Processing method for beveling of disc lens, and beveling processing device

A processing method and a technology of a processing device, which are applied in the field of chamfering of disc-shaped lenses, can solve the problems of being unable to adapt to the chamfering of disc-shaped lenses, and achieve the effects of uniform chamfering, high efficiency, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

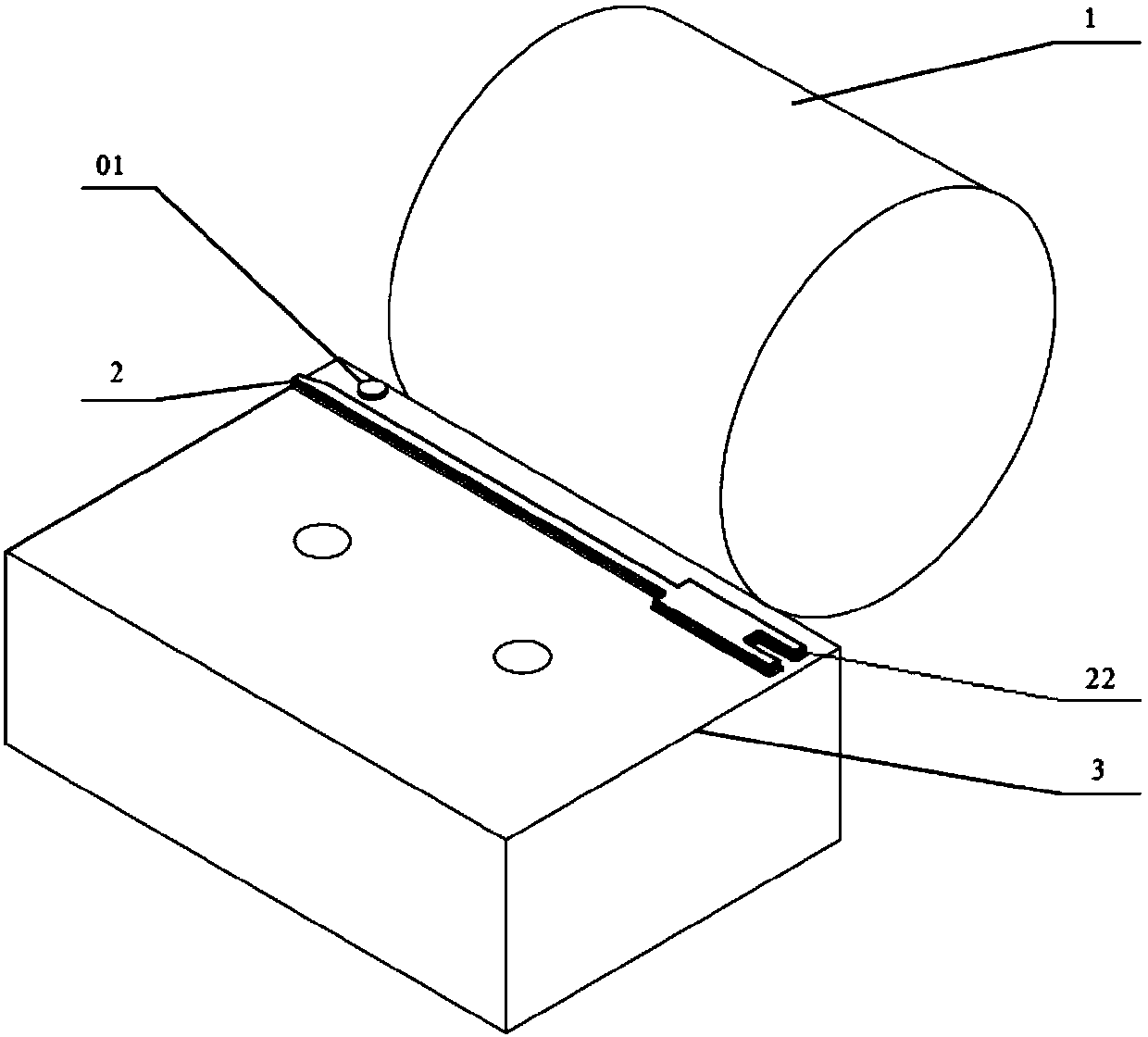

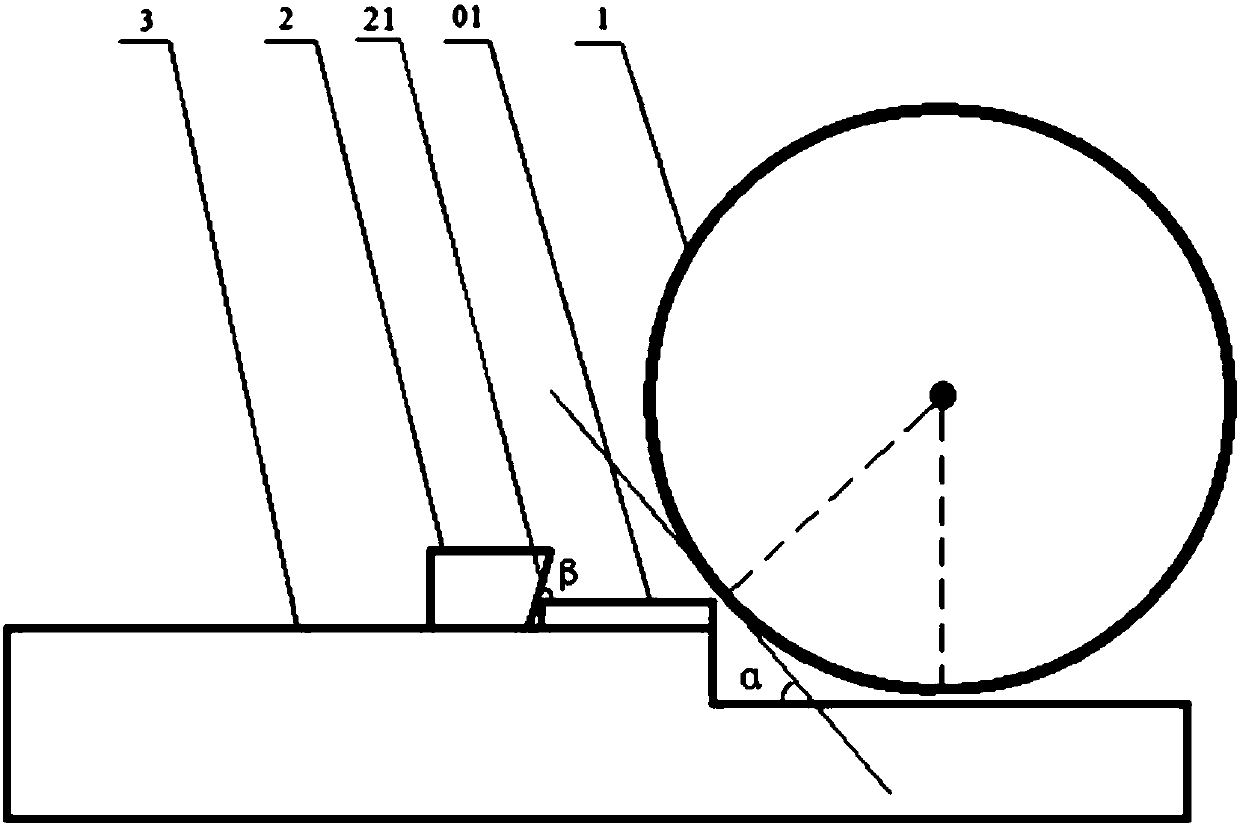

[0021] Specifically, the sapphire camera lens to be chamfered in the present invention is a small disc with a diameter of 3mm and a thickness of 0.5mm, and its straight body needs to be chamfered by 0.05-0.15mm to ensure that the product is smooth and natural. The present invention adopts following technical scheme to realize, comprises the steps:

[0022] The first step is to prepare the machine. The length of the beveling grinding wheel is designed to be 50mm and the diameter is 50mm. The beveling grinding wheel is coated with 800# diamond grit, and the grinding wheel is installed on the small milling bed machine. The machine model is X1514B.

[0023] The second step is to prepare the base and design a cuboid iron block with the dimensions: 70mm in length, 50mm in width, and 30mm in height, and fix it under the grinding wheel with screws. When fixing, the length direction of the iron block is 70mm in the same direction as the length direction of the grinding wheel. Leave two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com