Self-exhausting type safe injector

A safety syringe and self-exhausting technology, applied in the field of syringes, can solve problems such as affecting injection efficiency and complicated operation, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

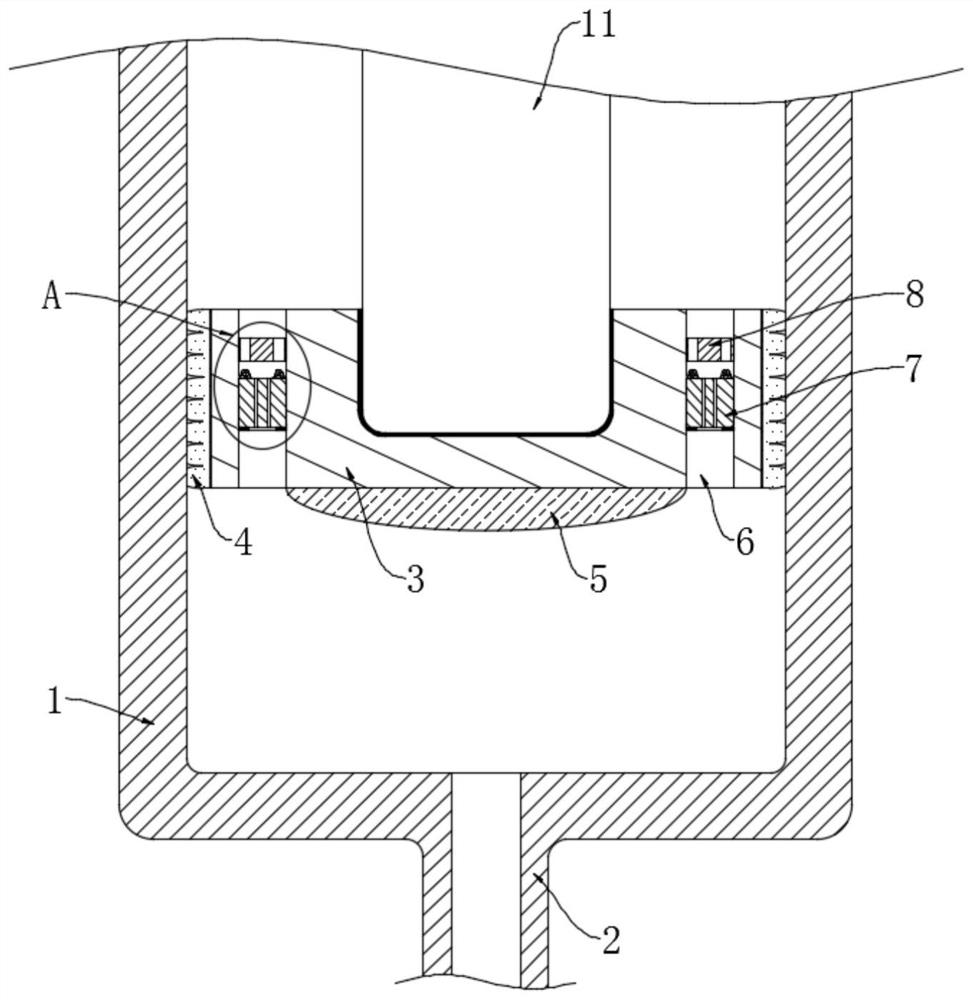

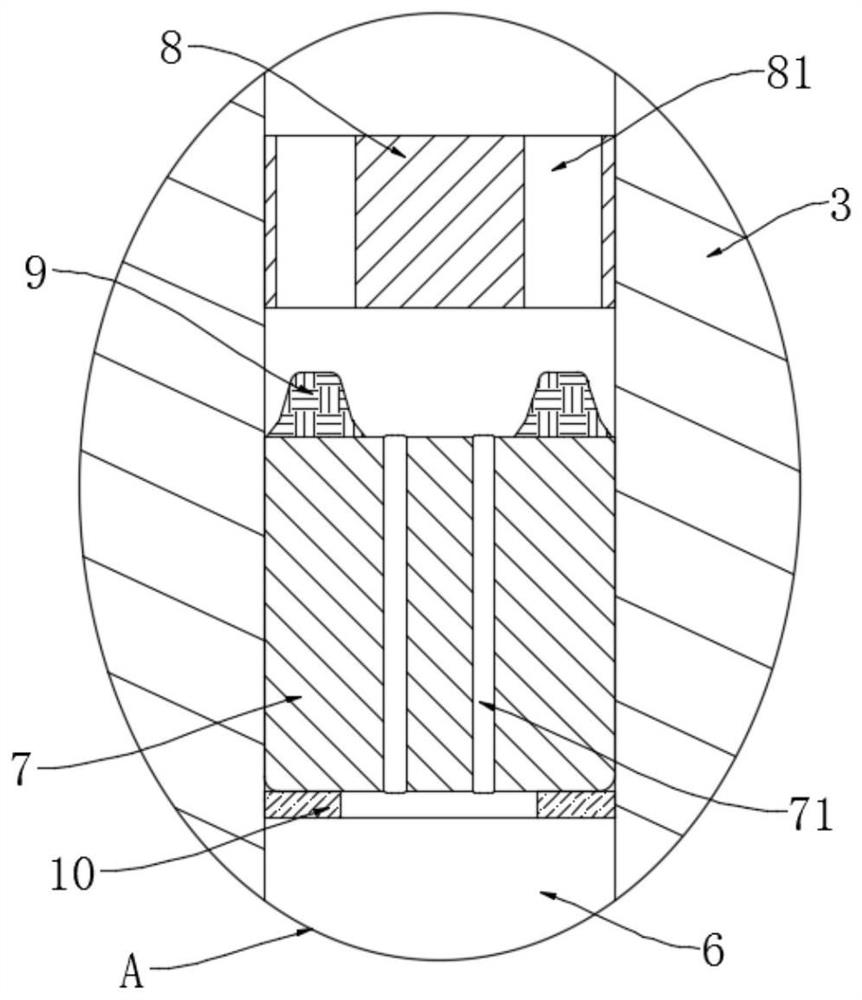

[0021] refer to Figure 1-2 , a self-venting type safety syringe, comprising a syringe 1 and a needle tube 2 fixedly connected to the syringe 1, a push rod 11 is placed inside the syringe 1, a fixing block 3 is provided at the lower end of the push rod 11, and the fixing block 3 A rubber stopper 4 is bonded to the inner wall of the syringe 1. The rubber stopper 4 acts as a seal. The bottom of the fixed block 3 is also provided with a guide plate 5. The edge of the guide plate 5 is tangent to the vertical groove 6, which can guide the gas. Flowing into the vertical groove 6, the fixed block 3 is provided with a plurality of vertical grooves 6, and a slider 7 is slidably installed in each vertical groove 6, and a plurality of first passages are symmetrically opened in the middle of each slider 7. Hole 71, the top of each slider 7 is symmetrically glued with a plurality of soft plugs 9, and each soft plug 9 does not overlap with the first through hole 71, and each vertical groove...

Embodiment 2

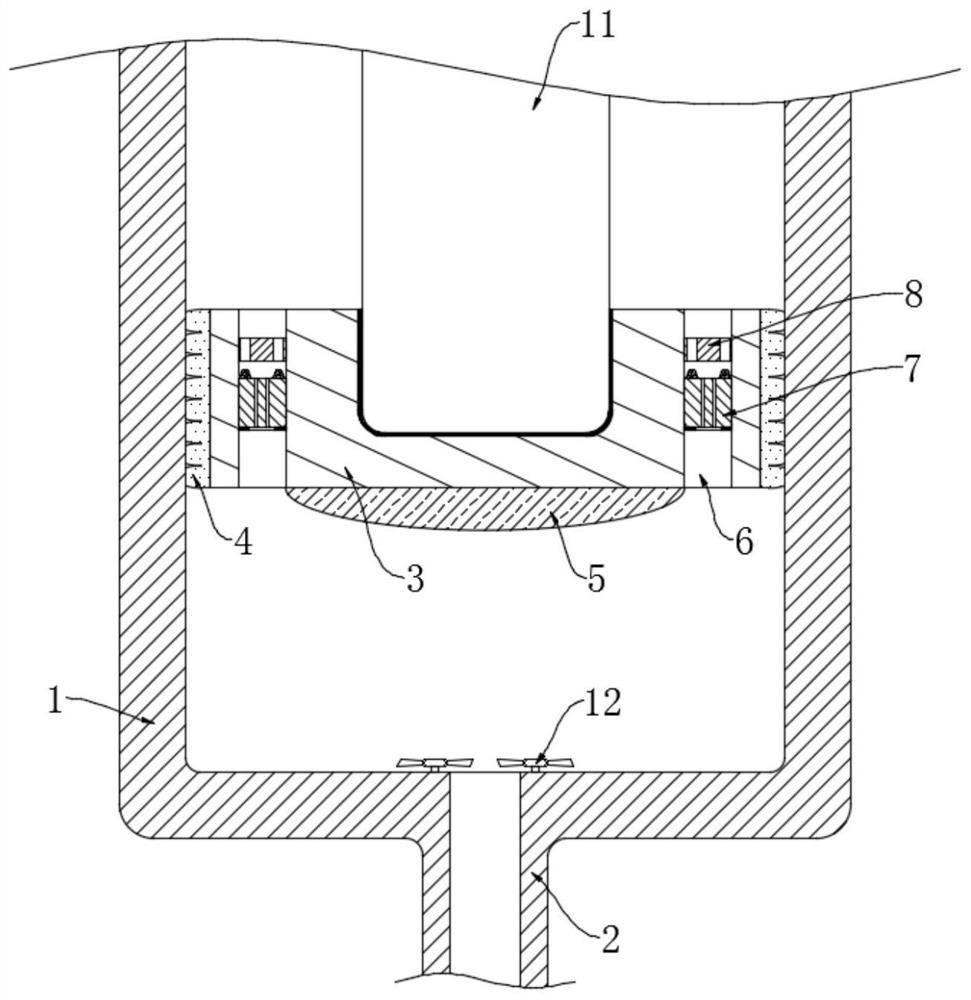

[0028] refer to Figure 3-4 The difference between this embodiment and Embodiment 1 is that: two turbulence fans 12 are symmetrically arranged at the connection between the needle tube 2 and the syringe 1, and each turbulence fan 12 includes a rotating shaft and a plurality of fan blades 121, and each Each fan blade 121 is made of elastic vibrating piece and is twisted. A plurality of needles 122 are distributed on the upper surface of each fan blade 121 . The needles 122 are close to the outside of the fan blade 121 .

[0029] This embodiment can illustrate its functional principle through the following operation mode: when the push rod 11 is pressed to make the liquid medicine flow to the needle tube 2, because the diameter difference between the needle tube 1 and the needle tube 2 is relatively large, the liquid medicine will enter the needle tube At 2 o'clock, there will be an obvious angle change, thereby promoting the fan blade 121 of the spoiler fan 12, causing the spoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com