Patents

Literature

31results about How to "Good oxidation and corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of abrasion-proof and corrosion-resistant nickel-based alloy wire

The invention discloses an abrasion-proof and corrosion-resistant nickel-based alloy wire and a preparation method thereof. The alloy wire comprises the following components: 17-21% of C, 20-25% of Co, 1.8-2.2% of W, 6.4-9.5% of Mo, 1.4-1.8% of Al, 3.2-4.5% of Ti, 0.1-0.5% of Nb, 0.1-0.5% of Hf, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr, 0.005-0.008% of Mg, and the balance Ni. The preparation technology of the alloy comprises the steps of vacuum smelting, remelting, forging, hot rolling, drawing, solid solution treatment and aging treatment, namely, raw materials are prepared and smelted based on mass percent and then smelted; the smelted materials are forged and rolled into obtain alloyed wire rods; the alloyed wire rods are drawn at a plurality of times to obtain phi 0.05-0.4mm alloy wires; finally the alloy wires are subjected to solid solution treatment and aging treatment. The abrasion-proof and corrosion-resistant nickel-based alloy wire can be used as a brush wire material for brush sealing of an aircraft engine, a gas turbine, etc., thus the brush sealing effect can be effectively improved, and the service life can be prolonged.

Owner:江苏鑫信润科技股份有限公司

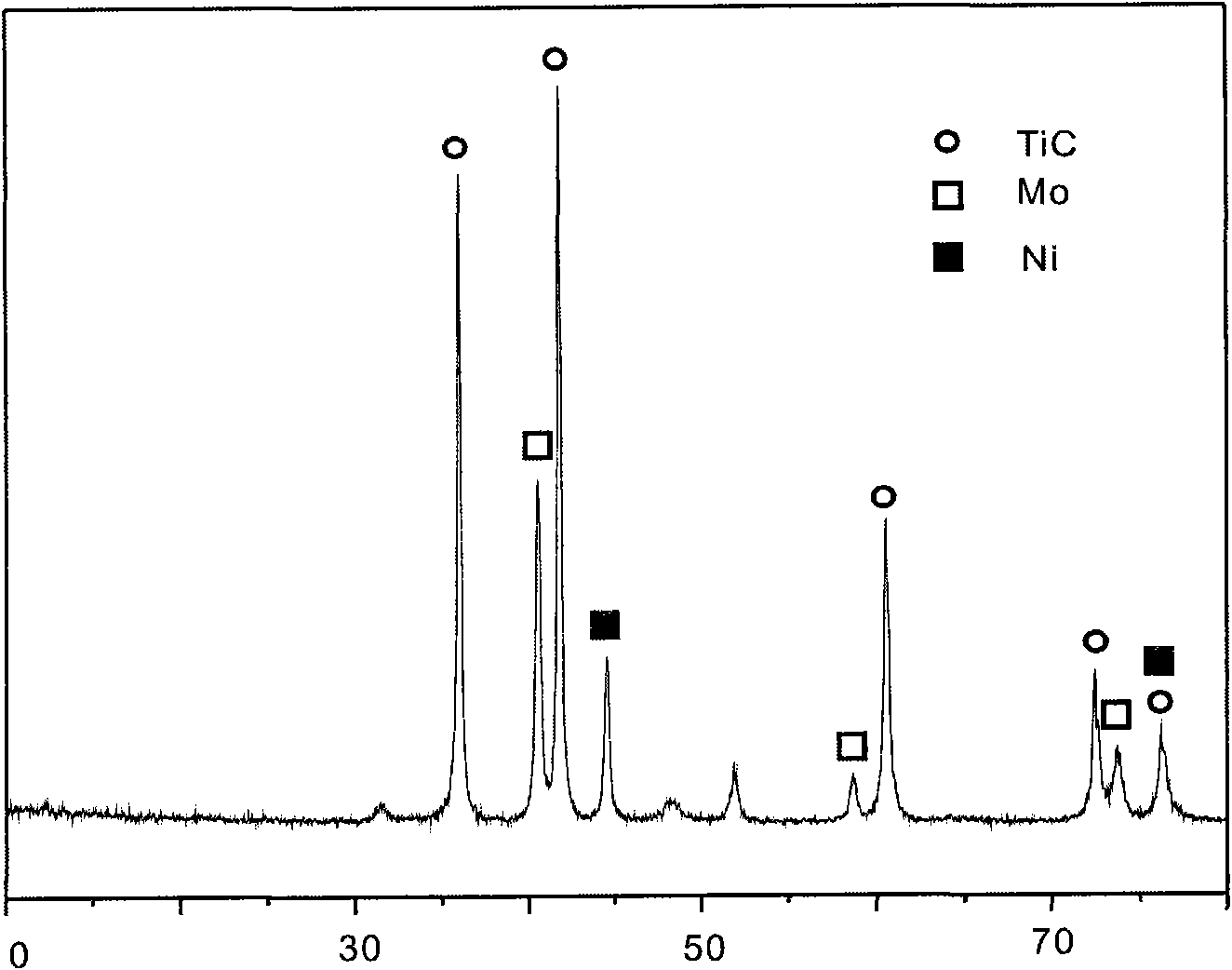

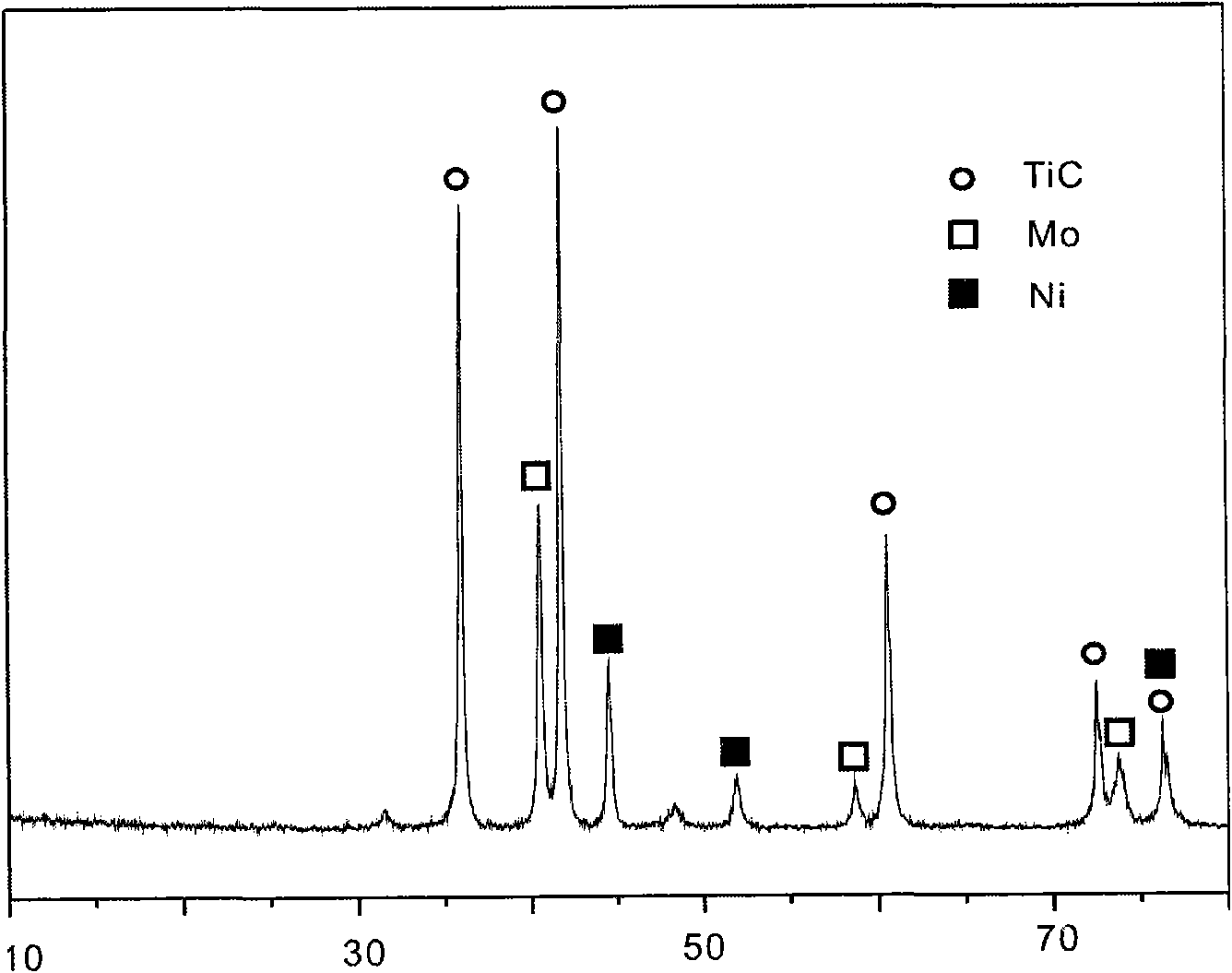

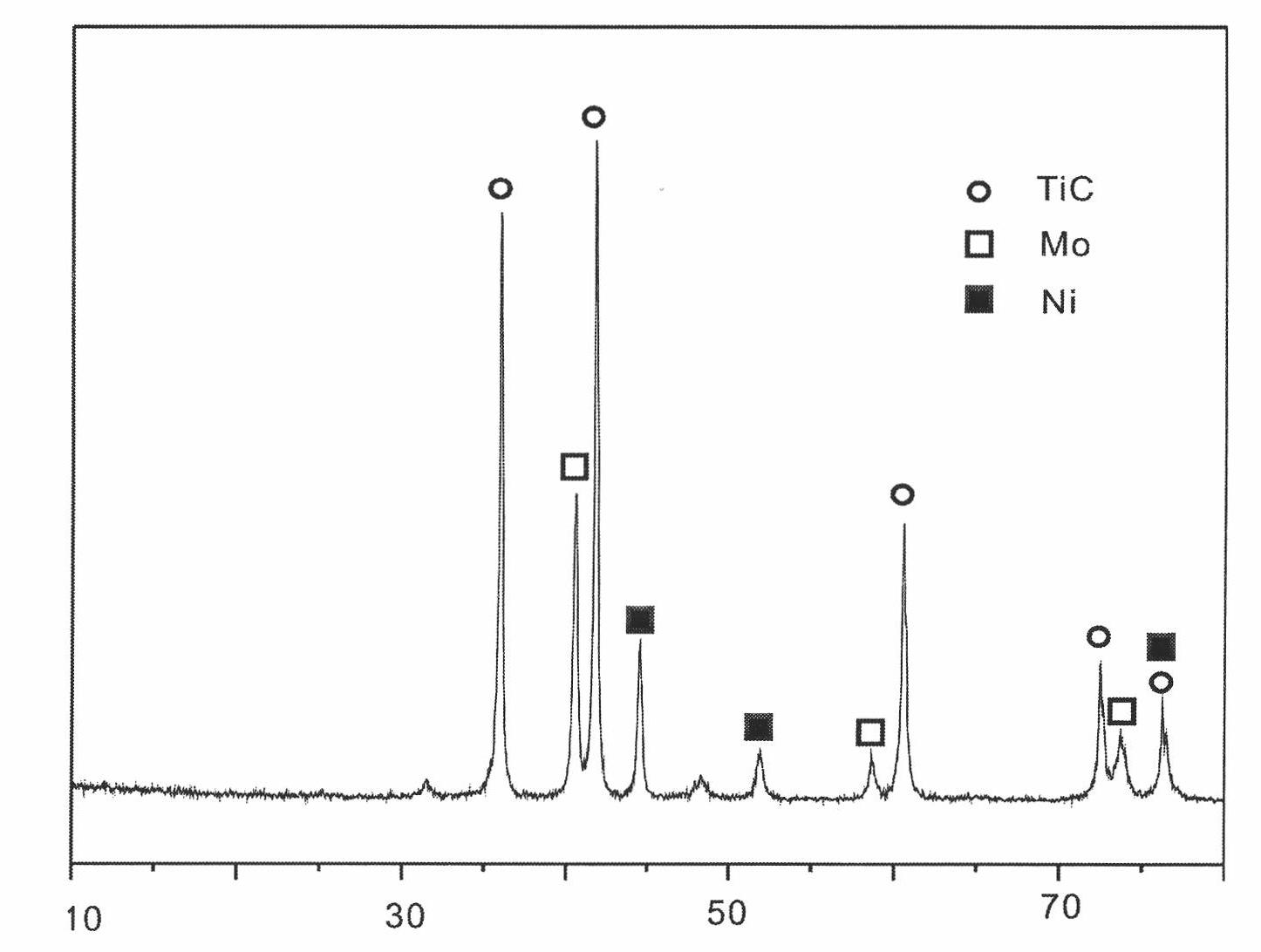

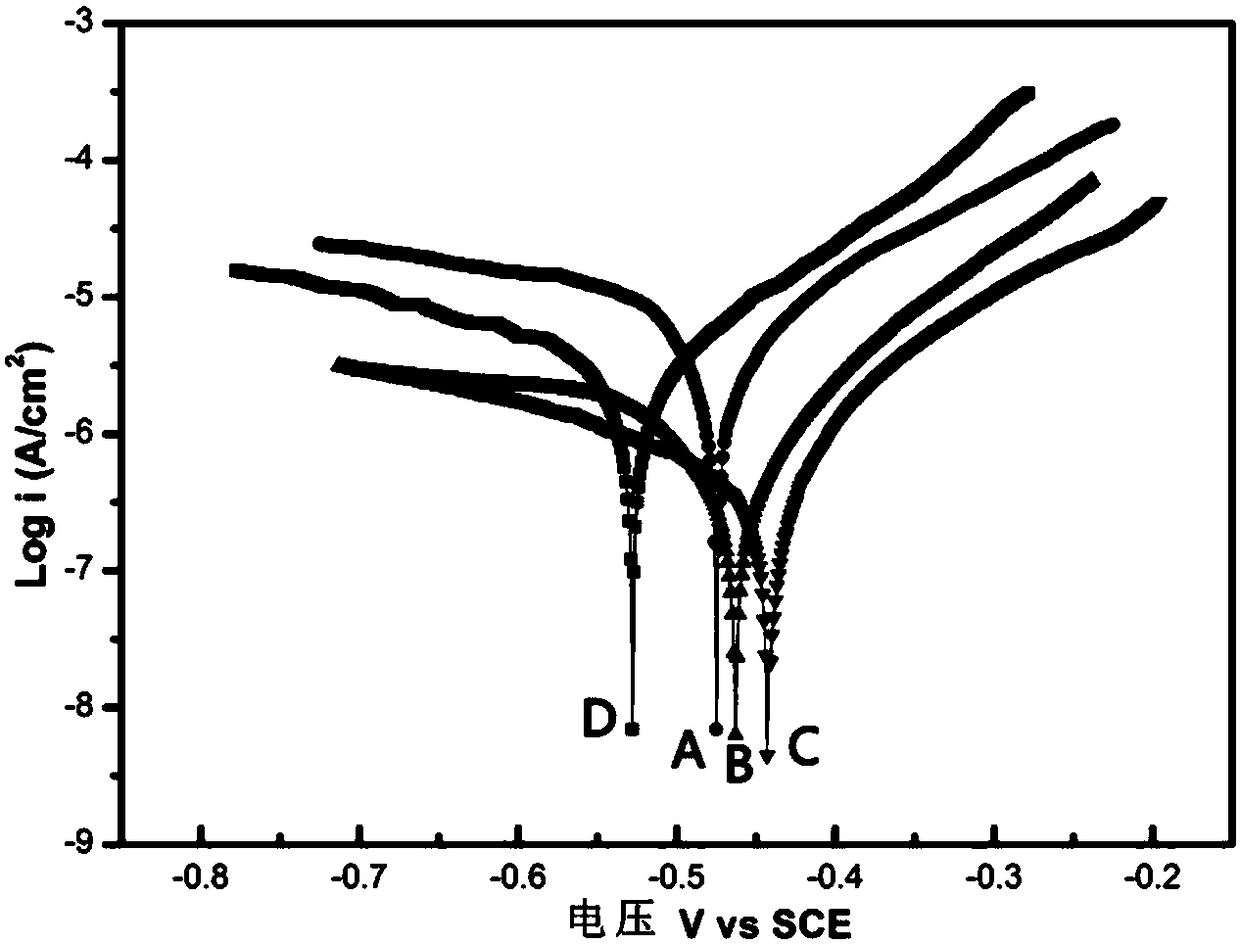

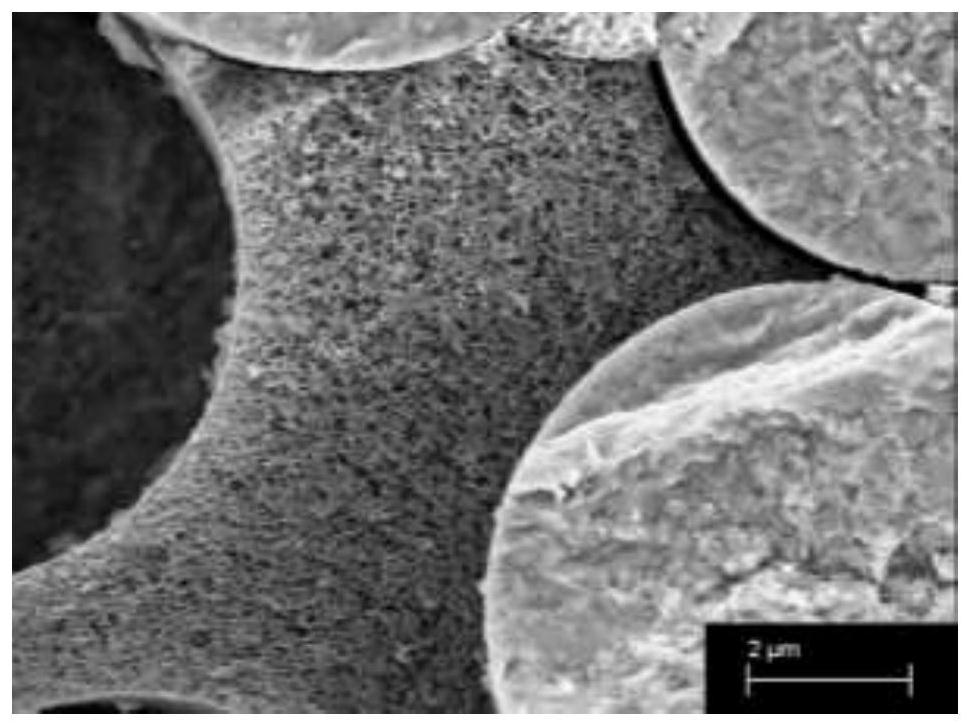

Titanium carbide-based hard alloy taking nickel-molybdenum alloy as adhesive and preparation method thereof

InactiveCN101967594AGood oxidation and corrosion resistanceImprove wettabilityCemented carbideParaffin wax

The invention discloses a titanium carbide-based hard alloy taking a nickel-molybdenum alloy as an adhesive and a preparation method thereof. The titanium carbide-based hard alloy consists of the following raw materials in percentage by mass: 13 to 20 percent of nickel powder, 7 to 10 percent of molybdenum powder and the balance of titanium carbide powder. The preparation method comprises the following steps of: adding the nickel powder, the molybdenum powder and the titanium carbide powder into a ball mill for wet milling, filtering and drying; adding paraffin wax; uniformly mixing, drying and performing compression molding; putting the mixture into a hydrogen atmosphere after molding and preserving heat at the temperature of between 300 and 500 DEG C for 2 to 3 hours; and sintering the mixture under the vacuum degree of 1*10<-2> to 5*10<-2> Pa at the temperature of between 1,400 and 1,450 DEG C so as to obtain a finished product. An alloy material prepared by the method has high hardness, high wear resistance, high corrosion resistance, low consumption of strategic resources, low porosity and high performance price ratio, can be applied to (half) finish machining of low carbon steel continuous cutting and can be taken as a substrate material for a diamond coating cutter.

Owner:HEFEI UNIV OF TECH

Rose gold plating layer and preparation method therefor

InactiveCN105313398AGuaranteed appearance qualitySmall color differenceVacuum evaporation coatingSputtering coatingTitanium nitrideTitanium carbonitride

The invention provides a rose gold plating layer for overcoming the problem that in the prior art, after surface abrasion, the rose gold clad layer is relatively great in chromatic aberration and low in appearance quality. The rose gold plating layer comprises a titanium carbonitride layer and a copper-gold alloy layer positioned on the surface of the titanium carbonitride layer, wherein the chroma system coordinate LAB values of the carbon titanium nitride layer are as follows: the L value is 68-70, the A value is 9-12 and the B value is 15-18; the chroma system coordinate LAB values of the copper-gold alloy layer are as follows: the L value is 84-87, the A value is 9-12, and the B value is 15-18. Meanwhile, the invention further discloses a preparation method for the rose gold plating layer. The chromatic aberration of the titanium carbonitride layer and the copper-gold alloy layer of the rose gold plating layer is small. Even if the copper-gold alloy layer on the surface is abraded, the appearance quality of the rose gold plating layer is not obviously affected.

Owner:SHENZHEN SENTAI METAL TECH CO LTD

Preparation method of high-strength melt-down non-woven fabric

InactiveCN107938176ASimple processIncrease productivityNon-woven fabricsSodium Molybdate DihydrateWoven fabric

The invention discloses a preparation method of a high-strength melt-down non-woven fabric. The preparation method of the high-strength melt-down non-woven fabric comprises the following operating steps of (1) uniformly mixing and feeding polybutylene terephthalate, polycarprolactam, sodium molybdate dehydrate, N-octyl diaminoethyl glycine hydrochloride and titanium isopropoxide tristearate into ascrew extruder for melt extrusion to obtain functional masterbatch; (2) melt-down-spinning the functional masterbatch obtained in the step (1) through the screw extruder to obtain the non-woven fabric, wherein, during melt-down spinning, the air pressure is 0.3-0.5 MPa, the receiving distance is 11-15 cm, and the rotating speed of a measuring pump is 66-75 Hz. According to the technical scheme, the preparation method of the high-strength melt-down non-woven fabric is simple and stable in process and high in production efficiency; the prepared high-strength melt-down non-woven fabric is excellent in anti-corrosion and antioxidant property, and particularly high in mechanical property and strength.

Owner:MAANSHAN CITY XIN CHENG NANO NEW MATERIAL TECH CO LTD

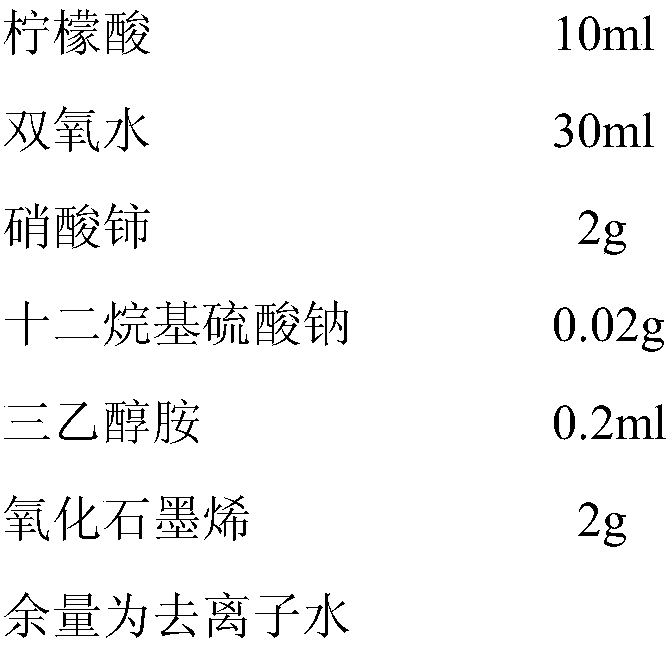

GO-doped environment-friendly passivator, and preparation method and application thereof

The invention disclosed a GO-doped environment-friendly passivator, and a preparation method and application of the GO-doped environment-friendly passivator. The GO-doped environment-friendly passivator per liter comprises 10-80 ml of citric acid, 20-80 ml of hydrogen peroxide, 2-5 g of cerous nitrate, 0.01-0.1 g of lauryl sodium sulfate, 0.1-0.5 ml of triethanolamine, 1-5 g of graphene oxide, andthe balance deionized water. The environment-friendly passivator does not contain chromic acid. A passive film with good corrosion resistance, oxidation resistance and stability can be formed on thestainless steel surface by adding a stainless steel workpiece into the passivator of 50-70 DEG C for passivating treatment for 20-50 minutes.

Owner:SHANGHAI INST OF TECH

Application of tantalum-doped uranium film in black cavity

ActiveCN109036589AImprove coupling efficiencyImprove bindingNuclear energy generationVacuum evaporation coatingStructural reliabilityHigh energy

The invention relates to an application of a tantalum-doped uranium film in a black cavity, belonging to the technical field of laser fusion engineering, and particularly relating to an application ofa tantalum-doped uranium film. The invention aims to solve the problem that in the existing uranium black cavity, the gold lining laser-X-ray conversion efficiency is insufficient, and the physicallyexpected non-lining uranium black cavity is poor in chemical stability, and the structure of the black cavity is not stable. The tantalum-doped uranium film is used as a black cavity lining protective layer or is applied to a black cavity as an energy conversion layer. The tantalum-doped uranium film has the advantages of being good in antioxidant corrosion resistance; as the lining protection layer, having the better interface bonding force and chemical compatibility, and higher energy coupling efficiency while protecting the uranium black cavity energy conversion layer; as the energy conversion layer, having the higher laser-X-ray conversion efficiency compared with Au and lower M-band X-ray yield, and being outstanding in chemical stability and structural reliability.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

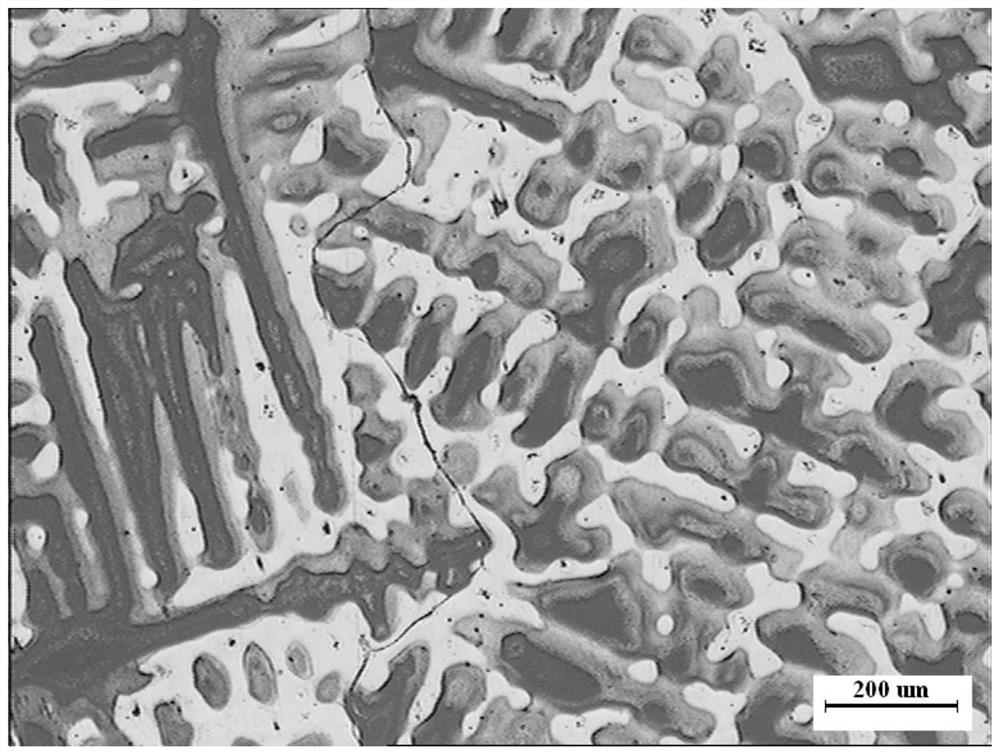

Tantalum-containing cast nickel-based superalloy for 700 DEG C unit and preparation method thereof

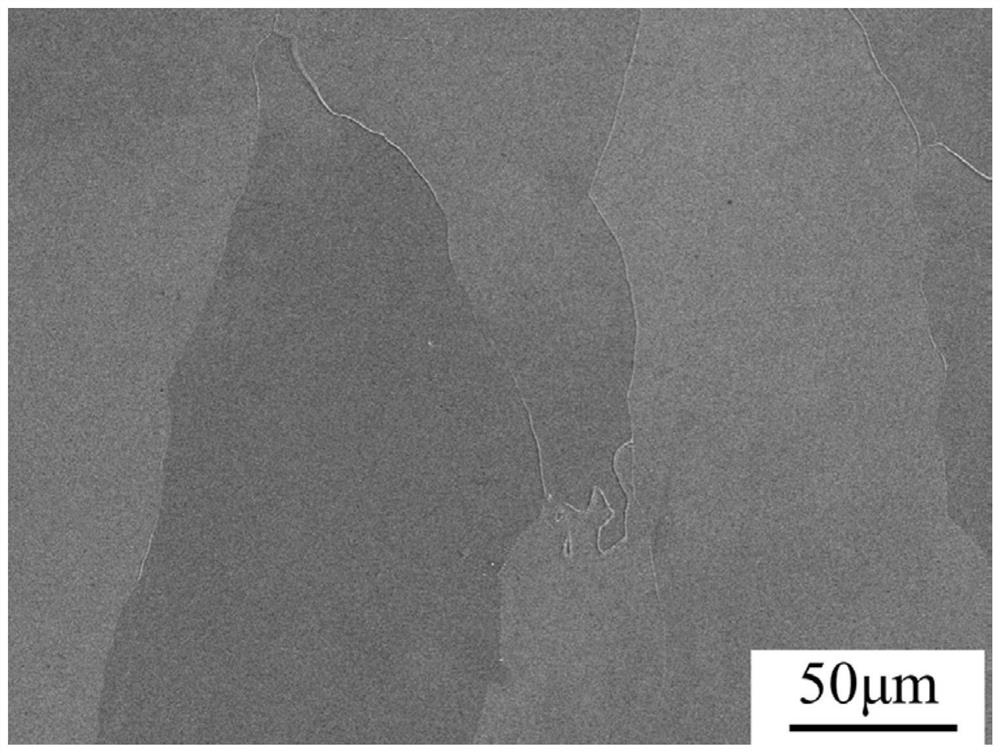

The invention discloses a tantalum-containing cast nickel-based high-temperature alloy for a 700 DEG C unit and a preparation method thereof. The alloy comprises the following components in percentage by mass: 0.2-2.0% of Ta, 20-23% of Cr, 11-13% of Co, 8-9% of Mo, 1.2-2.4% of Al + Ti, less than or equal to 1% of Nb, less than or equal to 0.06% of C, less than or equal to 0.004% of B and the balance of Ni. The method comprises the following steps: (1) preparing raw materials according to set components; (2) smelting under a vacuum condition; (3) refining and removing impurities, and then carrying out vacuum pouring; (4) keeping the vacuum condition until the molten steel forms a film, and discharging to prepare a cast ingot; and (5) preserving heat at 1150-1200 DEG C for 1-2 hours, carrying out solution treatment, and carrying out water cooling. According to the invention, the strength of the solid solution is ensured by utilizing the matching of several elements including the Ta element, meanwhile, a more stable precipitated phase is formed, the coarsening of a grain boundary is inhibited, and meanwhile, the optimal chemical component range, the optimal element adding proportion and the optimal heat treatment process system are determined.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

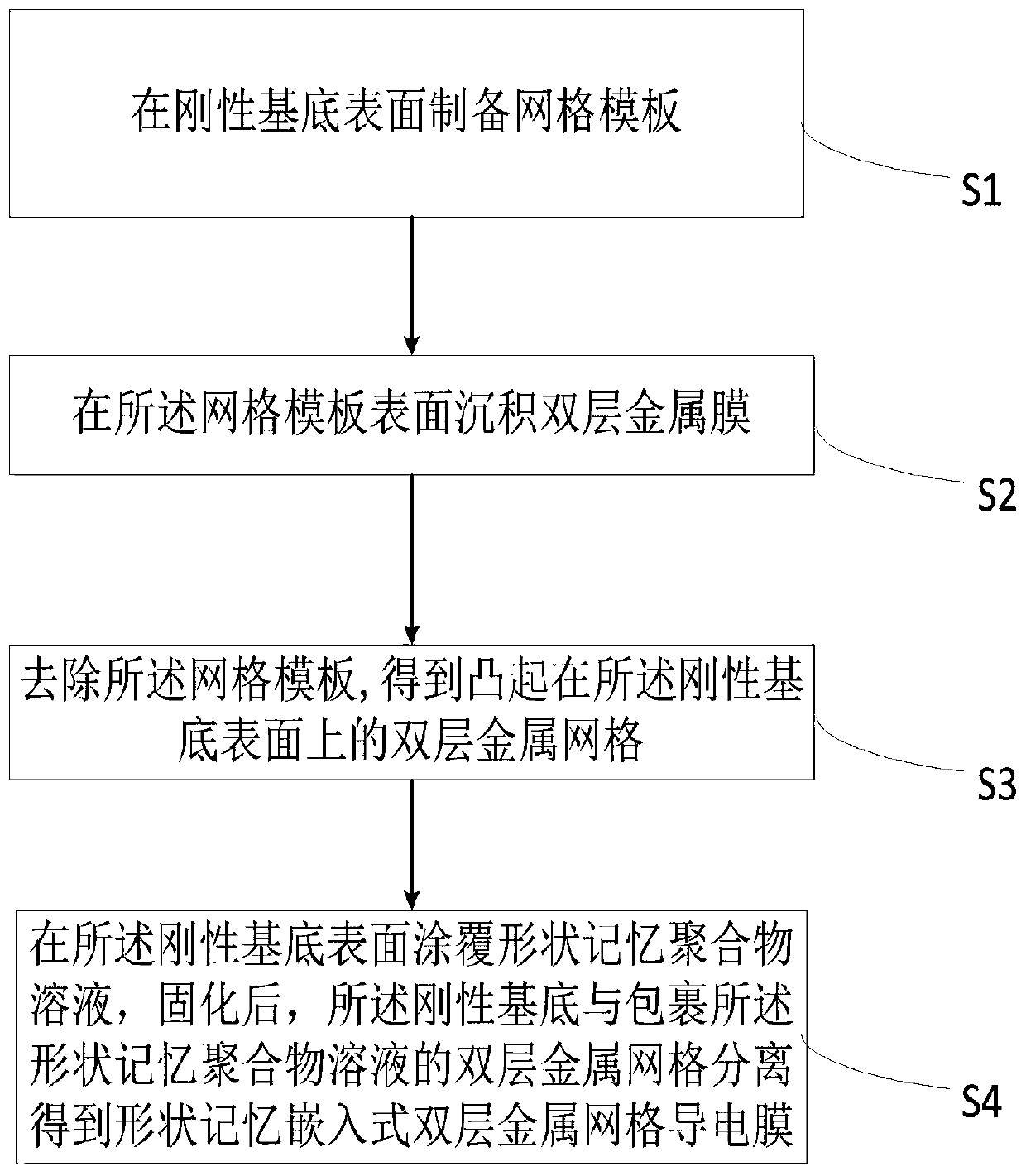

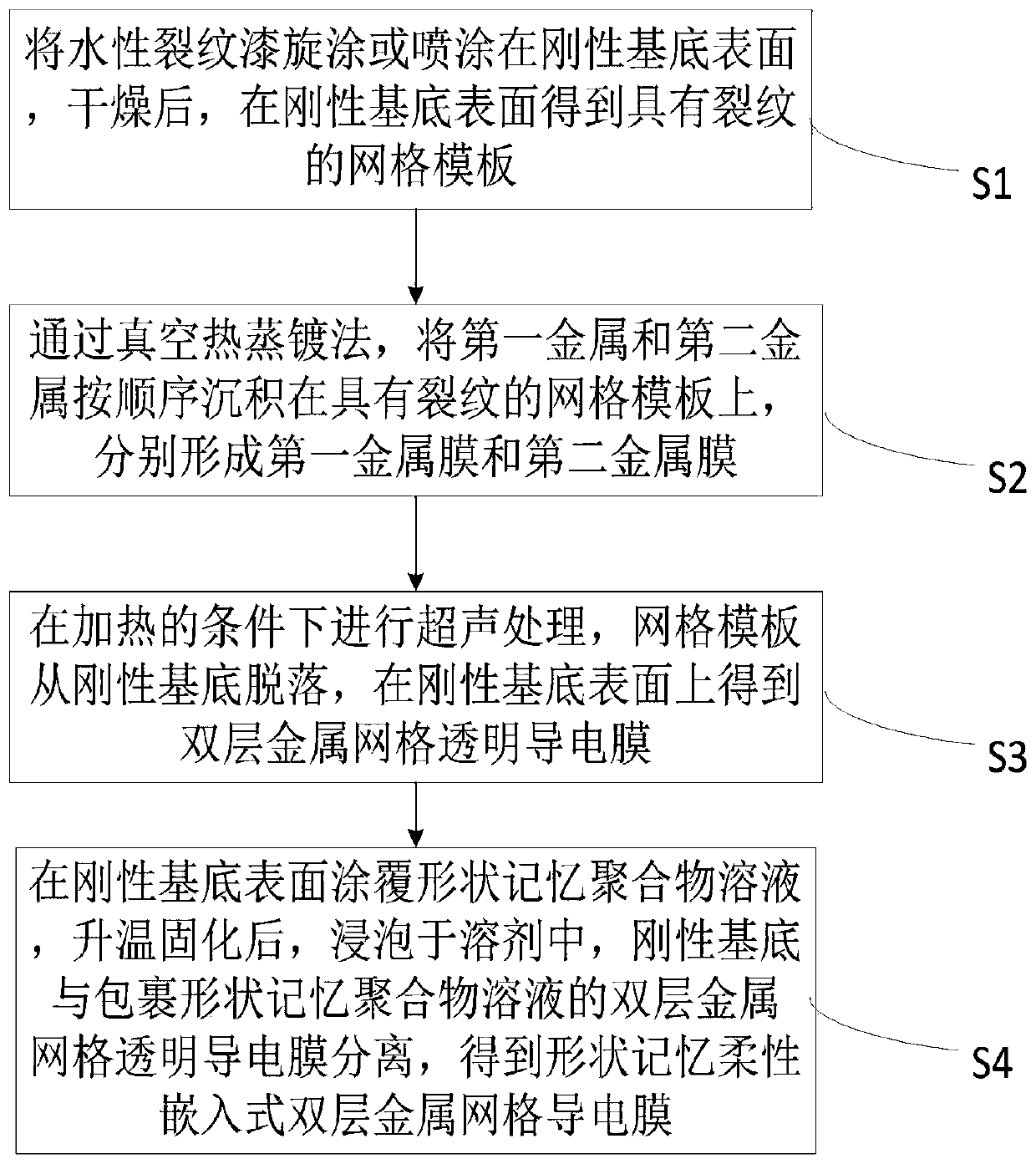

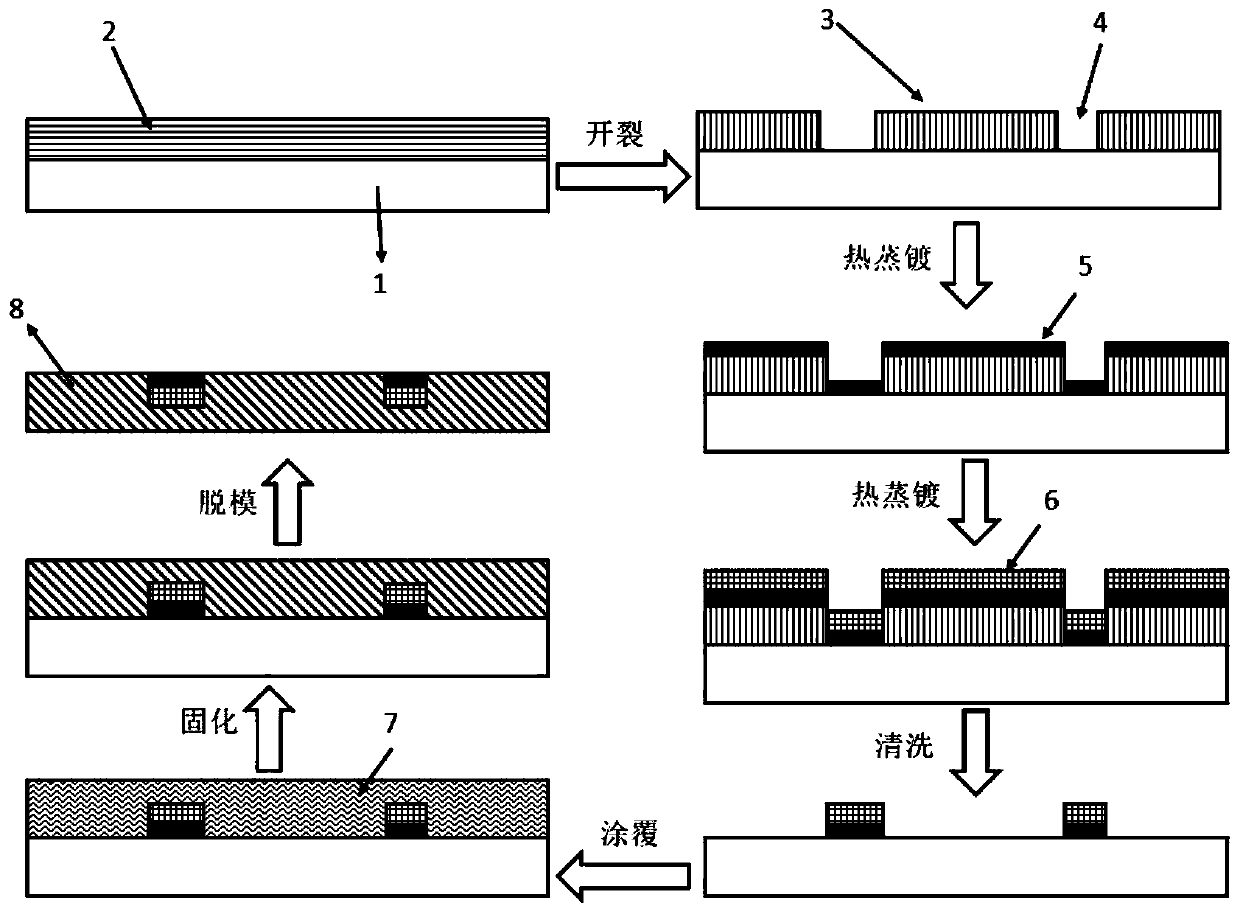

Shape memory embedded double-layer metal grid conducting film and preparation method thereof

InactiveCN110838386AGood scratch resistanceReduce surface roughnessConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersMetal gridElectrically conductive

The invention provides a shape memory embedded double-layer metal grid conducting film and a preparation method thereof, which belong to the technical field of flexible photoelectrons. The preparationmethod for the shape memory embedded double-layer metal grid conducting film comprises the following steps of: preparing a grid template on the surface of a rigid substrate, depositing a double-layermetal film on the surface of the grid template, removing the grid template to obtain a double-layer metal grid protruding on the surface of the rigid substrate, and coating the surface of the rigid substrate with a shape memory polymer, and after curing, separating the rigid substrate from the double-layer metal grid wrapping the shape memory polymer to obtain the shape memory embedded double-layer metal grid conducting film. Compared with the prior art, the shape memory embedded double-layer metal grid conducting film prepared by the invention has good scratch resistance, bending stability,corrosion resistance, oxidation resistance and shape memory performance.

Owner:HARBIN INST OF TECH

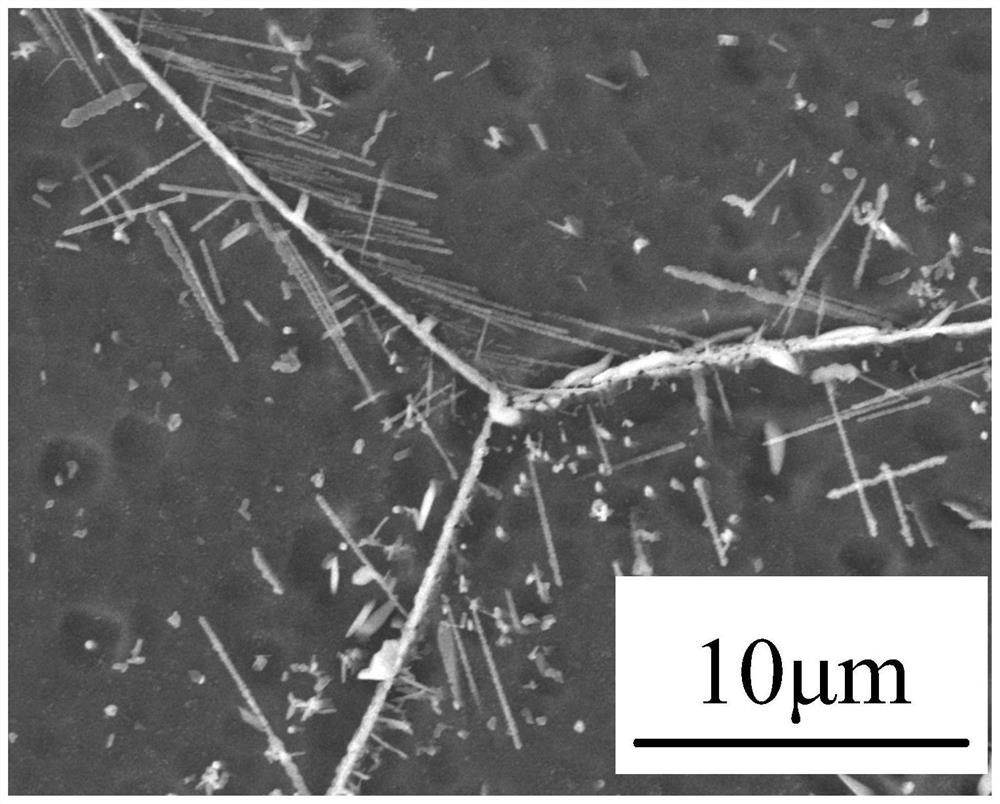

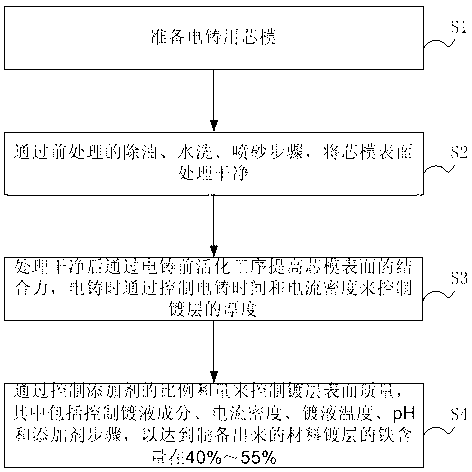

NdFeB (neodymium iron boron) surface modified permanent magnetic material and preparation method thereof

InactiveCN103208342AImprove uniformityGood oxidation and corrosion resistanceMagnetic materialsElectrodesElemental compositionAlloy

The invention discloses an NdFeB (neodymium iron boron) surface modified permanent magnetic material and a preparation method thereof. An intermetallic compound of Re2Fe-14B is used as a matrix for the NdFeB surface modified permanent magnetic material, and a permanent magnetic material of a nickel-iron alloy plating layer is electroplated on the surface. The nickel-iron alloy plating layer is formed by two elements of Ni and Fe, wherein the content of Ni is 45-60 percent, and the content of Fe is 40-55 percent; and the preparation method of the nickel-iron alloy plating layer comprises the following steps that an electroplating method is adopted, a sulfate system is taken as electroplating liquid, the matrix of Re2Fe-14B is taken as a cathode, graphite is taken as an anode, and the nickel-iron alloy plating layer is deposited on the cathode to carry out surface modification. By the adoption of the electroplating process, the obtained product is smooth, has no burrs, and is high in precision, and bright in plate surface, the surface uniformity is within 5 percent, and the production cost is low.

Owner:KUN SHAN POWER STENCIL

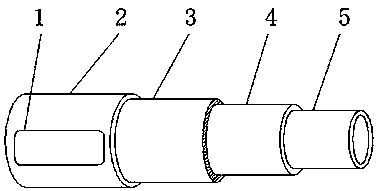

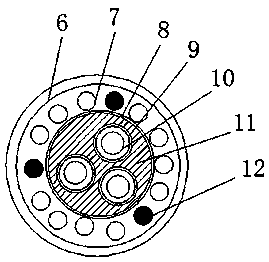

Oxidation-resistant low-temperature-resistant cable

InactiveCN109616250AGood oxidation and corrosion resistanceIncrease elasticityInsulated cablesInsulated conductorsInsulation layerLiquid nitrogen cooling

The invention discloses an oxidation-resistant low-temperature-resistant cable. The oxidation-resistant low-temperature-resistant cable comprises an outer protection sleeve, a heat preservation layer,a liquid nitrogen cooling layer, a protection layer, a high-voltage insulation layer and an insulation protection sleeve; the surface of the outer protection sleeve is provided with a model mark; a braided shielding layer is arranged inside the outer protection sleeve, and the heat preservation layer is arranged inside the braided shielding layer; the liquid nitrogen cooling layer is arranged inside the heat preservation layer; the protection layer is arranged in the liquid nitrogen cooling layer; the high-voltage insulation layer is arranged in the protection layer; the insulation protectionsleeve is arranged inside the high-voltage insulation layer; a filling layer is arranged in the high-voltage insulation layer; power lines are installed inside the insulation protection sleeve; and ground wires are arranged in the protection layer. According to the cable, a low-temperature-resistant anti-oxidation structure is prepared by adopting the outer protection sleeve which is prepared from a low-temperature-resistant silicone rubber material, so that the cable has very high anti-oxidation corrosion resistance, high elasticity and scratch resistance, longer service life and higher economic benefit.

Owner:ZHENJIANG CHANGHE ELECTRIC POWER TECH

Energy-saving and environment-friendly door and window sealing rubber strip and preparation method thereof

The invention discloses an energy-saving and environment-friendly door and window sealing rubber strip and a preparation method thereof and relates to the technical field of energy-saving materials. The sealing rubber strip is prepared from the following raw materials: modified terpene resin, methyl acrylate, powder nitrile butadiene rubber, activated attapulgite clay, composite enhanced fibers, zinc stearate, sodium metasilicate, sodium dodecyl sulfate, diphenyl phosphate, dimethyl sulfoxide, hindered phenol, an anti-radiation agent, a crosslinking agent and a plasticizer. The preparation method of the energy-saving and environment-friendly door and window sealing rubber strip comprises the steps of mixing, extruding the raw materials and the like. The sealing rubber strip disclosed by the invention is simple and convenient to operate and low in production cost, has excellent mechanical strength, fireproof and flame-retarding performance, heat-insulation and sound-blocking performance, and corrosion-resisting and ageing-resisting performance; the sealing rubber strip is widely applied and the utilization performance and the service life are greatly improved.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

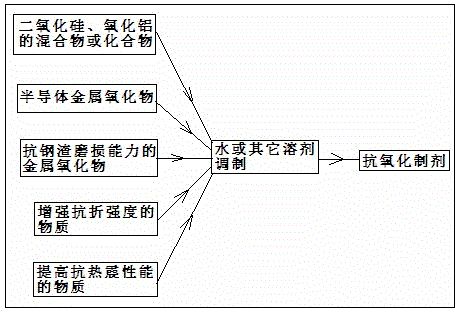

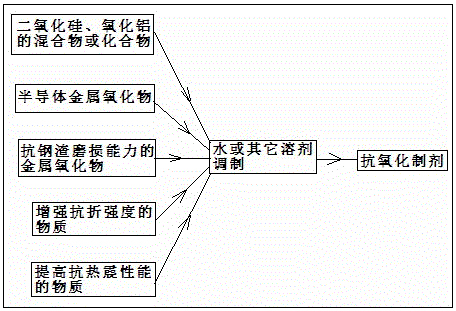

Oxidation-prevention preparation for carbon product

ActiveCN105110816AGood resistance to oxidation and corrosionGood thermal shock resistanceSolventHigh oxygen

The invention provides an oxidation-prevention preparation for a carbon product. With water or other solvents for modulation, the oxidation-prevention preparation can be attached to the outer surface of the carbon product and forms an oxidation-prevention thin layer after being dried or sintered, and the oxidation-prevention preparation contains a mixture or a compound of silicon dioxide and aluminum oxide and additionally contains various components capable of improving the physical property of the oxidation-prevention thin layer. The oxidation-prevention preparation comprises a semiconductor metallic oxide improving electric conductivity and a metal oxide having the capability of resisting slag abrasion and can have a substance improving the thermal shock resistance. The oxidation-prevention preparation has good oxidation corrosion resistance, good slag abrasion resistance, very good thermal shock resistance in high-temperature and high-oxygen environments and long in service life.

Owner:NANTONG YANGZI CARBON

Lead-acid storage battery positive electrode for electric bicycle

ActiveCN102403510AReduce wasteSimple recipeLead-acid accumulator electrodesMechanical engineeringChemistry

The invention discloses a lead-acid storage battery positive electrode for an electric bicycle. The positive electrode consists of the following components in percentage by weight: 1.2 to 1.6 percent of Sn, 0.2 to 0.6 percent of Al, 0.01 to 0.02 percent of Bi, 0.02 to 0.08 percent of Ag, 0.02 to 0.05 percent of In, 0.05 to 0.10 percent of Cu, and the balance of Pb.

Owner:海安华达石油仪器有限公司

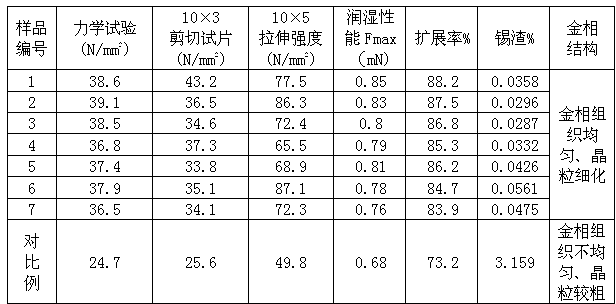

Sn-Cu-Ni-Ce-Cr lead-free solder and preparation method thereof

InactiveCN102990250AGood oxidation and corrosion resistanceImprove high temperature oxidation resistanceWelding/cutting media/materialsSoldering mediaElectronic materialsMechanical property

The invention discloses a Sn-Cu-Ni-Ce-Cr lead-free solder which comprises the following components by weight percent: 0.5-5.0% of Cu, 0.06-1.0% of Cr, 0.01-1.0% of Ce, 0.01-0.15% of Ni and the balance of Sn. Further, the content of the Cr is 0.2-0.7% through optimization. The lead-free solder has the characteristics that the solder splash yield is high relative to a Sn-Cu-Ni-Ce solder, and the solder splash yield is increased by utilizing the properties of the Cr and adjusting the Cr content, so that the lead-free solder with good mechanical properties, good wettability and strong antioxidant ability are obtained, and can be widely applied to the technical field of electronic materials.

Owner:郴州金箭焊料有限公司

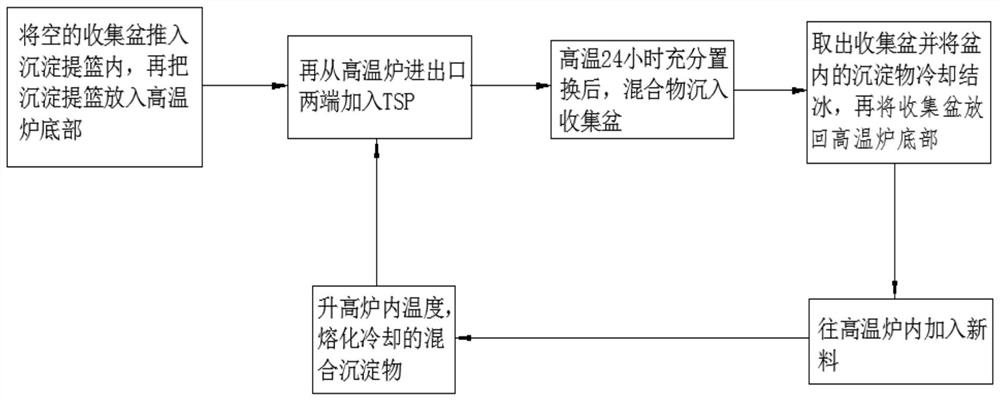

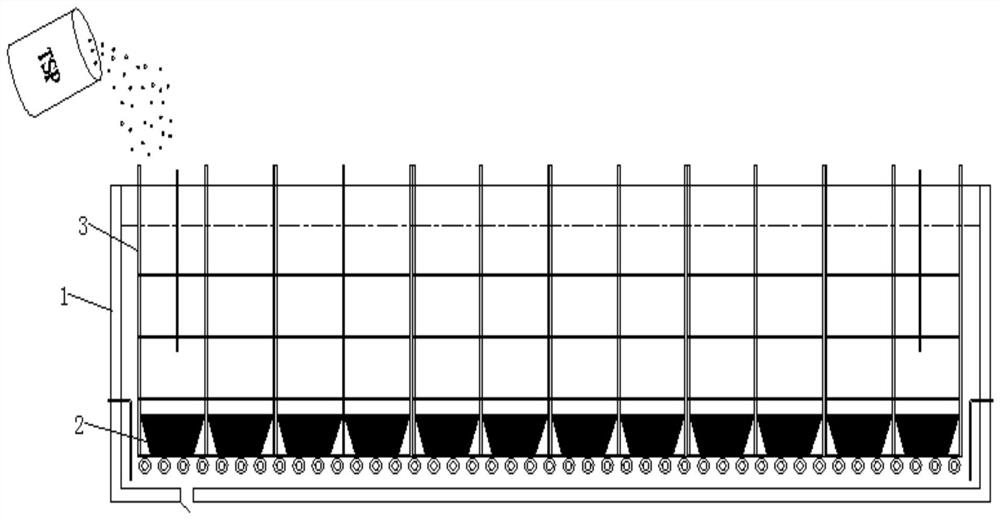

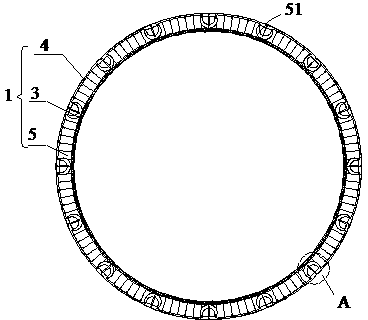

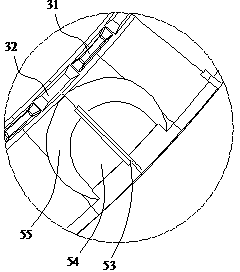

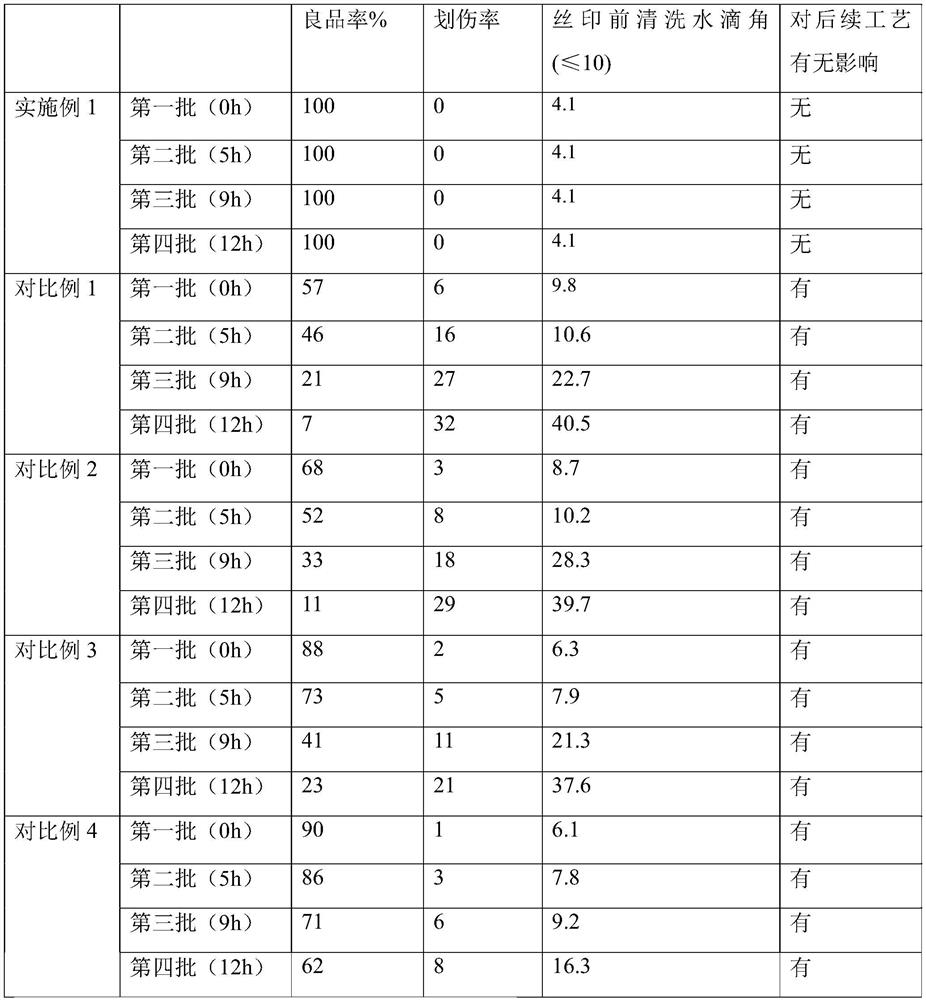

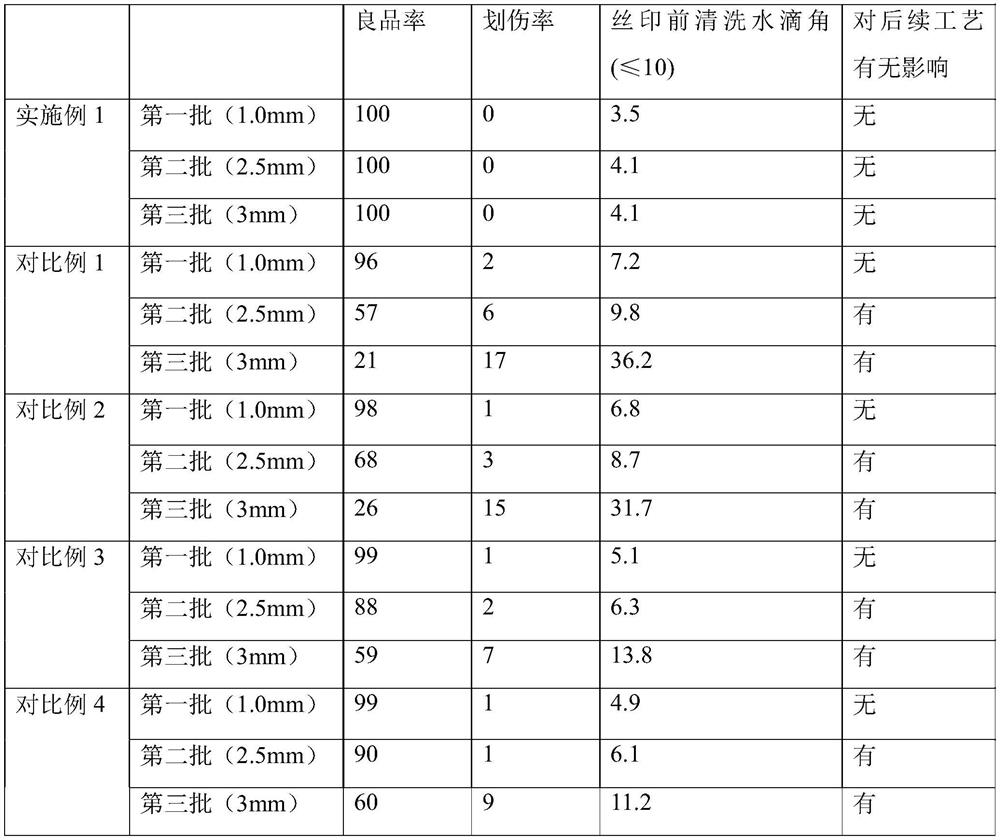

Boiler water high-utilization-rate method

InactiveCN112624629AExtend your lifeEvenly distributedCharge manipulationThermodynamicsPhosphoric acid

The invention relates to a boiler water high-utilization-rate method, which comprises the following steps of: putting a collection basin into the bottom of a high-temperature furnace, adding 3 per thousand to 8 per thousand of anhydrous trisodium phosphate into a high-temperature furnace, heating the high-temperature furnace to 400-500DEG C for processing, taking out the collection basin, cooling and icing collected precipitates, and putting the collection basin back to the bottom of the high-temperature furnace; adding a new material into the high-temperature furnace in proportion, raising the temperature to melt the cooled mixed precipitate, and then reducing the temperature and testing the furnace to produce glass; and raising the temperature in the high-temperature furnace to 450DEG C for processing for 24h. The method further involves a precipitation basket, the collection basin is pushed into the precipitation basket, and then the precipitation basket is placed at the bottom of the high-temperature furnace; the collection basin and the precipitation basket are made of nickel-based alloy; according to the boiler water high-utilization-rate method, a large amount of time and cost are saved, and the production efficiency is remarkably improved.

Owner:伯恩创盛技术研发(惠州)有限公司

Inspection well body components

InactiveCN102767230BImprove support strengthExtended service lifeSewerage structuresStructural engineeringMechanical engineering

The invention discloses a constituent component of an inspection well body, which is formed by integral injection molding and comprises an upper end opening, a lower end opening and a spherical side wall, wherein the spherical side wall is provided with a first reinforcing convex part, a second reinforcing convex part and a reinforcing rib; the upper end opening is provided with a clamping bump and a clamping groove; the first reinforcing convex part is arranged at the inner side of the spherical side wall; the second reinforcing convex part is arranged at the outer side of the spherical side wall and extends from the upper end opening to the middle position of a main body part to form smooth transition; the reinforcing rib is arranged at a concave part of the outer side of the first reinforcing convex part; and the lower end opening is provided with a butt-joint lump and a butt-joint groove. The constituent component of the inspection well body has the following benefits: the height of the inspection well body can be adjusted; the service life of the constituent component of the inspection well body is prolonged; and the universalization is enhanced, the construction is convenient, the airtightness is good, and the oxidation-corrosion resistance is excellent.

Owner:NINGXIA DALIN TECH

A positive electrode of lead-acid storage battery for electric bicycle

ActiveCN102403510BReduce wasteSimple recipeLead-acid accumulator electrodesMetallurgyLead–acid battery

The invention discloses a lead-acid storage battery positive electrode for an electric bicycle. The positive electrode consists of the following components in percentage by weight: 1.2 to 1.6 percent of Sn, 0.2 to 0.6 percent of Al, 0.01 to 0.02 percent of Bi, 0.02 to 0.08 percent of Ag, 0.02 to 0.05 percent of In, 0.05 to 0.10 percent of Cu, and the balance of Pb.

Owner:海安华达石油仪器有限公司

Oxidation-resistant preparations for carbon products

The invention provides an oxidation-prevention preparation for a carbon product. With water or other solvents for modulation, the oxidation-prevention preparation can be attached to the outer surface of the carbon product and forms an oxidation-prevention thin layer after being dried or sintered, and the oxidation-prevention preparation contains a mixture or a compound of silicon dioxide and aluminum oxide and additionally contains various components capable of improving the physical property of the oxidation-prevention thin layer. The oxidation-prevention preparation comprises a semiconductor metallic oxide improving electric conductivity and a metal oxide having the capability of resisting slag abrasion and can have a substance improving the thermal shock resistance. The oxidation-prevention preparation has good oxidation corrosion resistance, good slag abrasion resistance, very good thermal shock resistance in high-temperature and high-oxygen environments and long in service life.

Owner:NANTONG YANGZI CARBON

Method for improving waterproof performance of rattan chair

InactiveCN108748515AGood mechanical propertiesHigh strengthWood treatment detailsCane mechanical workingWater contentCorrosion resistant

The invention discloses a manufacturing method for improving the waterproof performance of a rattan chair. The method comprises the following operation steps that 1, after being washed cleanly, rattanis placed in modified liquid and subjected to soaking treatment for 4-5 hours, and then the rattan is taken out and dried until the water content is 8-12%; and 2, the surface of the rattan obtained after drying treatment is brushed with waterproof paint, then the rattan is placed in an oven, and after the drying treatment, the rattan is woven into the rattan chair. The rattan chair manufactured by the adoption of the method is excellent in various mechanical properties, high in strength, and excellent in corrosion resistant and oxidization resistant performance, and especially has excellent waterproof performance.

Owner:阜南县富昌恒业工艺品有限公司

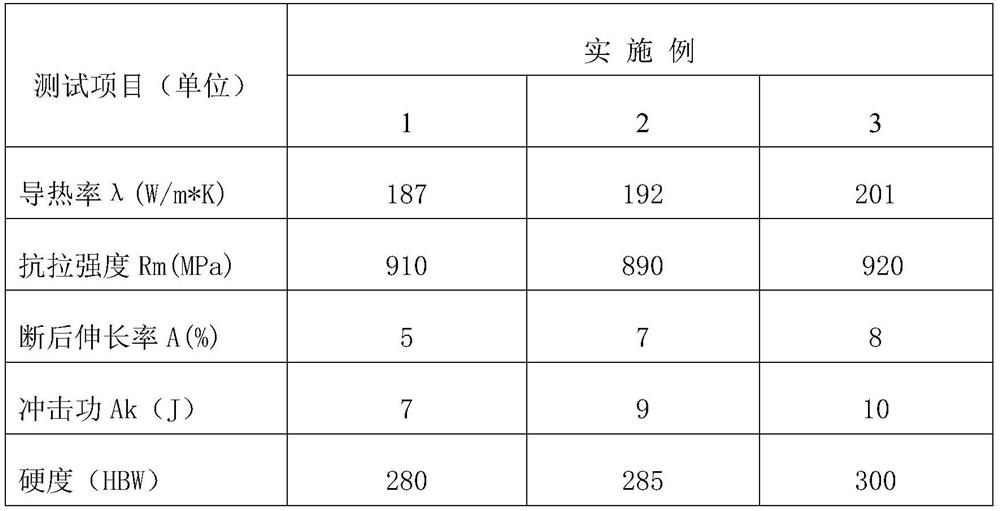

Rare earth copper alloy lightweight glass mold and preparation method thereof

ActiveCN109338155BPurification of ingredientsGood oxidation and corrosion resistanceSolution treatmentSlag

A rare earth-copper alloy lightweight glass mold and a preparation method therefor, relating to the field of glass mold materials. The method comprises: putting weighed nickel, silicon, chromium, 50% of copper, and rare earth into a smelting furnace; after melting, stopping the heating of the furnace and adding the remaining copper; after melting, adding a deslagging agent to cover the melt; performing heating and removing the slags; at the same time, adjusting the melt by means of spectral analysis to contain 4.0-9.5% of nickel, 0.5-3.5% of silicon, 0.5-3.5% of chromium, 0.01-0.5% of rare earth, with the balance being copper; pouring the obtained rare earth-copper alloy lightweight glass mold melt into a molding sand wall in which a cold iron core is provided, and removing the cold iron core after the pouring is completed; introducing the obtained rare earth-copper alloy lightweight glass mold into a solution treatment furnace to perform solution treatment; and then, putting into the furnace to perform aging treatment to obtain a finished product. The mold has high thermal conductivity, high tensile strength, high hardness, excellent oxidation resistance and corrosion resistance.

Owner:CHANGSHU JIANHUA MOLD TECH

A kind of preparation method of wear-resistant and anti-corrosion nickel base alloy wire

Owner:江苏鑫信润科技股份有限公司

A kind of method for preparing anti-oxidation uranium tantalum film on metal uranium surface

ActiveCN108559965BIncreased Atmospheric Storage LifeImprove antioxidant capacityVacuum evaporation coatingSputtering coatingSputteringUranium oxide

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

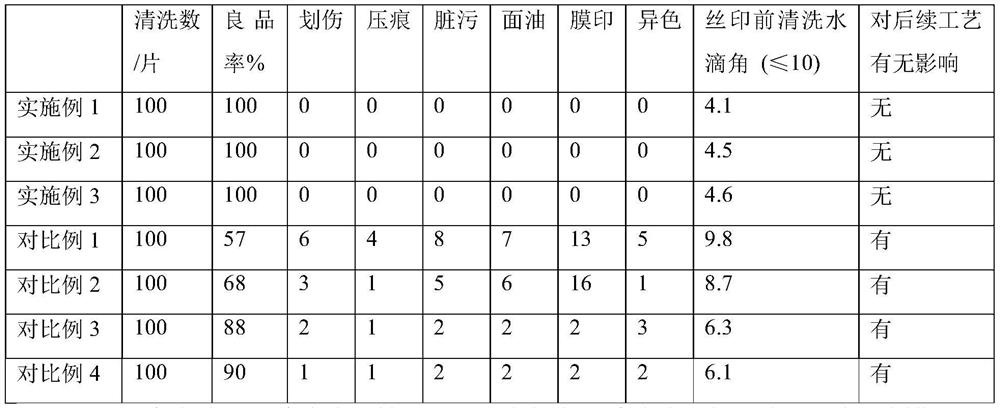

a cleaning powder

ActiveCN110819479BImprove performanceEasy to cleanDetergent mixture composition preparationOrganic non-surface-active detergent compositionsMetallurgyOptical glass

Owner:广州森波化工科技有限公司

Deformation-resistance material fork and manufacturing method thereof

InactiveCN111378889AImprove toughnessHigh temperature resistance and long-lasting strengthComposite material

The invention provides a deformation-resistance material fork and a manufacturing method thereof. By means of the deformation-resistance material fork and the manufacturing method thereof, the deformation resistance of the material fork can be improved, and the service life is prolonged. The deformation-resistance material fork is prepared from, by mass percentage, 0-0.08% of C, 0-1.00% of Si, 0-2.00% of Mn, 0-0.035% of P, 0-0.03% of S, 20% or above of Cr, 12% or above of Ni, 5*C or above of Ti, 0.3-0.60% of Mo, and 0.2-0.4% of Nb.

Owner:TLON TECHN FURNACES WUXI

Oxidation-corrosion-resistant nickel-based alloy

The invention relates to an alloy formula, in particular to an oxidation-corrosion-resistant nickel-based alloy. The nickel-based alloy is characterized by comprising the following components of, by weight, 34-40% of iron, 1.5-2.5% of manganese, 0.02% of aluminum, 0.02% of titanium and the balance nickel. According to the optimal technical scheme, the nickel-based alloy comprises the following components of, by weight, 36% of iron, 2.0% of manganese, 0.02% of aluminum and 0.02% of titanium and the balance nickel. Thus, the oxidation-corrosion-resistant nickel-based alloy has the advantages ofbeing low in cost, good in oxidation corrosion resistant effect and high in corrosion resistance.

Owner:李康宁

A kind of 850 ℃ deformed turbine disk alloy material and preparation process

ActiveCN112226651BGuaranteed ingredientsUniform compositionIncreasing energy efficiencyRare-earth elementMo element

The invention belongs to the field of deformed superalloy materials for aero-engine turbine discs; it relates to a deformed turbine disc alloy material for 850°C and a preparation process; the invention generates carbides in the alloy by adding higher element C, and through control The addition of W and Mo elements avoids the precipitation of TCP phase in the alloy; adding trace rare earth elements to the alloy for composite microalloying, further improving the thermal strength of the alloy, and using pre-melted slag containing rare earth elements for electroslag remelting. The electroslag used for remelting adds trace rare earth elements to ensure the alloy composition; the segregation of the ingot composition is small; the alloy of the present invention uses a small-sized electrode ingot, and at the same time, combined with the triple smelting process, it helps to reduce the alloy composition segregation. The alloy prepared by the invention has the advantages of uniform composition, good high-temperature mechanical properties and the like, and can meet the requirements of high-thrust ratio advanced aero-engines for high-performance deformed alloy turbine disk materials.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

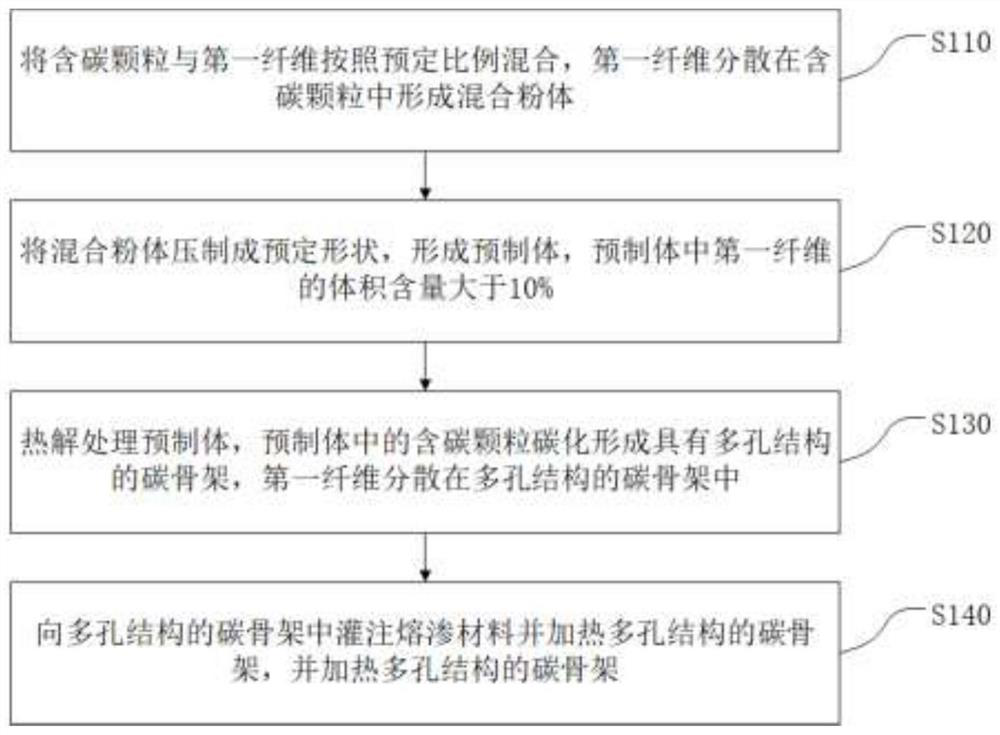

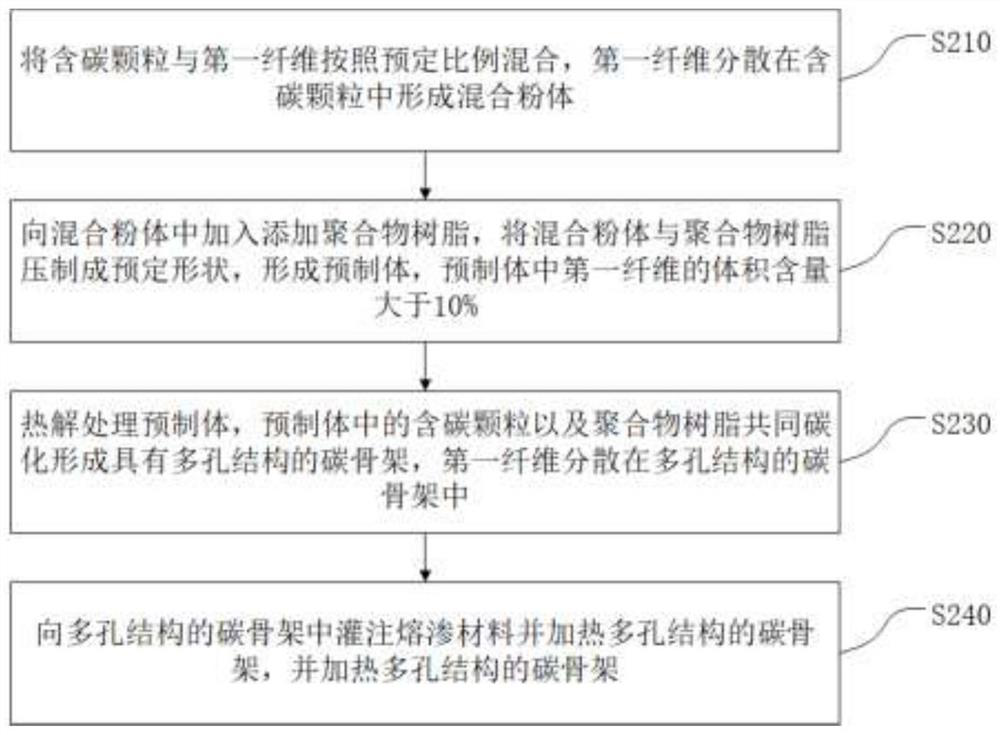

Carbide composite material and production method and product thereof

The invention discloses a carbide composite material and a production method and a product thereof, and the production method comprises the following steps: mixing carbon-containing particles and first fibers according to a preset proportion, and dispersing the first fibers in the carbon-containing particles to form mixed powder; the mixed powder is pressed into a preset shape, a prefabricated body is formed, and the volume content of the first fibers in the prefabricated body is larger than 10%; performing pyrolysis treatment on the preform, carbonizing the carbon-containing particles in the preform to form a carbon skeleton with a porous structure, and dispersing the first fibers in the carbon skeleton with the porous structure; the carbon skeleton of the porous structure is filled with an infiltration material, the carbon skeleton of the porous structure is heated, the infiltration material and carbon in the carbon skeleton of the porous structure are subjected to an infiltration reaction to form a carbide composite material, and the first fibers are dispersed in the carbide composite material to toughen the carbide composite material. The carbide composite material prepared by the production method provided by the invention has good high-temperature oxidation resistance and wear resistance, and has bending strength of 140 MPa or above.

Owner:施远

Anode alloy material of lead-acid battery of electric vehicle

InactiveCN101609892AImprove conductivityReduce passivation effectCell electrodesDistilled waterAlloy

The invention relates to an anode alloy material of lead-acid battery of an electric vehicle. The alloy specifically comprises the following components by weight percent: 0.04-0.12 percent of Ca, 0.45-1.0 percent of Sn, 0.02-0.06 percent of Al, 0.01-0.02 percent of Bi, 0.02-0.08 percent of Ag, 0.005-0.02 percent of Cu and the balance of Pb. The invention has the advantages of simple formulation, little resistance ratio, favorable anti-oxidant and corrosion-resisting performance, higher oxygen evolution potential, favorable self-discharging performance, maintenance-free performance, excellent service circulation ability, more stable electrochemistry performance and little water splitting during charging. By adopting the tubular opening lead-acid battery made from the alloy, distilled water is not needed to be added so as to bring great convenience for users; besides, the production cost and the resource waste are reduced.

Owner:WEIHAI WENLONG BATTERY

Application of a Tantalum-Uranium-Doped Thin Film in Black Cavity

ActiveCN109036589BImprove coupling efficiencyImprove bindingNuclear energy generationVacuum evaporation coatingStructural reliabilityHigh energy

The invention relates to an application of a tantalum-doped uranium film in a black cavity, belonging to the technical field of laser fusion engineering, and particularly relating to an application ofa tantalum-doped uranium film. The invention aims to solve the problem that in the existing uranium black cavity, the gold lining laser-X-ray conversion efficiency is insufficient, and the physicallyexpected non-lining uranium black cavity is poor in chemical stability, and the structure of the black cavity is not stable. The tantalum-doped uranium film is used as a black cavity lining protective layer or is applied to a black cavity as an energy conversion layer. The tantalum-doped uranium film has the advantages of being good in antioxidant corrosion resistance; as the lining protection layer, having the better interface bonding force and chemical compatibility, and higher energy coupling efficiency while protecting the uranium black cavity energy conversion layer; as the energy conversion layer, having the higher laser-X-ray conversion efficiency compared with Au and lower M-band X-ray yield, and being outstanding in chemical stability and structural reliability.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Surface treatment method of magnesium alloy

InactiveCN107287583AImprove the protective effectGood oxidation and corrosion resistanceMetallic material coating processesAlkalinityWeather resistance

The invention provides a surface treatment method of a magnesium alloy. The surface treatment method comprises the step of sequentially carrying out degreasing, surface conditioning, formation and drying on a magnesium alloy substrate, wherein the alkalinity of a degreasing powder solution adopted during the degreasing process is 30 mol / L to 50 mol / L; the acidity of a surface conditioning agent solution adopted during the surface conditioning process is 5 mol / L to 10 mol / L; and the pH value of a formation reagent adopted during the formation process is 1.8 to 2.8. Compared with the prior art, the surface treatment method has the advantages that a protective film is formed on the surface of a magnesium alloy workpiece through reasonable control of the technological parameters during the degreasing, surface conditioning and formation process, the magnesium alloy has good oxidation corrosion resistance and weather resistance, and the surface treatment method is simple in technology, low in cost and easy to popularize and achieve.

Owner:DONGGUAN EONTEC CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com