Aqueous acrylic resin, and preparation method and application thereof

A technology of water-based acrylic acid and methacrylic acid, which is applied in the chemical field, can solve the problems of high production cost of polyurethane, environmental pollution, and harmfulness of solvent-based resins to the human body, and achieve cost saving, excellent physical and chemical properties, and improved moldability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

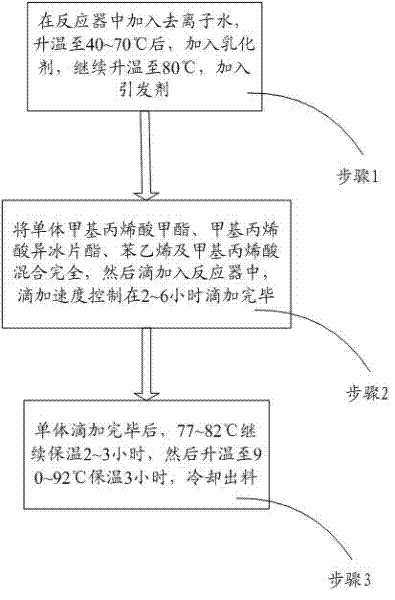

[0053] The preparation method of said water-based acrylic resin is also provided in the present invention, such as figure 1 shown, including the following steps:

[0054] Step 1: Add deionized water into the reactor, heat up to 40~70°C, add emulsifier, continue to heat up to 80°C, add initiator;

[0055] Step 2: Mix the monomers methyl methacrylate, isobornyl methacrylate, styrene and methacrylic acid completely, then drop them into the reactor, and the dropping rate is controlled within 2 to 6 hours to complete the dropping;

[0056] Step 3: After the addition of the monomer is completed, keep the temperature at 77~82°C for 2~3 hours, then raise the temperature to 90~92°C for 3 hours, and then cool and discharge.

[0057] Wherein, in the step 1, the amount of deionized water added is twice the weight of the water-based acrylic resin.

[0058] The polymerization implementation method of the above formula is to use high-efficiency emulsifier EF-810 with traditional sodium dodec...

Embodiment 1

[0062] Described waterborne acrylic resin, according to weight percentage, is made up of following components:

[0063] Methyl methacrylate 50%

[0064] Styrene 20%

[0065] Isobornyl Methacrylate 23%

[0066] Methacrylic acid 4.5%

[0067] Sodium Lauryl Sulfate 1%;

[0068] EF-810 0.5%

[0069] Potassium persulfate 1%.

[0070] The preparation method of described waterborne acrylic resin is as follows:

[0071] Step 1: Add deionized water into the reactor (the amount of deionized water added is twice the weight of the water-based acrylic resin), heat up to 40°C, add an emulsifier, continue to heat up to 80°C, and add an initiator;

[0072] Step 2: Mix the monomers methyl methacrylate, isobornyl methacrylate, styrene and methacrylic acid completely, then drop them into the reactor, and the dropping rate is controlled within 3 hours to complete the dropping;

[0073] Step 3: After the addition of the monomer is completed, keep the temperature at 77°C for 2 hours, then ra...

Embodiment 2

[0082] Described waterborne acrylic resin, according to weight percentage, is made up of following components:

[0083] Methyl methacrylate 54%

[0084] Styrene 18%

[0085] Isobornyl Methacrylate 20%

[0086] Methacrylic acid 5.5%

[0087] Sodium Lauryl Sulfate 1%;

[0088] EF-810 0.5%

[0089] Potassium persulfate 1%.

[0090] The preparation method of described waterborne acrylic resin is as follows:

[0091] Step 1: Add deionized water into the reactor (the amount of deionized water added is twice the weight of the water-based acrylic resin), heat up to 55°C, add an emulsifier, continue to heat up to 80°C, and add an initiator;

[0092] Step 2: Mix the monomers methyl methacrylate, isobornyl methacrylate, styrene and methacrylic acid completely, then drop them into the reactor, and the dropping rate is controlled within 4 hours to complete the dropping;

[0093] Step 3: After the addition of the monomer is completed, keep the temperature at 82°C for 3 hours, then ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com