Bolt combination installation device and application method

A technology combining installation and application methods, applied in the field of building decoration materials, can solve the problems of difficulty in distinguishing the direction of the bolt head, unfavorable construction operations, uneven force on the screw, and achieve the effects of increasing convenience, flexibility and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

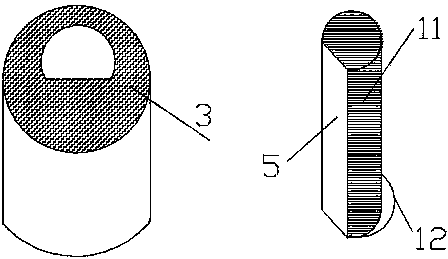

[0046] refer to figure 2 and Figure 6 , a bolt combination installation device, including a screw 1 and a nut 2, the screw 1 is composed of a rod body 11 and a countersunk head 12, the rod body 11 is a threaded rod body with a plane section 5, and the bolt combination installation device also It includes a positioning piece 3 used in conjunction with the rod body 11. The horizontal section of the positioning piece 3 is a circular cylinder, and the countersunk head 12 is all protruding from the outside of the combined body formed by the combination of the rod body 11 and the positioning piece.

[0047] The installation steps of the bolt combination installation device are as follows:

[0048] 1) On the wall 100, a slot 7 matching the shape of the combined body formed by the combination of the rod body 11 and the positioning piece 3 is provided, and a hooking slot 8 matching the countersunk head 12 is provided at the bottom of the slot 7;

[0049] 2) Insert one end of the co...

Embodiment 2

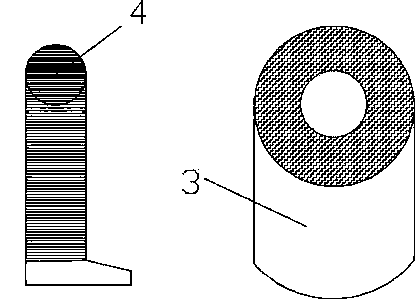

[0055] refer to figure 1 , Figure 5 and Figure 8 , a bolt combination installation device, comprising a screw 1 and a nut 2, the screw 1 is composed of a rod body 11 and a countersunk head 12, the rod body 11 is a cylindrical threaded rod body 4, and one end of the rod body 11 away from the countersunk head 12 is provided There is a groove 41, and the bolt combination installation device also includes a positioning piece 3 used in conjunction with the rod body 11. The horizontal section of the positioning piece 3 is a circular cylinder, and the countersunk head 12 is all protruded on the rod body 11 and the positioning The outside of the combined body formed by the combination of parts.

[0056] The application method of the bolt combination installation device comprises the following steps:

[0057] 1) On the veneer 200, a slot hole 7 matching the shape of the combined body formed by the combination of the rod body 11 and the positioning piece 3 is provided, and a hookin...

Embodiment 3

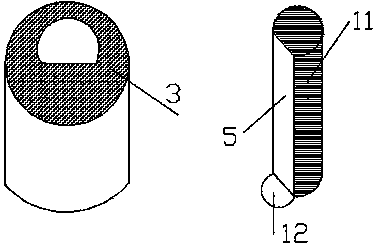

[0064] refer to figure 2 and Figure 7 , a bolt combination installation device, including a screw 1 and a nut 2, the screw 1 is composed of a rod body 11 and a countersunk head 12, the rod body 11 is a threaded rod body with a plane section 5, and the rod body 11 is far away from the countersunk head One end of 12 is provided with a metal strip 42. The bolt combination installation device also includes a positioning piece 3 used in conjunction with the rod body 11. The horizontal section of the positioning piece 3 is a circular cylinder, and the countersunk heads 12 are all protruded on the The outer surface of the combined body formed by combining the rod body 11 and the positioning member.

[0065] The installation steps of the bolt combination installation device are as follows:

[0066] 1) On the veneer 200, a slot hole 7 matching the shape of the combined body formed by the combination of the rod body 11 and the positioning piece 3 is provided, and a hooking slot 8 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com