Polyester modified fluoro acrylic resin, and preparation method and coating thereof

A technology for modification of fluoroacrylic resin and polyester, which is applied in the field of polyester modified fluoroacrylic resin and its preparation for coatings for helicopter skin materials, and can solve the problem that the comprehensive performance of the resin is difficult to meet the design requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of polyester precursors. Put 235 grams of neopentyl glycol, 74 grams of trimethylolpropane, 163 grams of phthalic anhydride, 183 grams of isophthalic acid, 33 grams of toluene, 1.5 grams of dibutyltin oxide, and 3.5 grams of anti-168 into the In the four-neck flask of the device, nitrogen gas was passed, the temperature was raised, and when the material was basically dissolved, stirring was started. Continue to raise the temperature and reflux for dehydration. Before the dehydration reaches 90% of the theoretical value [theoretical water amount is 66 grams], control the temperature at the top of the water separator to not exceed 100°C, and control the reaction temperature of the flask at 160-180°C; when the dehydration amount reaches the theoretical value When the amount of water is 90%, the temperature in the flask gradually increases, but does not exceed 210°C. When the dehydration amount is close to the theoretical value, take the material to measure the...

Embodiment 2

[0039] Varnish preparation. Prepare the coating with the polyester modified fluoroacrylic resin synthesized above, and the basic formula is as follows: polyester modified fluoroacrylic resin, 50 parts by weight; titanium dioxide, 27 parts; dispersant, 2 parts; leveling agent, 1 part; Anti-UV Absorber, 2 parts; Xylene, 10 parts; Isophorone, 5 parts; Propylene Glycol Methyl Ether Acetate, 3 parts. The curing agent adopts DESMODUR N-3390 HDI trimer curing agent. The ratio of white paint and curing agent is 100:25. The thickness of the coating is about 25 μm.

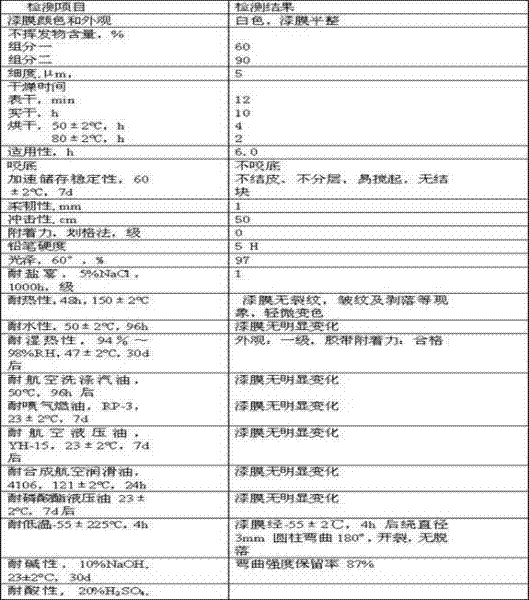

[0040] The prepared paint was tested on the skin material for helicopters, and the measured properties were as follows:

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com