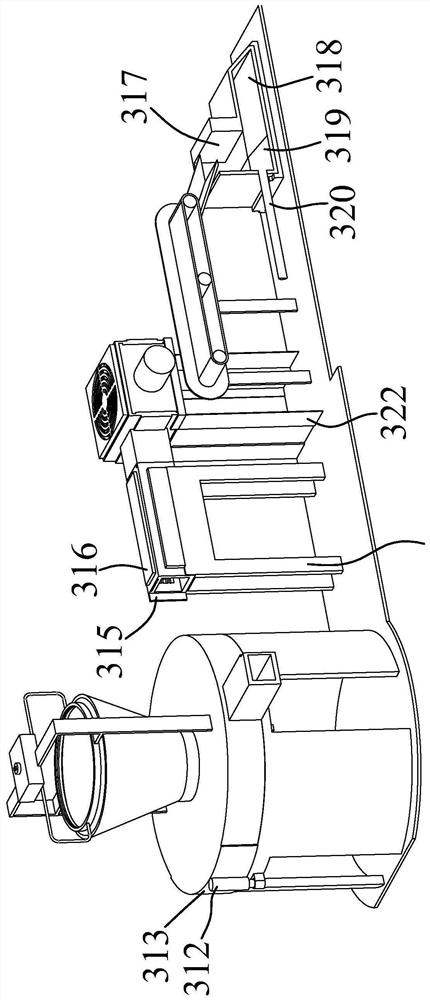

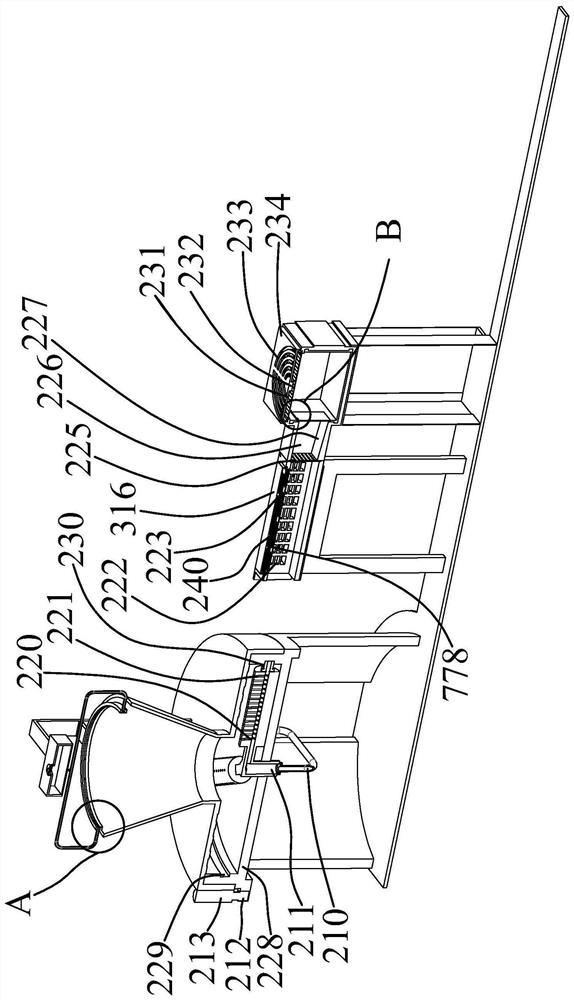

[0029] Such as Figure 1-Figure 5 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent. A musk processing and packaging equipment of the present invention includes a base 115, which is connected by sheet metal welding. Module 910, the right end of the cleaning and dilution module 910 is installed with a heating filter module 911 for heating and distilling the musk after cleaning. The right end is installed with a press-packing module 913 for packaging the processed musk, so that the cleaning, dilution, heating and screening of the musk are completed through the above-mentioned module, and finally packaged into blocks.

[0030] Beneficially, wherein, the cleaning and dilution module 910 includes a main body fixing frame 137 fixed on the upper end of the base 115,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com