Crop straw carbonizing equipment

A technology of crop straw and equipment, which is applied in the field of resource utilization of agricultural waste, can solve the problems of low resource utilization rate, achieve the effects of reducing heating costs, thoroughly crushing, and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

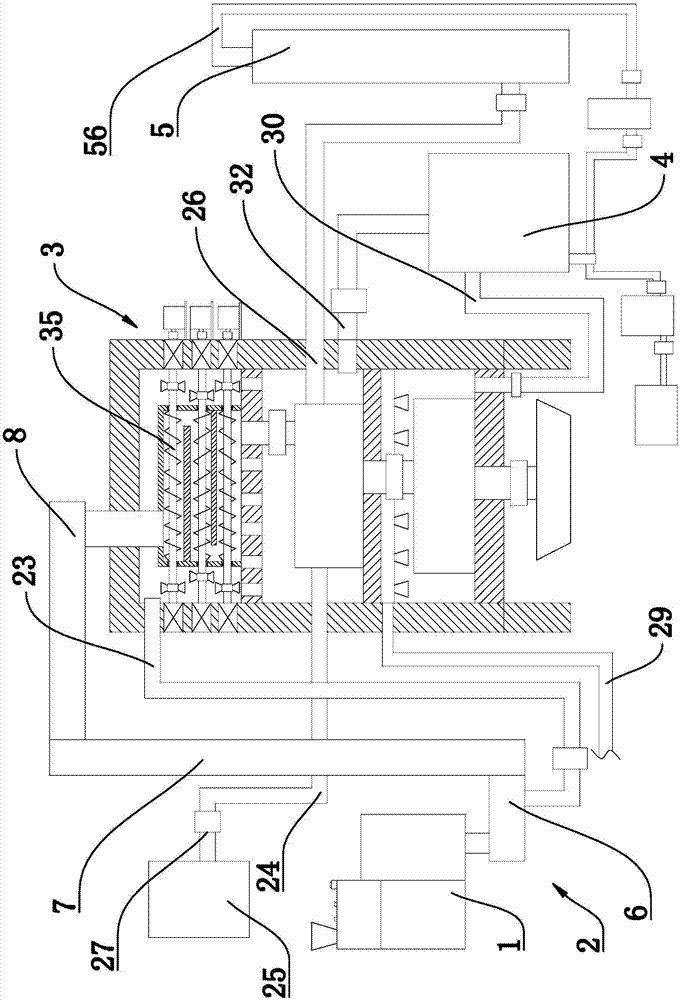

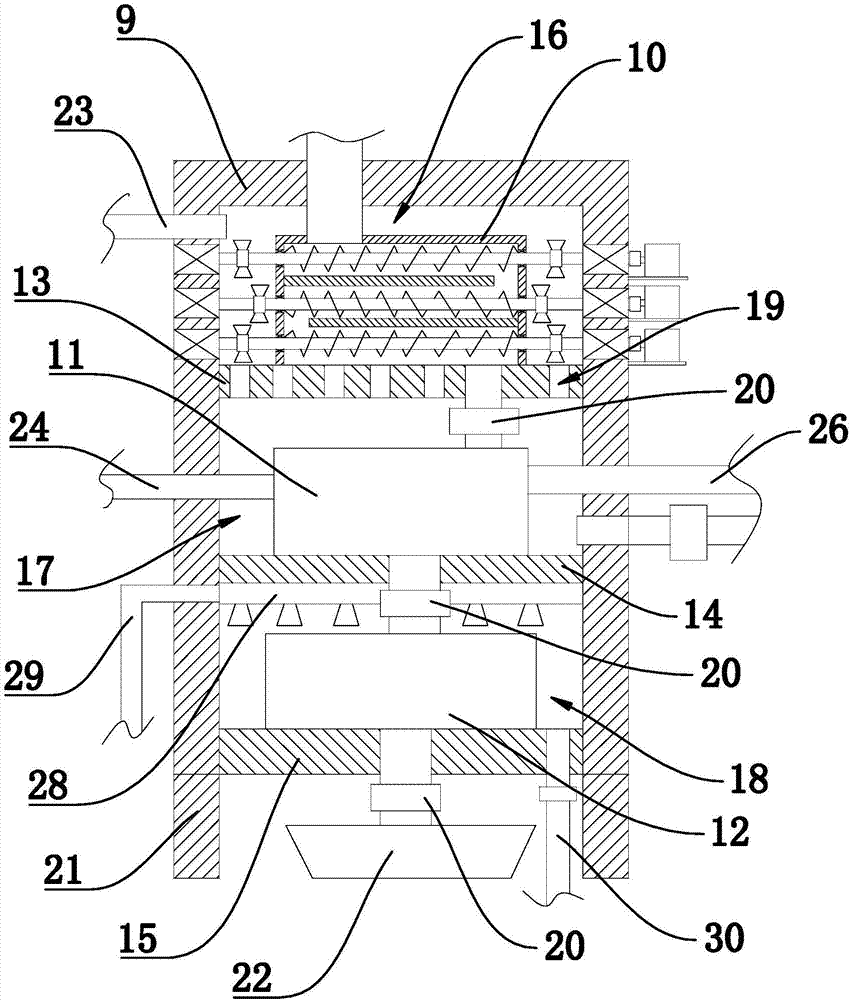

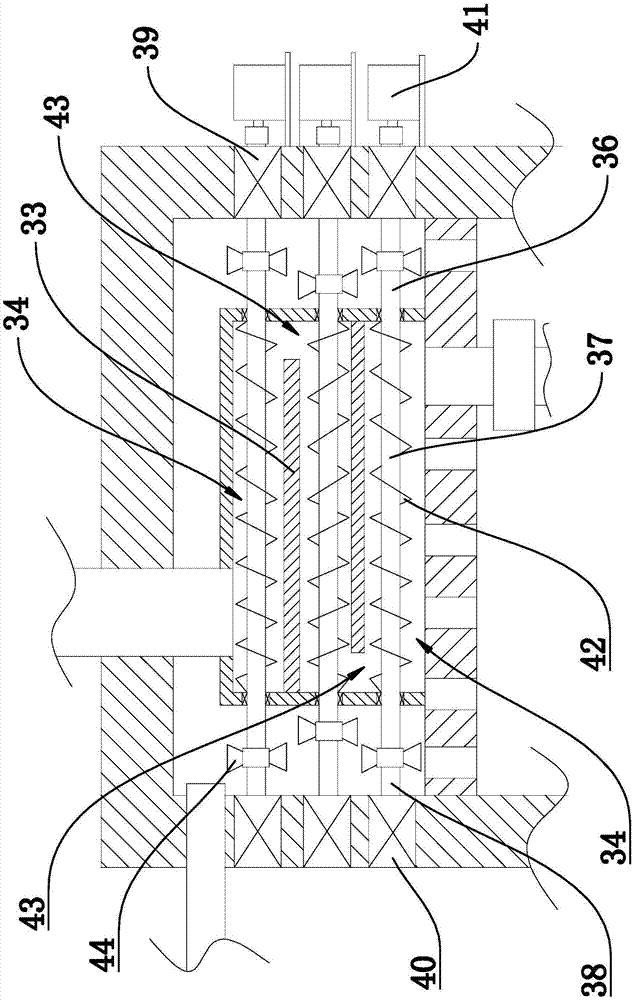

[0028] Such as Figure 1 to Figure 8As shown, the present invention provides a kind of crop straw charcoal production equipment, including straw pulverizer 1, feeding mechanism 2, charcoal furnace 3, heating furnace 4 and flue gas treatment tower 5; straw pulverizer 1 is connected by feeding mechanism 2 In the charcoal furnace 3, the harvested straw is first put into the straw crusher 1 for crushing, and the crushed straw is sent into the charcoal furnace 3 by the feeding mechanism 2 for carbonization, and the heating furnace 4 is connected to the charcoal furnace 3, The heating furnace 4 provides the heat required for carbonization of the straw, the charcoal furnace 3 communicates with the feeding mechanism 2, and the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com