Automatic synchronization net puller and net pulling method

A technology of automatic synchronization and drawing machine, applied in the field of drawing screen of screen printing, can solve the problems of unqualified mesh, waste of mesh, waste of four corners, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

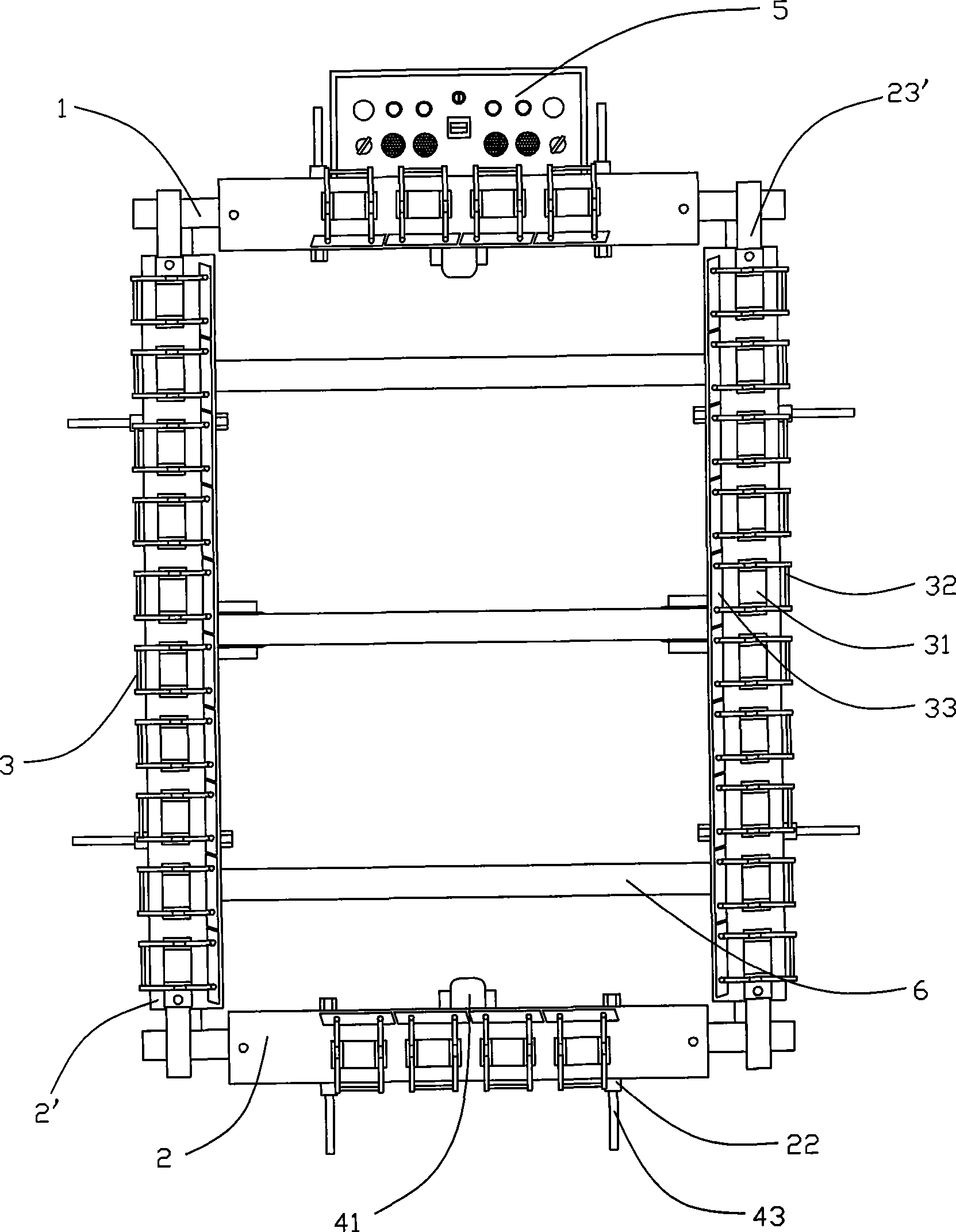

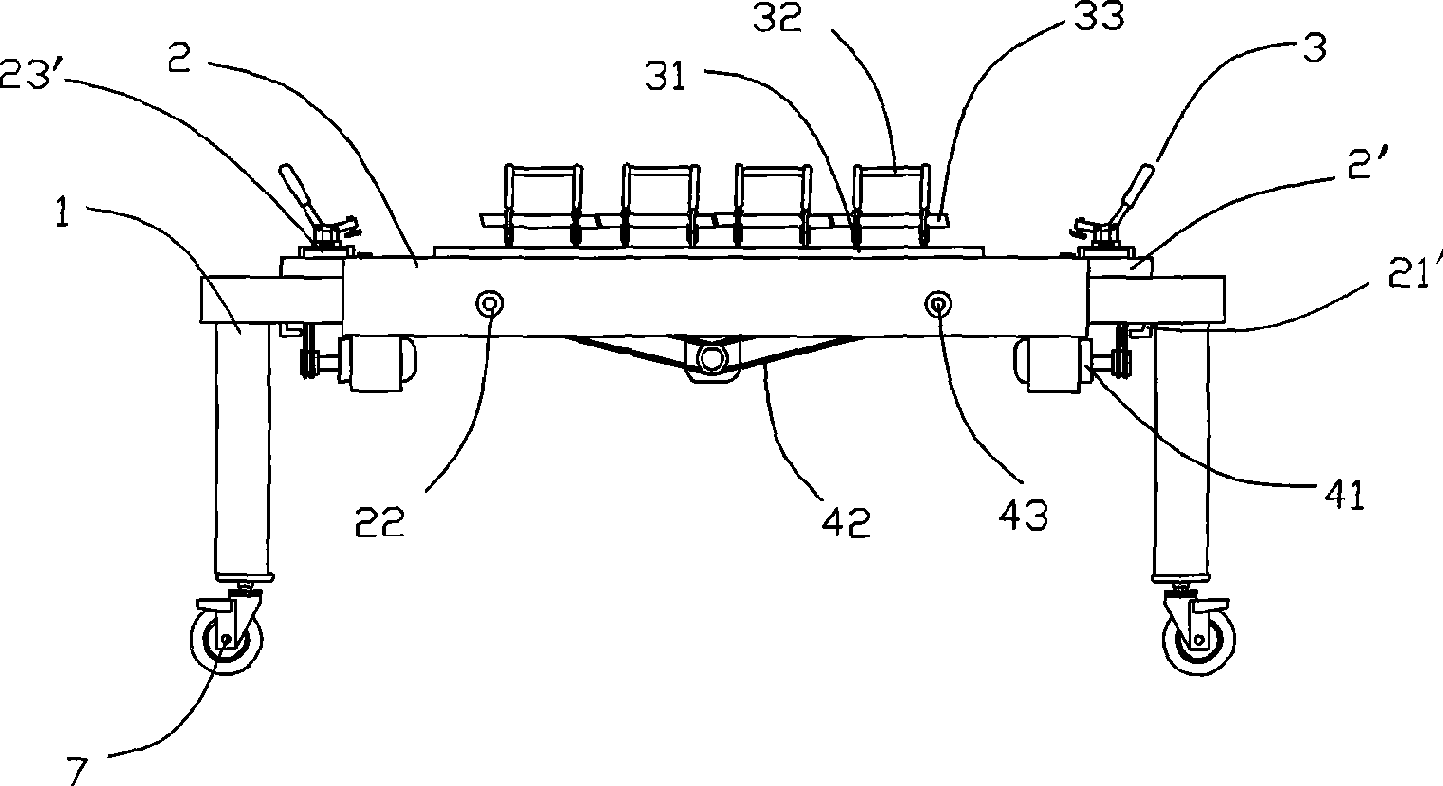

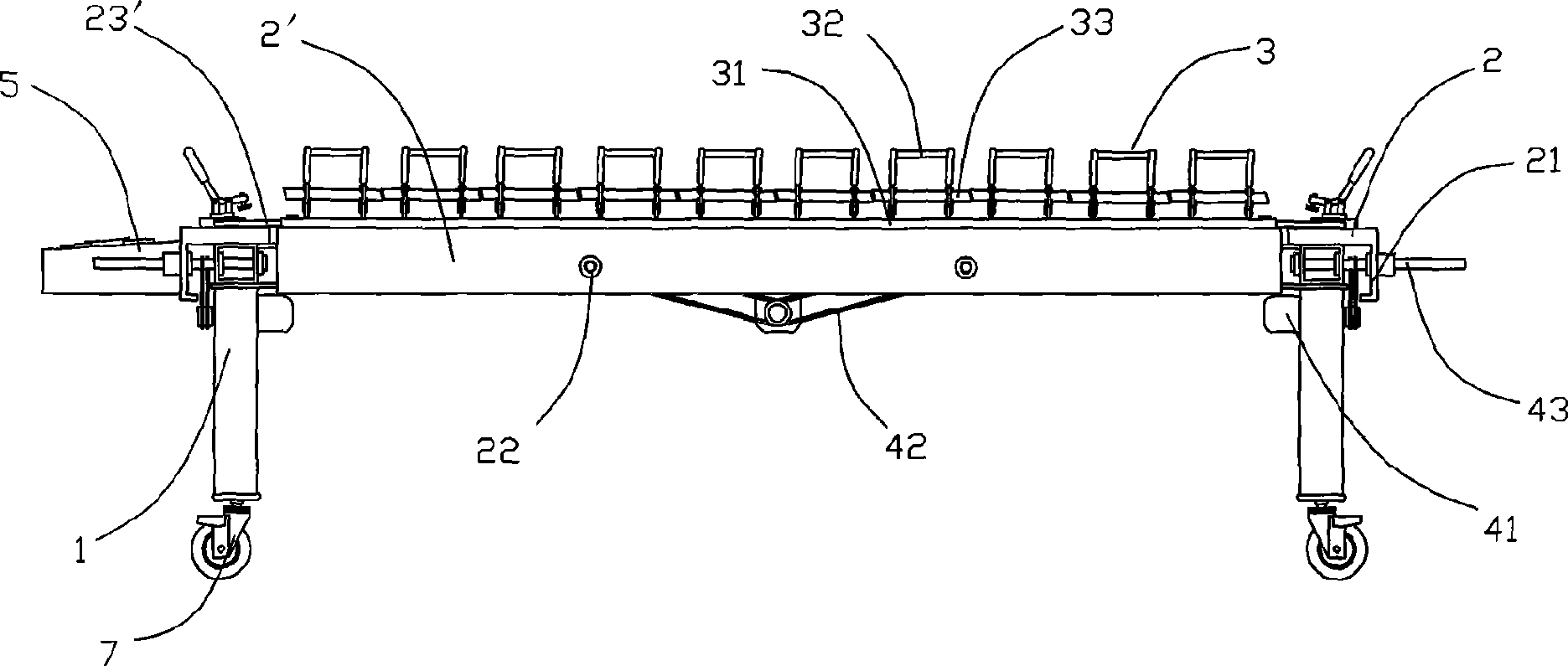

[0027] refer to Figure 1 ~ Figure 3 , the automatic synchronous stretching machine of the present invention comprises a frame 1, a warp screw displacement mechanism 2 erected on the body 1, a weft screw displacement mechanism 2′, and a warp screw displacement mechanism 2 and a weft screw installed on the machine body 1. The stretching chuck 3 on the displacement mechanism 2', the warp thread screw displacement mechanism 2 or the weft thread screw displacement mechanism 2' each have two, respectively symmetrically installed on the opposite sides around the frame 1, on the frame 1 There are two groups of synchronous motor groups installed on the top, and each group of synchronous motor groups is respectively connected to the warp thread screw displacement mechanism 2 or the weft thread screw displacement mechanism 2' on this side, and controls the warp thread screw displacement mechanism 2 or the weft thread screw displacement mechanism on this side. 2' is displaced inwardly or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com