A slurry-type aluminized-silicon protection method for dd6 single crystal superalloy blades

A high-temperature alloy and blade technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of high production cost and limited application scope, and achieve high production efficiency and good oxidation and corrosion resistance. , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

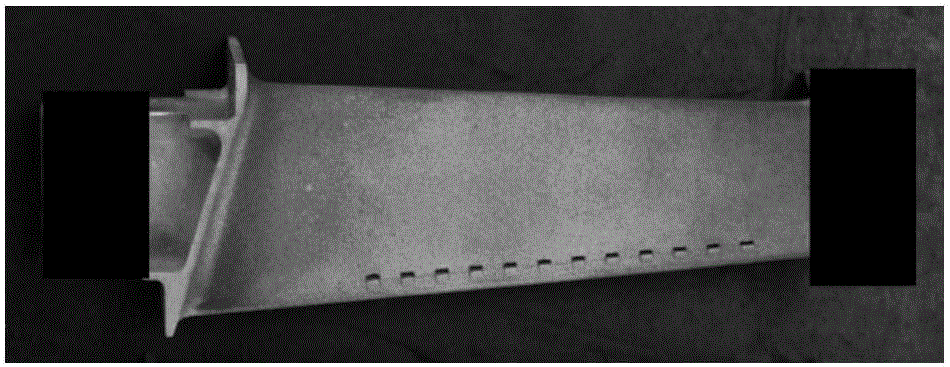

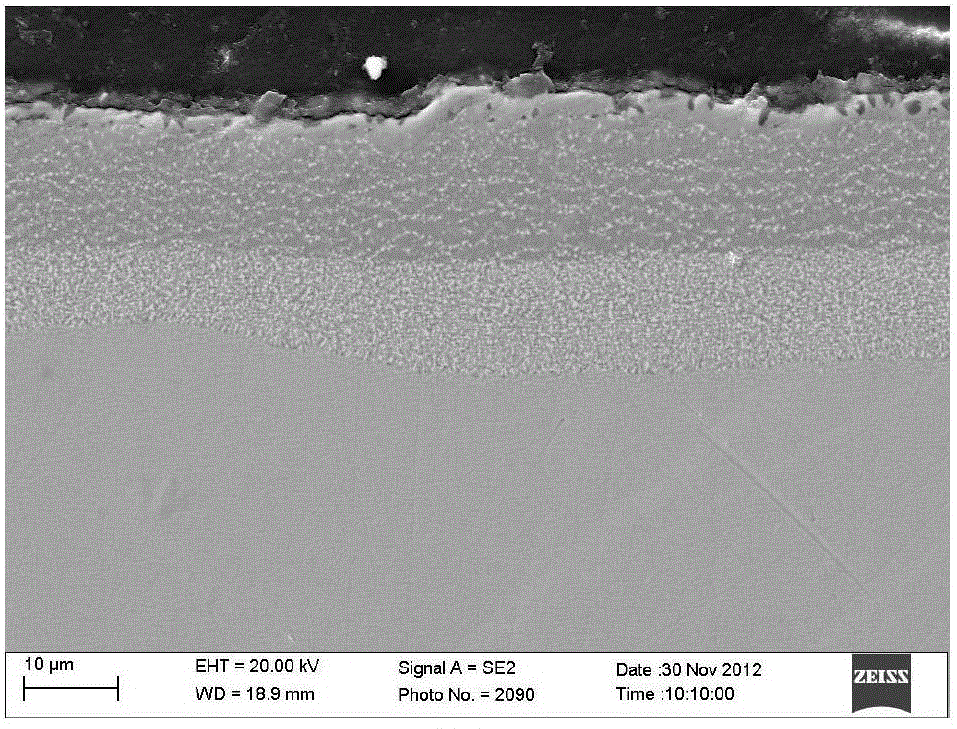

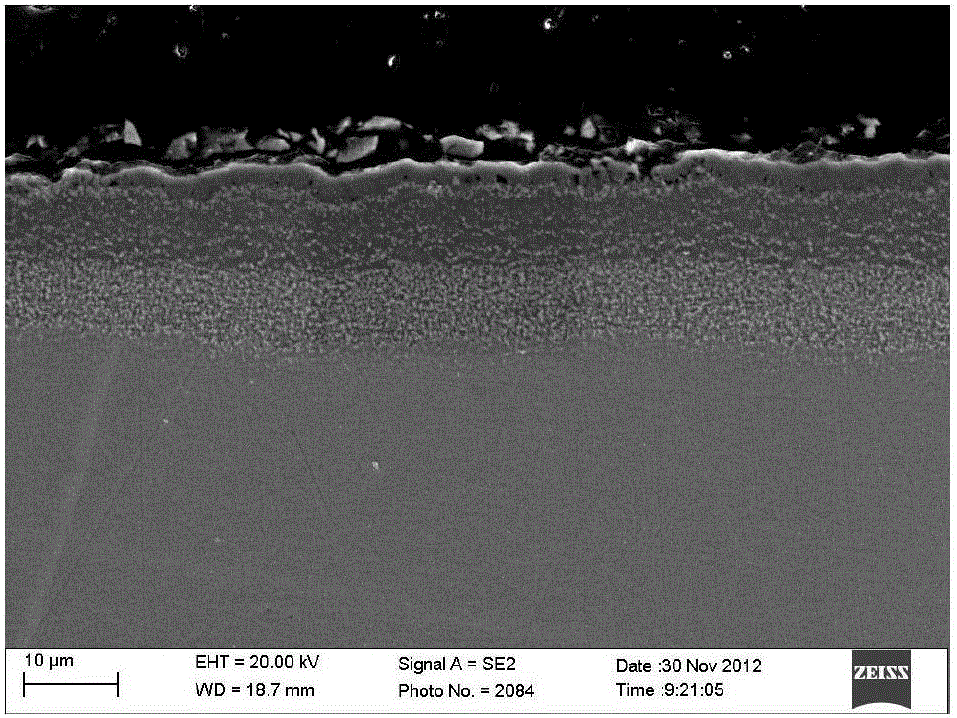

Image

Examples

Embodiment 1

[0027] A slurry-type aluminized silicon protection method for DD6 single crystal superalloy blades is carried out according to the following steps:

[0028] (1) Slurry configuration

[0029] Mix 20% by mass nickel-aluminum alloy powder and 80% silicon powder, then add ammonium chloride with 5% of the total mass of the above two powders, put the above three powders into a ball mill tank for ball milling and roasting to produce penetrating agent;

[0030] Mix polyvinyl alcohol and water at a volume ratio of 2:9, stir evenly and add ethanol solution to dilute to make a binder;

[0031] The volume of added ethanol solution is 1.5 times of the volume of polyvinyl alcohol and aqueous solution;

[0032] Then mix the penetrating agent, binder and ethanol solution to make a slurry; wherein the volume ratio of the quality of the penetrating agent to the binder and the ethanol solution is 100g: 30ml: 100ml;

[0033] (2) Aluminized silicon

[0034] After cleaning and drying the surfac...

Embodiment 2

[0041] A slurry-type aluminized silicon protection method for DD6 single crystal superalloy blades is carried out according to the following steps:

[0042] (1) Slurry configuration

[0043] Mix 20% by mass nickel-aluminum alloy powder and 80% silicon powder, then add ammonium chloride with 5% of the total mass of the above two powders, put the above three powders into a ball mill tank for ball milling and roasting to produce penetrating agent;

[0044] Mix polyvinyl alcohol and water at a volume ratio of 2:9, stir evenly and add ethanol solution to dilute to make a binder;

[0045] The volume of added ethanol solution is 1.5 times of the volume of polyvinyl alcohol and aqueous solution;

[0046] Then mix the penetrating agent, binder and ethanol solution to make a slurry; wherein the volume ratio of the quality of the penetrating agent to the binder and the ethanol solution is 100g: 30ml: 100ml;

[0047] (2) Aluminized silicon

[0048] After cleaning and drying the surface ...

Embodiment 3

[0053] A slurry-type aluminized silicon protection method for DD6 single crystal superalloy blades is carried out according to the following steps:

[0054] (1) Slurry configuration

[0055] Mix 20% by mass nickel-aluminum alloy powder and 80% silicon powder, then add ammonium chloride with 5% of the total mass of the above two powders, put the above three powders into a ball mill tank for ball milling and roasting to produce penetrating agent;

[0056] Mix polyvinyl alcohol and water at a volume ratio of 2:9, stir evenly and add ethanol solution to dilute to make a binder;

[0057] The volume of added ethanol solution is 1.5 times of the volume of polyvinyl alcohol and aqueous solution;

[0058] Then mix the penetrating agent, binder and ethanol solution to make a slurry; wherein the volume ratio of the quality of the penetrating agent to the binder and the ethanol solution is 100g: 30ml: 100ml;

[0059] (2) Aluminized silicon

[0060] After cleaning and drying the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com