GO-doped environment-friendly passivator, and preparation method and application thereof

A passivation agent and environmental protection technology, applied in the direction of metal material coating process, etc., can solve the problems of large environmental pollution of passivation agent, low corrosion resistance and oxidation resistance of passive film on stainless steel surface, etc., and achieves simple and convenient versatility, Easy to maintain and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

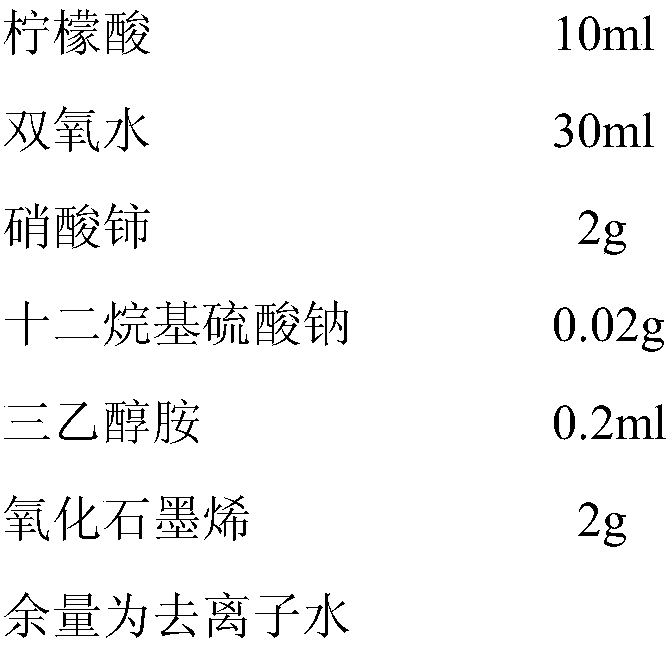

[0036] A new type of environmentally friendly passivator doped with GO, which consists of the following components per liter of passivator:

[0037]

[0038] Weigh or measure sodium lauryl sulfate, citric acid, hydrogen peroxide, cerium nitrate, triethanolamine, and graphene oxide respectively according to the weight ratio and volume ratio, and add them to deionized water to dissolve in order to obtain a new environmentally friendly Deactivator.

Embodiment 2

[0040] The passivating agent that embodiment 1 gained is applied to stainless steel surface and forms passivation film, specifically comprises the steps:

[0041] (1) Stainless steel pretreatment, first clean the stainless steel workpiece with deionized water, then polish and decontaminate it with sandpaper, then ultrasonically clean it in ethanol solution, then clean it in hydrochloric acid solution to remove the surface oxide film, and finally rinse it with deionized water .

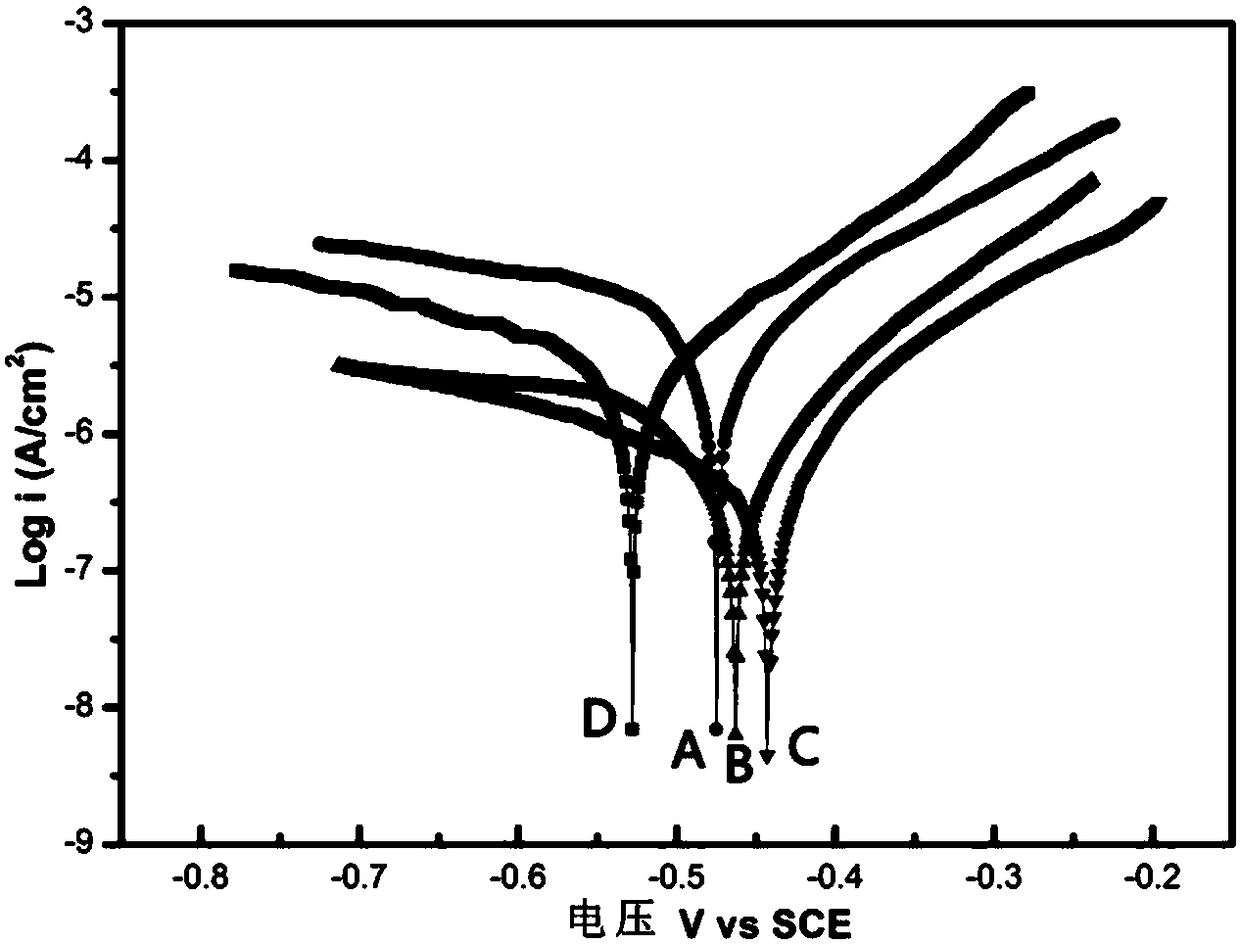

[0042] (2) First heat the prepared passivating agent to 50°C, put the stainless steel workpiece pretreated in step 1 into the passivating agent, passivate for 25 minutes, and dry the sample after completion, that is, form Passivation film sample A that does not contain high-priced chromium, is environmentally friendly, and has excellent corrosion and oxidation resistance. Through the test, the corrosion current density is 1.502×10 –5 cm 2 , the mass gain after oxidation at 170℃ for 10h is 2.94mg / cm ...

Embodiment 3

[0044] A new type of environmentally friendly passivator doped with GO, which consists of the following components per liter of passivator:

[0045]

[0046]

[0047] Weigh or measure sodium lauryl sulfate, citric acid, hydrogen peroxide, cerium nitrate, triethanolamine, and graphene oxide respectively according to the weight ratio and volume ratio, and add them to deionized water to dissolve in order to obtain a new environmentally friendly Deactivator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com