Air compressor oil composition and preparing method thereof

An air compressor oil and composition technology, applied in the field of lubricating oil, can solve the problems of affecting oxidation stability and corrosion, adverse environmental protection, etc., to avoid oil change and equipment failure maintenance, improve boundary lubricity and anti-wear ability, the effect of increasing wear resistance and lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

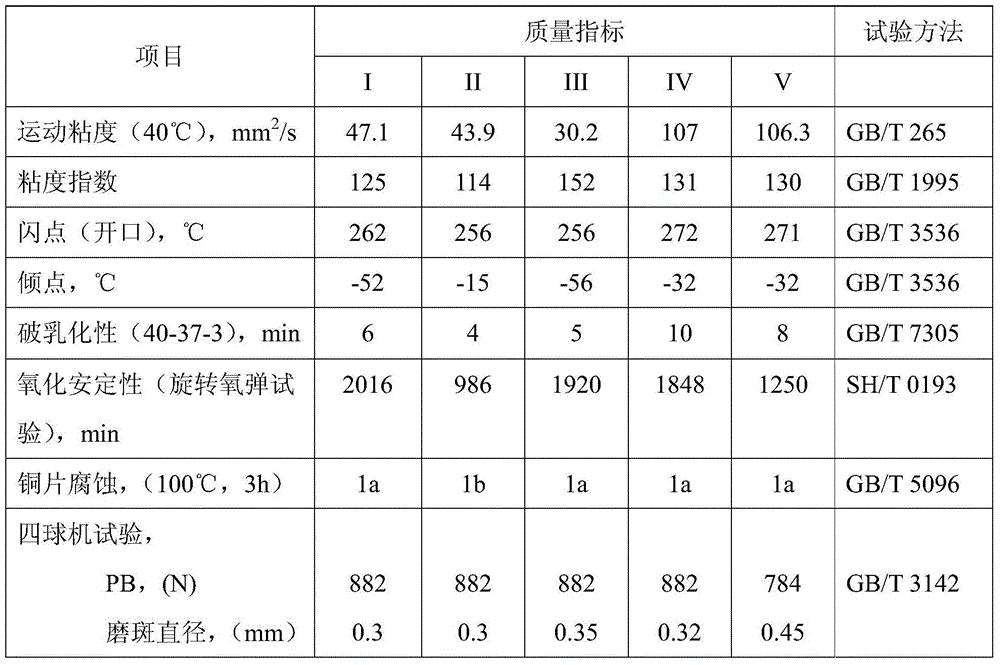

Examples

Embodiment 1

[0042] Take 60g of trimellitate Emkarate1942 respectively (the kinematic viscosity at 40℃ is 71mm 2 / s, test standard GB / T265, the same below) (Croda Chemical Company) and 40g of polyα-olefin base oil Synbase Polyolefin6 (Exxonmobil Companies, the same below) were put into a 200ml beaker, and then 0.5g of liquid octylbutyl was added in turn Diphenylamine antioxidant Irganox L57 (Basf Chemical Company, the same below), 0.5 g methylene bis-dibutyl dithiocarbamate Vanlube7723 (R.T. Vanderbilt Company, Inc., the same below), 0.5 g oily agent Benzyltriazole octadecylamine salt compound T406 (Shenyang Hualun Oil Chemical Co., Ltd., the same below), 1.0g high-viscosity complex ester compound Priolube3986 (kinematic viscosity at 40°C is 47000mm 2 / s) (Croda Chemical Company, the same below), 0.1 g of benzotriazole derivatives T551 (Jinzhou Kangtai Lubricating Oil Additives Co., Ltd., the same below), 0.003 g of methyl silicone oil T901 (Jinzhou Kangtai Lubricating Oil Additives Co., L...

Embodiment 2

[0046] Take 51g of adipic acid diester HATCOL2901 (kinematic viscosity of 28mm at 40°C) 2 / s) (Chemtura Corporation) and 49g of polyα-olefin base oil Synbase Polyolefin6 were put into a 200ml beaker, and then 0.3g of octylbutyldiphenylamine antioxidant Irganox L57, 1.0g of dibutyldithioamino were added in turn Formate Octopol MB (TIARCO Chemical Company, the same below), 0.8g oily agent benzotriazole fatty amine salt compound T406, 0.4g high viscosity complex ester compound Priolube3986, 0.06g thiadiazole derivative T561 (Jinzhou Kangtai Lubricating Oil Additives Co., Ltd.), 0.005g of methyl silicone oil T901, 0.002g of propylene oxide-ethylene oxide block copolymer demulsifier LZ5957, stirred at 50 ° C until uniform and transparent, to obtain an environmentally friendly, energy-saving and long-life air compressor Oil Composition III.

Embodiment 3

[0048] Take 75g of saturated polyol ester Priolube3987 (kinematic viscosity at 40℃ is 145mm 2 / s) (Croda Chemical Company, the same below), 15g saturated polyol ester Priolube3970 (kinematic viscosity at 40°C is 20mm 2 / s) (Croda Chemical Company, the same below) and 10g of polyα-olefin base oil Synbase Polyolefin6 were put into a 200ml beaker, and then 0.8g of p-,p-'dioctyldiphenylamine antioxidant Vanlube81 (R.T.Vanderbilt Holding Company, Inc, the same below), 0.5g dibutyldithiocarbamate Octopol MB, 0.3g oily agent benzotriazole fatty amine salt compound T406, 1.5g high viscosity complex ester compound Priolube3986, 0.1g benzene Triazole derivatives T551, 0.005g methyl silicone oil T901, 0.002g propylene oxide-ethylene oxide block copolymer demulsifier LZ5957, stirred at 50 ° C until uniform and transparent, to obtain an environmentally friendly, energy-saving and long-life air compressor Oil Composition IV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com