Oxidation-prevention preparation for carbon product

A carbon product, oxidation-resistant technology, applied in the field of surface anti-oxidation treatment reagents, can solve the problem that antioxidant properties cannot be taken into account, and achieve the effects of good oxidation corrosion resistance, workload saving, and good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

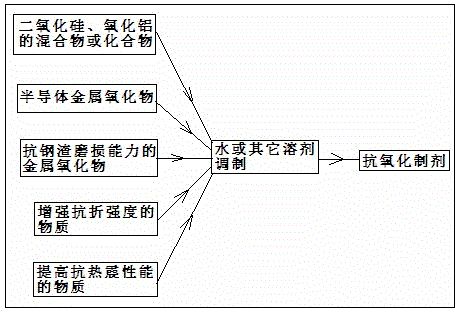

[0024] use as figure 1 The oxidation-resistant preparation of carbon products configured in the process flow shown contains a mixture or compound of silica and alumina, and also contains a variety of ingredients that can improve the physical properties of the anti-oxidation thin layer: semiconducting metals with increased conductivity Oxides, metal oxides with resistance to steel slag wear, substances with improved thermal shock resistance.

[0025] Among them, the semiconductor metal oxide is one or more of Cu2O, NiO, CoO, FeO, and VO2, and the material that improves thermal shock resistance is one or more of MgO, Cr2O3, and graphite powder. The metal oxide is one or more of MgO, Al2O3, SiC, and the refractory fiber material to improve the mechanical properties is C chopped fiber or SiC whisker.

[0026] It is prepared with water or other solvents so that it can adhere to the outer surface of carbon products and form a solid anti-oxidation thin layer after drying or sinterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com