Oxidation-resistant low-temperature-resistant cable

A technology of low temperature resistance and oxidation resistance, used in insulated cables, cables, circuits, etc., can solve the problems of low temperature resistance, low oxidation resistance and anti-corrosion, and achieve the effects of light weight, long service life and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

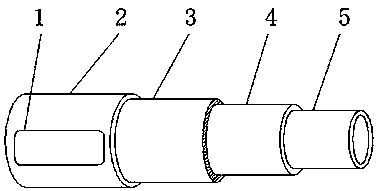

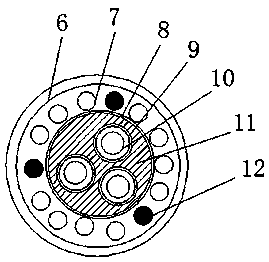

[0015] refer to Figure 1-2 , an anti-oxidation and low-temperature resistant cable, comprising an outer protective sheath 2, an insulating layer 4, a liquid nitrogen cooling layer 5, a protective layer 6, a high-voltage insulating layer 8 and an insulating protective sheath 9, the surface of the outer protective sheath 2 is provided with a model mark 1, A braided shielding layer 3 is installed inside the outer protective cover 2, and an insulation layer 4 is installed inside the braided shielding layer 3, a liquid nitrogen cooling layer 5 is installed inside the insulation layer 4, and a protective layer 6 is installed inside the liquid nitrogen cooling layer 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com