Amino/mercapto silane modified silica and preparation method thereof

A technology of mercaptosilane and silica, which is applied in the field of silica materials for the rubber industry, can solve the problems of reducing the surface reactivity of coupling agents and white carbon black powders, affecting the processing performance of rubber materials, etc., and achieving the reduction of hydrophilicity Sex, inhibition of agglomeration and secondary agglomeration, post-treatment pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

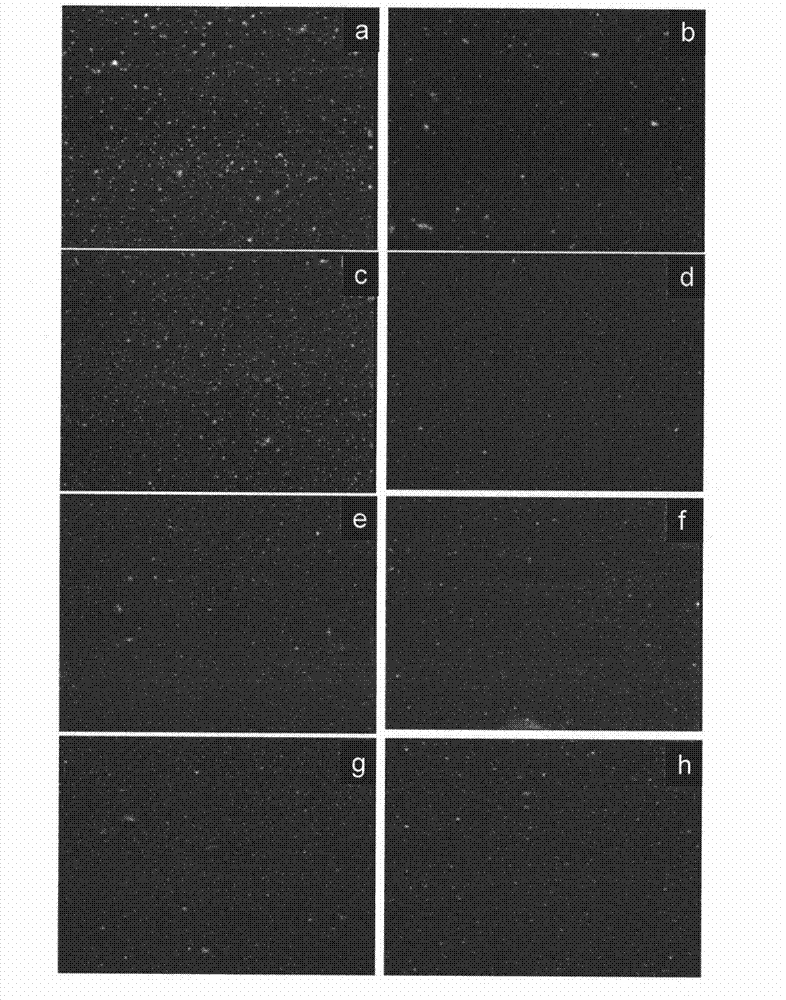

Image

Examples

Embodiment 1

[0026] A. Weigh 21.3g Na 2 SiO 3 9H 2 O, dissolved in 50mL deionized water to prepare an aqueous solution with a concentration of 1.5M, heated to dissolve; 7.5g of concentrated sulfuric acid was slowly added to water, and diluted to a concentration of 5M sulfuric acid solution 15mL;

[0027] B. When the temperature of the sodium silicate solution reaches 25°C, start to add the sulfuric acid solution dropwise while stirring, and the sulfuric acid solution dropping rate is 0.1mL / min;

[0028] C. when the pH value of reaction solution was about 2, stop dripping sulfuric acid solution;

[0029] D. adjust the pH value to 7 with a concentration of ammonia solution of 7.5M;

[0030] E. After filtering and cleaning the material liquid obtained in step D, disperse the silica with ethanol, quickly add 0.75g γ-aminopropyltriethoxysilane, and then add 1.5g γ-mercaptopropyltriethoxy Silane;

[0031] F. After stirring and reacting for 1 hour at room temperature, remove ethanol by filtr...

Embodiment 2

[0033] A. Weigh 22.7g Na 2 SiO 3 9H 2 O, dissolved in 100mL deionized water to prepare an aqueous solution with a concentration of 0.8M, heated to dissolve; take 8g of concentrated sulfuric acid and slowly add it to water, and dilute to 80mL of a 1M sulfuric acid solution;

[0034] B. When the temperature of the sodium silicate solution reaches 30°C, start to drop the sulfuric acid solution while stirring, and the sulfuric acid solution dropping rate is 1.5mL / min;

[0035] C. when the pH value of reaction solution was about 2, stop dripping sulfuric acid solution;

[0036] D. adjust the pH value to 7 with a concentration of 5M ammonia solution;

[0037] E. After filtering and cleaning the material liquid obtained in step D, disperse silicon dioxide with ethanol, quickly add 0.4g N-β(aminoethyl)-γ-aminopropyltriethoxysilane, and then add 2.0 g2-mercaptoethyltriethoxysilane;

[0038] F. After stirring and reacting for 1 hour at room temperature, remove ethanol by filtration...

Embodiment 3

[0040] A. Weigh 28.4g Na 2 SiO 3 9H 2 O, dissolved in 100mL deionized water to prepare an aqueous solution with a concentration of 1.0M, heated to dissolve; take 10g of concentrated sulfuric acid and slowly add it to water, and dilute to 100mL of a sulfuric acid solution with a concentration of 0.5M;

[0041] B. When the temperature of the sodium silicate solution reaches 40°C, start to add the sulfuric acid solution dropwise while stirring, and the sulfuric acid solution dropping rate is 2.0mL / min;

[0042] C. when the pH value of reaction solution was about 2, stop dripping sulfuric acid solution;

[0043] D. adjust the pH value to 8 with a concentration of 10M ammonia solution;

[0044] E. After filtering and cleaning the material liquid obtained in step D, disperse the silica with deionized water, quickly add 1.5g γ-aminopropyltrimethoxysilane, and then add 0.6g γ-mercaptopropyltrimethoxy base silane;

[0045] F. After stirring and reacting for 1 hour at room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com