Connection structure and preparation method of cermet-based inert anode and guide rod for aluminum electrolysis

A cermet-based, inert anode technology, applied in the field of aluminum electrolysis, can solve the problems of uneven distribution of anode current on the bottom surface of the anode, affecting the stable operation of the electrolytic cell, and consumption of high-quality carbon materials, and achieves excellent resistance to hot corrosive gas corrosion. Antioxidative corrosion, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

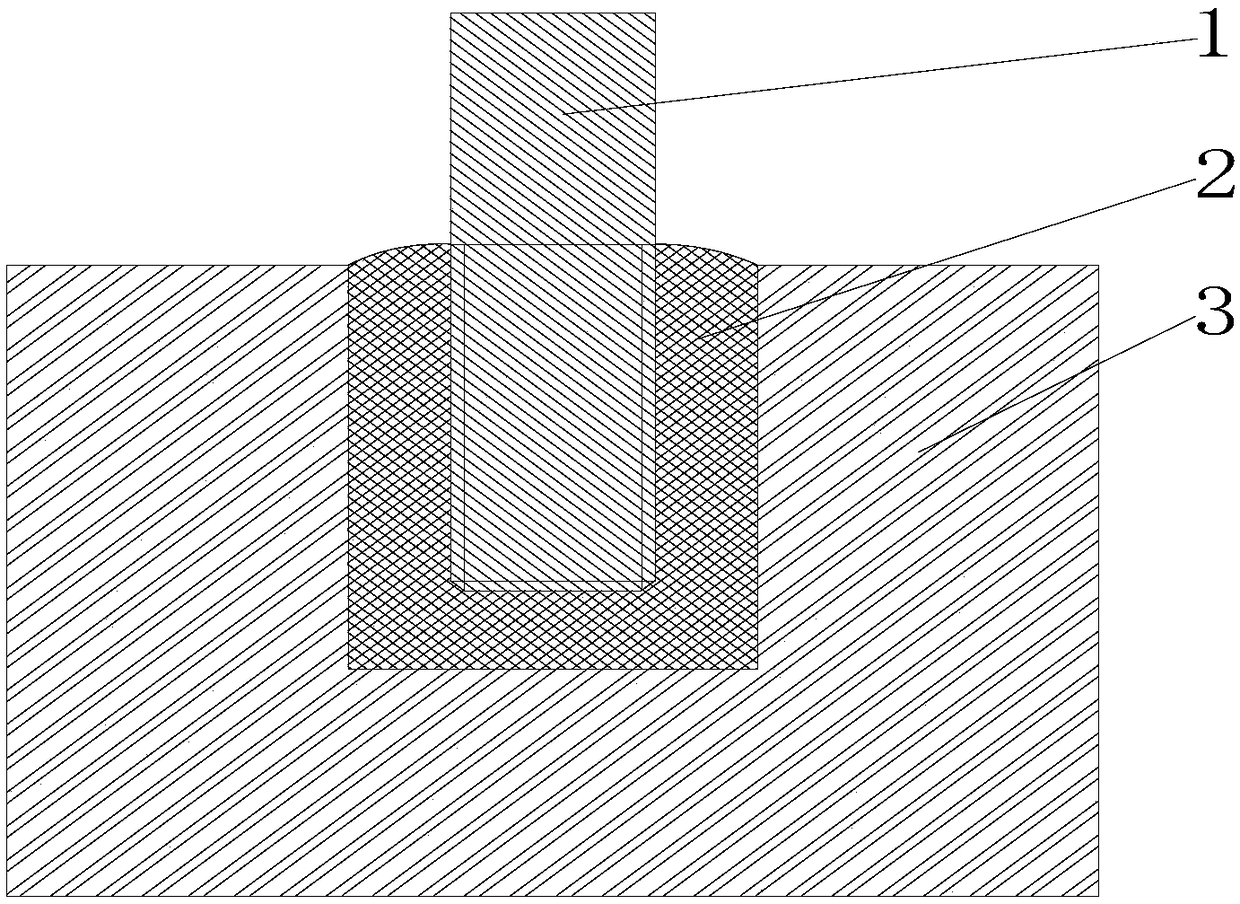

[0036] like figure 1 , depicting a schematic diagram of the joining process of a cylindrical or square cermet-based inert anode to a conductive rod. It mainly includes a metal conductive rod 1, an intermediate alloy ingot 2, and a cylindrical or square cermet-based inert anode 3. The ingredients are

[0037] NiFe 2 o 4 -18NiO-0.5MnO 2 -0.5V 2 o 5 / 17(Cu-20Ni)

[0038] The inert anode, the conductive rod is 310s stainless steel. The implementation process of the connection process is as follows: first drill a cylindrical groove on the upper surface of the cylinder or square cermet-based inert anode, the diameter of the groove is 25mm, and the depth is about 25mm. Metal powder with a composition of 85wt% Cu+15wt% Ni was then pressed into an alloy ingot with a diameter slightly smaller than 25mm. Finally, the alloy ingot is placed into the groove on the upper surface of the inert anode. Put the above-mentioned inert anode and alloy ingot in a high-temperature vacuum fur...

Embodiment 2

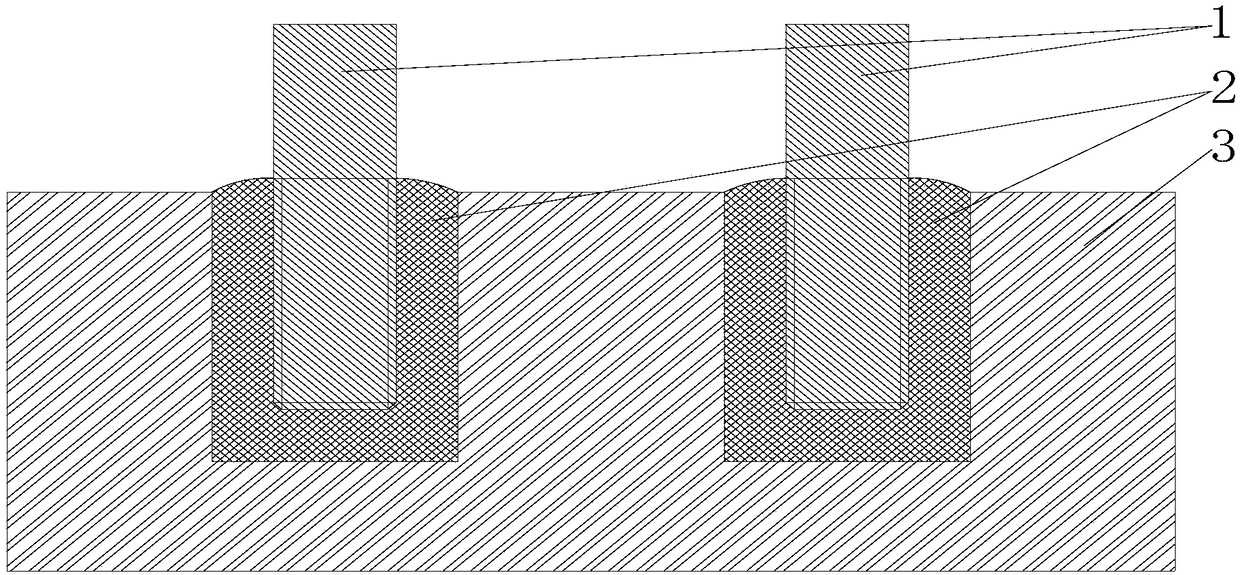

[0040] figure 2 Schematic diagram of the connection process between a large-size strip or rectangular cermet-based inert anode and a conductive rod, mainly including a metal conductive rod 1 , an intermediate alloy ingot 2 , and a cylindrical or square cermet-based inert anode 3 . The composition is NiFe 2 o 4 -18NiO / 17(Cu-20Ni) inert anode, conductive rod is 310s stainless steel. The implementation process of the connection process is as follows: first drill two cylindrical grooves on the upper surface of the cylinder or square cermet-based inert anode, the diameter of the groove is 40mm, and the depth is about 45mm. Then the metal powder with a composition of 80wt% Cu+20wt% Ni was pressed into an alloy ingot with a diameter slightly smaller than 40mm. Finally, the alloy ingot is placed into the groove on the upper surface of the inert anode. Put the above-mentioned inert anode and alloy ingot in a high-temperature vacuum furnace, close the furnace body and evacuate the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com