Adhesive composition, adhesive sheet, and back grinding method for semiconductor wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

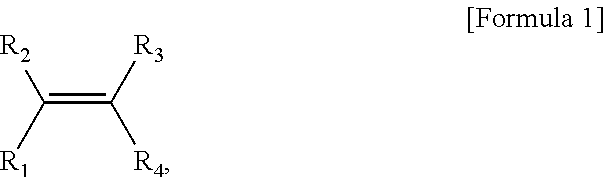

Method used

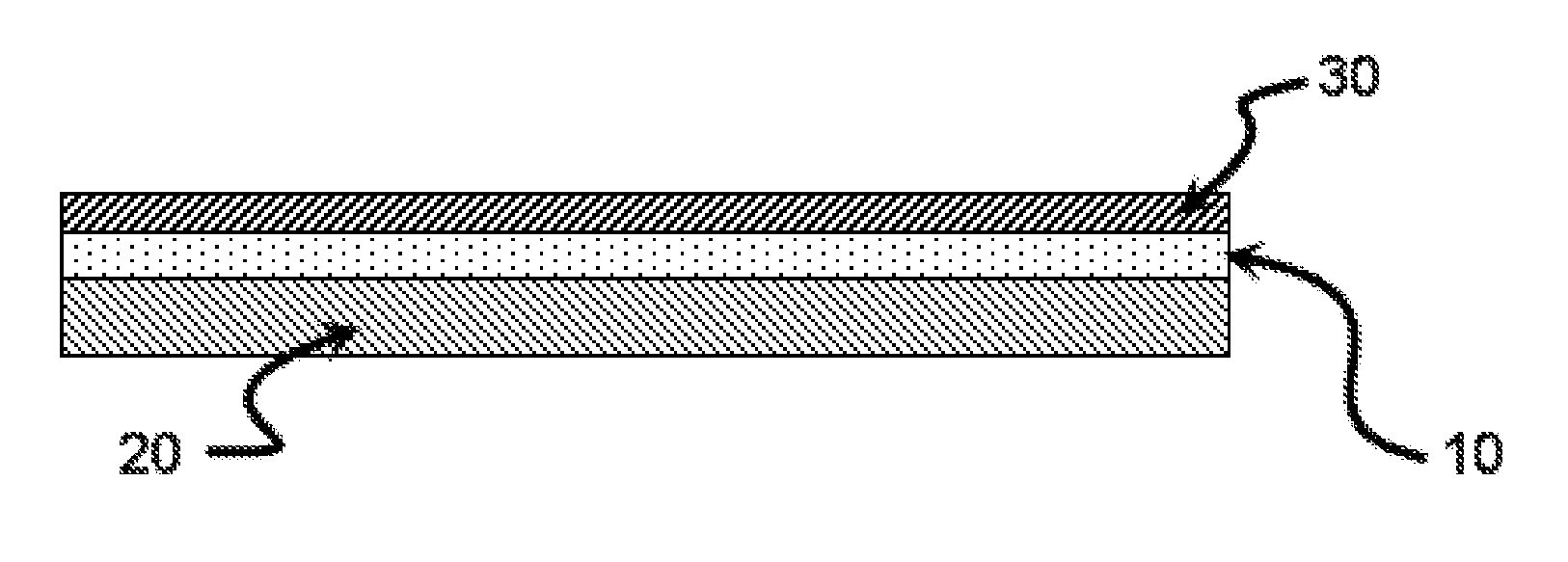

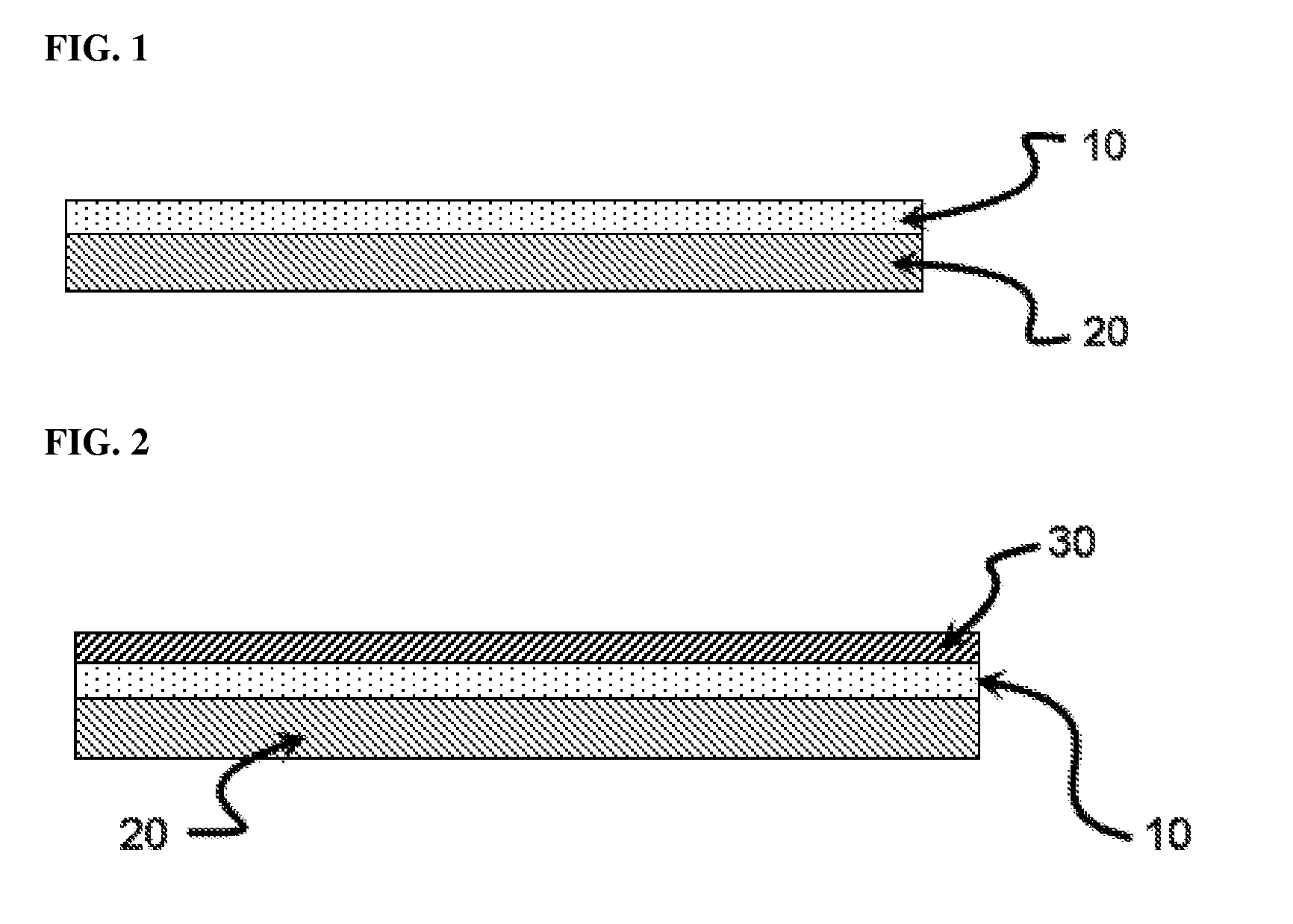

Image

Examples

example 1

[0061]A monomer mixture (100 parts by weight) comprising isobonyl acrylate, methyl acrylate, ethyl acrylate, n-butyl acrylate and 2-hydroxyethyl acrylate was prepared such that 5 parts by weight of isobonyl acrylate (IBOA) were contained in the mixture, and the glass transition temperature of the polymer prepared from the mixture was −25° C. Then, the monomer mixture was polymerized to prepare an acrylic pressure-sensitive adhesive polymer having a solid content of 45 weight %. Next, an isocyanate cross-linking agent was added to the prepared pressure-sensitive adhesive polymer in an amount of 2 parts by weight, relative to 100 parts by weight of the pressure-sensitive adhesive polymer. The resultant was applied to an ethylene-acetic acid vinyl copolymer film having a thickness of 80 μm, and then dried, thus preparing a pressure-sensitive adhesive layer (thickness: 20 μm). The prepared pressure-sensitive adhesive sheet was aged for 2 hours at 50° C., and then subjected to tests to b...

example 2

[0062]Except for the fact that a monomer mixture (100 parts by weight) comprising isobonyl acrylate, methyl acrylate, ethyl acrylate, n-butyl acrylate and 2-hydroxyethyl acrylate was used such that 10 parts by weight of isobonyl acrylate (IBOA) were contained therein and the glass transition temperature of the polymer prepared from the mixture was −9° C., the pressure-sensitive adhesive sheet was prepared in the same manner as Example 1.

example 3

[0063]Except for the fact that a monomer mixture (100 parts by weight) comprising isobonyl acrylate, methyl acrylate, ethyl acrylate, n-butyl acrylate and 2-hydroxyethyl acrylate was used such that 20 parts by weight of isobonyl acrylate (IBOA) were contained therein and the glass transition temperature of the polymer prepared from the mixture was −1° C., the pressure-sensitive adhesive sheet was prepared in the same manner as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com