Ceramic coating ozone generating tube and preparation method thereof

An ozone generating tube and ceramic coating technology, applied in ozone preparation, ceramics, coating and other directions, can solve the problems of low dielectric strength, difficult process realization, environmental pollution, etc., and achieve good oxidation resistance and corrosion resistance, and the preparation conditions are not harsh. , Guarantee the effect of technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

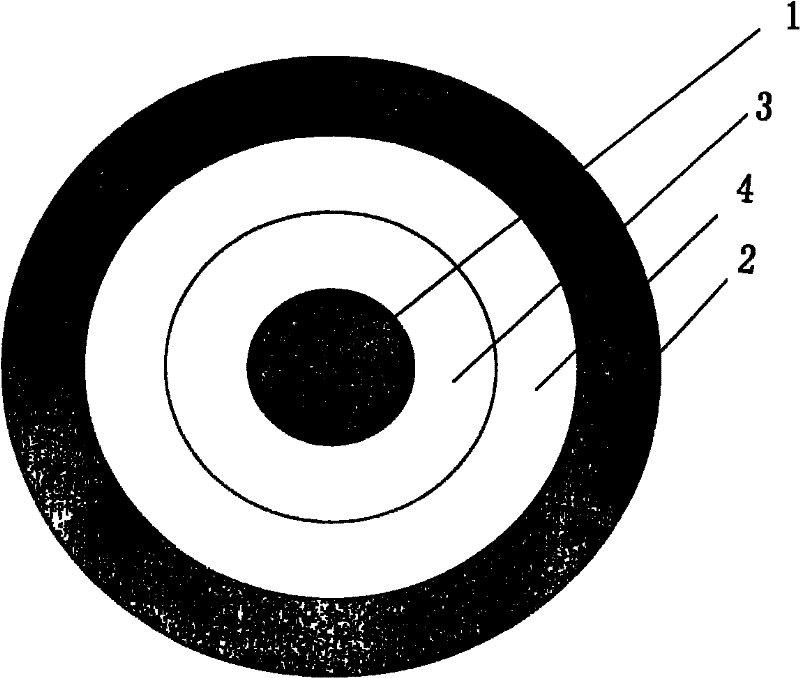

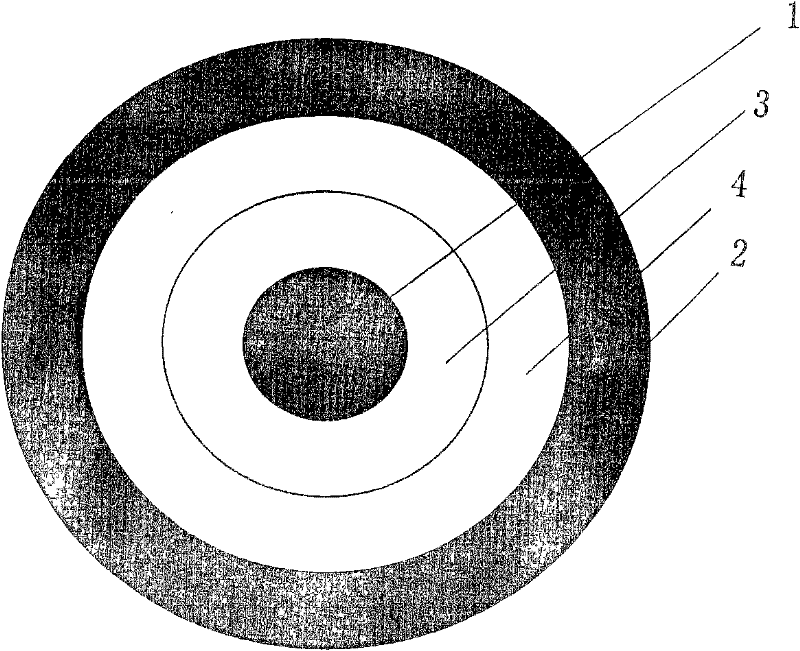

[0027] Please refer to the accompanying drawings, an embodiment structure of the ceramic coating ozone generating tube of the hospital is given, including an internal electrode 1, an external electrode 2, a dielectric layer 3 combined with the outer surface of the internal electrode 1 and being formed between the dielectric layer 3 and the outer surface. The discharge gap 4 between the electrodes 2, wherein the dielectric layer 3 is a ceramic dielectric insulating layer, the specific steps of the preparation method are as follows:

[0028] A) cleaning, putting the internal electrode 1 into an ultrasonic cleaning machine for cleaning, so that the outer surface of the internal electrode 1 forms a clean surface, and the cleaned internal electrode 1 is obtained;

[0029] B) Surface pretreatment, using a sandblasting device to spray 20# white corundum sand on the outer surface of the inner electrode 1, that is, the outer circular surface, so that the outer surface of the inner elect...

Embodiment 2

[0034] Change the current of the plasma spraying equipment in step C) to 430A, the flow rate of argon gas to 150L / min, the flow rate of hydrogen gas to 28L / min, the powder feeding rate to 50g / min, the distance between the nozzle and the workpiece Change it to 20cm, and the ceramic dielectric insulating coating in step D) i.e. Al 2 o 3 The thickness of the dielectric layer 3 is changed to 0.4mm, Al 2 o 3 The compressive strength of the coating is tested to be 10.5-11KV / mm. All the other are the same as the description to embodiment 1.

Embodiment 3

[0036] Only change the spraying material in step C) to use mass percentage content instead, that is, the Y with a purity of > 98% 2 o 3 , the current of the plasma spraying machine is changed to 400A, the flow rate of argon gas is changed to 110L / min, the flow rate of hydrogen gas is changed to 18L / min, the amount of powder feeding is changed to 20g / min, the distance between the nozzle and the workpiece is changed to 10cm, and the In the step D), the ceramic dielectric insulating coating is Y 2 o 3 The thickness of the dielectric layer 3 is changed to 0.3mm, Y 2 o 3 The compressive strength of the coating is tested to be 19.5-19.9KV / mm. All the other are the same as the description to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com