Optical adhesive and preparation method thereof

A technology of optical glue and isocyanate, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of touch screen product quality decline, short service life of optical glue, yellowing, etc., to achieve yellowing and aging The speed drops, the anti-yellowing performance is excellent, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

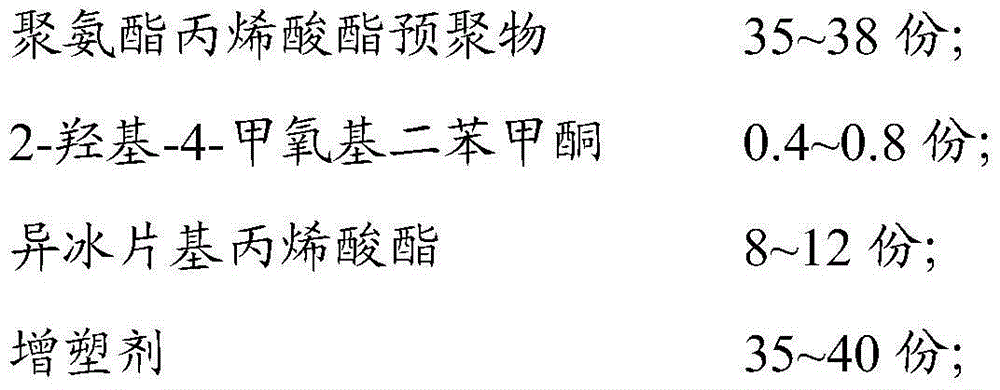

[0027] An optical glue, comprising:

[0028]

[0029] Prepared as follows:

[0030] (1) Preparation of polyurethane acrylate prepolymer

[0031] Add in the flask: heat 129g (0.0645mol) polytetrahydrofuran diol (molecular weight 2000, PTMGE-2000, BASF), 108g (0.036mol) polycaprolactone diol (molecular weight 3000, Daicel, Japan) to 115°C , vacuum dehydration for 2 hours, adopt the Karl Fischer method to measure the moisture content to be below 0.05%, add 0.095g (0.00015mol) dibutyltin dilaurate as catalyst, heat up to 100°C, add dropwise 42.5g (0.17mol) 2 , 2-diphenylmethane diisocyanate, stirred and reacted for 5 hours, then added 12.6g (0.15mol) methacrylate, 0.35g (0.000554mol) dibutyltin dilaurate, 0.16g (0.0007mol) 2-hydroxy- 4-methoxybenzophenone, reacted at 85°C for 7 hours, after the reaction was completed, the isocyanate was measured by infrared spectroscopy at 2270cm -1 The stretching vibration front at the position drops to the same, that is, the isocyanate gro...

Embodiment 2

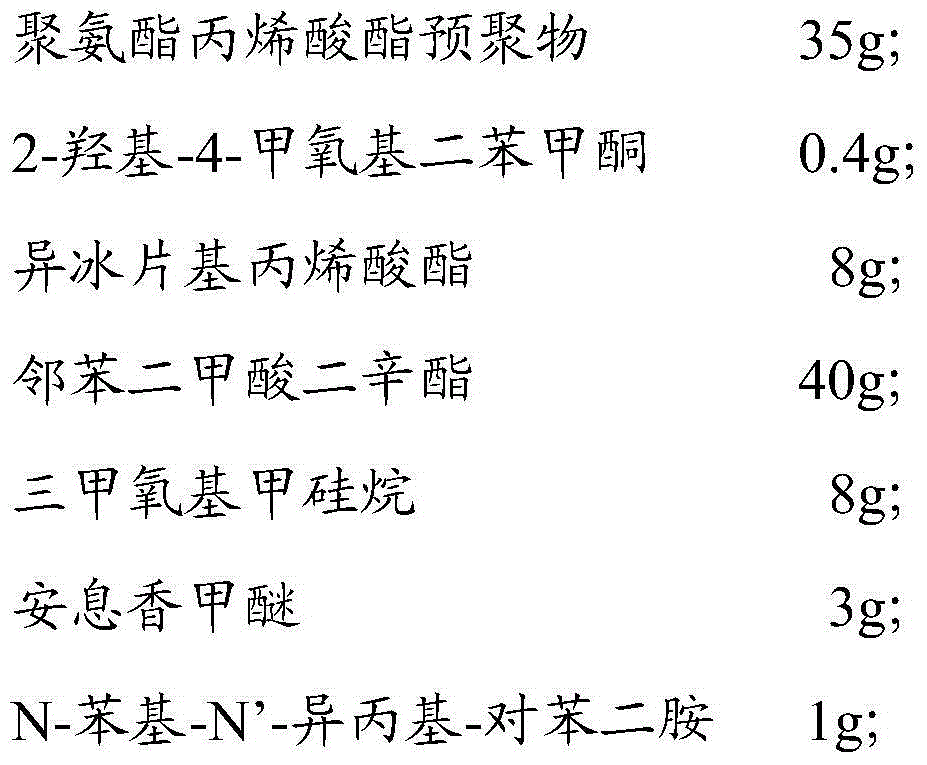

[0035] An optical glue comprising

[0036]

[0037] Prepared as follows:

[0038] (1) Preparation of polyurethane acrylate prepolymer

[0039] Add in the flask: heat 129g (0.0645mol) polytetrahydrofuran diol (molecular weight 2000, PTMGE-2000, BASF), 108g (0.036mol) polycaprolactone diol (molecular weight 3000, Daicel, Japan) to 115°C , vacuum dehydration for 2 hours, adopt Karl Fischer method to measure moisture content to be below 0.05%, add 0.095g (0.00015mol) dibutyltin dilaurate as catalyst, be warming up to 115 ℃, drop 45g (0.18mol) 2, 2-Diphenylmethane diisocyanate, stirred for 5 hours, then added 15.1g (0.18mol) methacrylate, 0.35g (0.000554mol) dibutyltin dilaurate, 0.18g (0.0008mol) 2-hydroxy-4 -Methoxybenzophenone, reacted at 90°C for 8 hours. After the reaction was completed, the isocyanate was measured at 2270cm by infrared spectroscopy. -1 The stretching vibration front at the position drops to the same, that is, the isocyanate group reacts completely, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com