Production device for pipe pile die assembly accessories

A production device and mold technology, which is applied in the production device field of pipe pile mold clamping parts, can solve the problems of unstable blanking, waste of resources, tapping, etc., and achieve the effect of ensuring stability and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

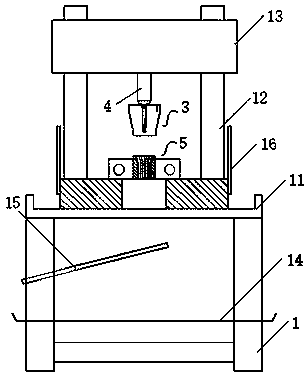

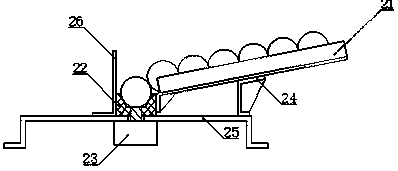

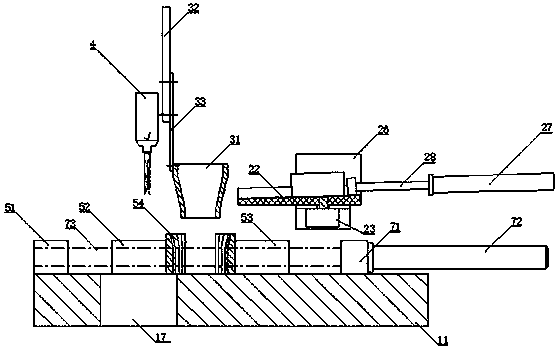

[0044] The production device of the pipe pile mold clamping accessories of this embodiment, such as Figure 1-Figure 7 As shown, it includes a frame 1 , a feeding assembly 2 , a blanking device 3 , a tapping device 4 , a clamping mechanism 5 for clamping or loosening workpieces, a differential assembly 6 and a horizontal driving mechanism 7 .

[0045] Such as figure 1 As shown, the upper end of the frame 1 is provided with a base 11, on both sides of the upper end of the base 11, a column 12 is provided, and the upper end of the column 12 is also provided with a crossbeam 13 fixedly connected with the column; The discharge support frame 14 that is fixedly connected to the frame 1, the base above the discharge support frame 14 is also provided with a discharge guide plate 15 that is inclined from the base 11 to the outer frame of the discharge support frame 14; in the implementation process, In order to effectively avoid the debris generated during the tapping process from spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com