Ink

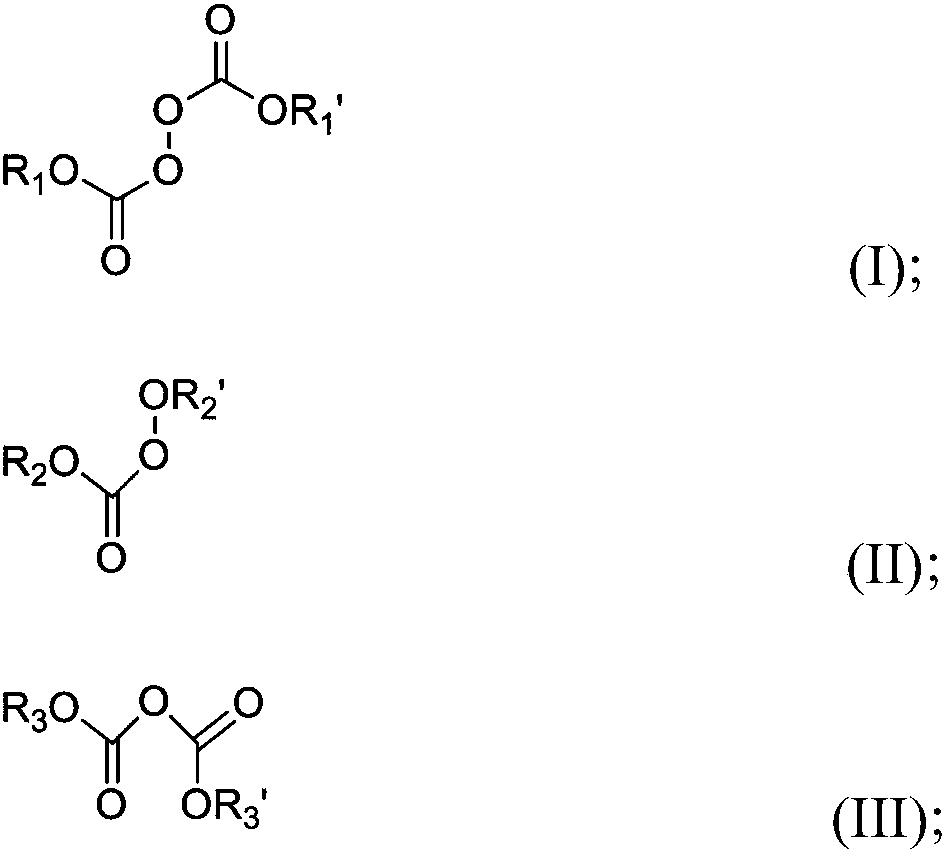

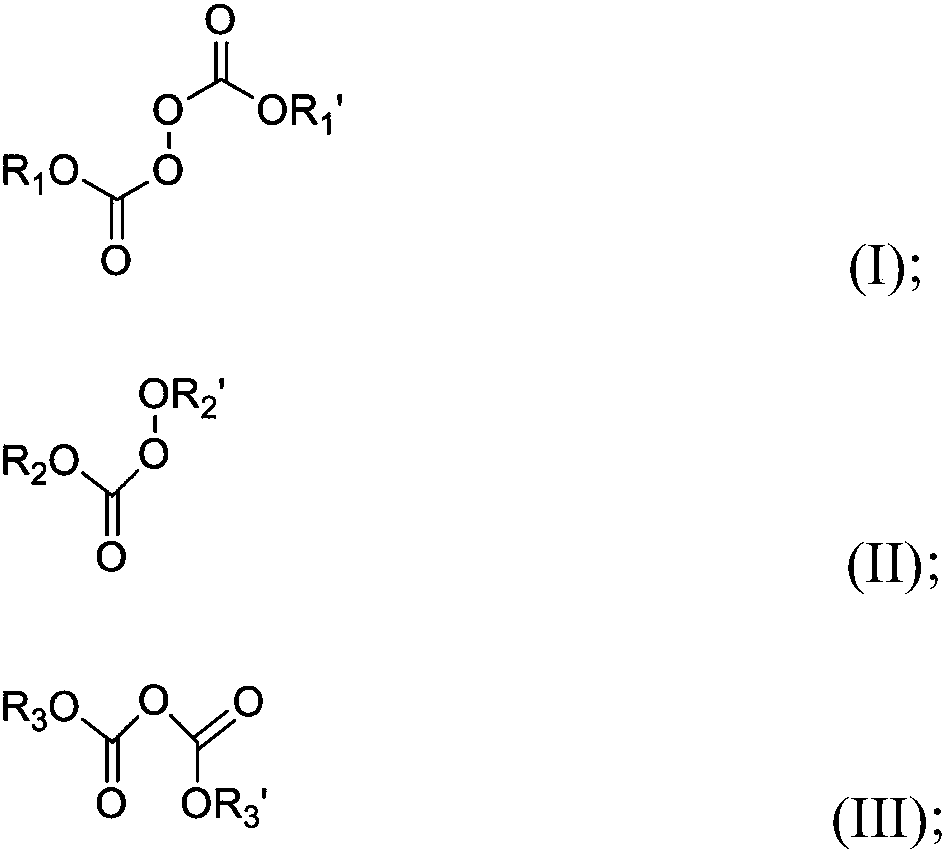

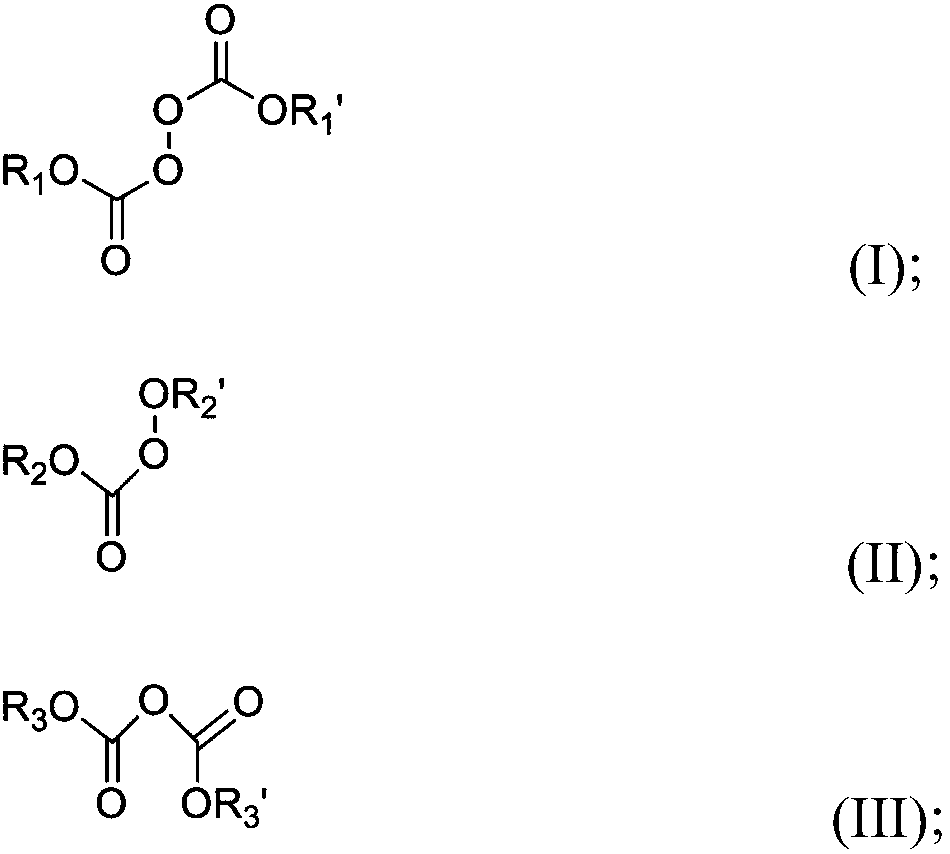

A technology of ink and percarbonic acid, which is applied in the direction of ink, household utensils, applications, etc., can solve the problems of low boiling point, poor dispersibility, and low viscosity of printing ink, etc., and achieve the effect of lowering threshold voltage, good dispersion performance, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] Based on the above-mentioned printing ink, the present invention also provides a preparation method of the printing ink, comprising the steps of: first dispersing the inorganic nanomaterial in a solvent containing at least one percarbonate organic solvent according to the above-mentioned formula, and then stirring evenly, Printing ink with proper viscosity and surface tension can be obtained. Control the boiling point of all ink compositions below 320°C.

[0052] The present invention also provides a method for carrying out inkjet printing with the printing ink, which comprises the steps of:

[0053] Inorganic nanomaterial layer printing: choose a suitable inkjet printer to inkjet print the inorganic nanomaterial layer.

[0054] Post-treatment: Under the action of heating or cooling and / or decompression, remove the percarbonate organic solvent in the inorganic nanomaterial layer, except for inorganic nanomaterials (quantum dots), so that other organic substances in the...

Embodiment 1

[0061] The mixed solvent is composed of 1-methoxynaphthalene, dipentylbenzene and bis(2-ethylhexyl)peroxydicarbonate, and all solvents are purified by corresponding methods to remove water and oxygen to a purity greater than 99.9%.

[0062] Add the following components to about 500mL single-necked flask, under stirring, the order of addition is: 10wt% oleylamine-stabilized red CdSe / ZnS quantum dots, 5wt% 1-methoxynaphthalene, 5wt% dipentyl Benzene, 80 wt% bis(2-ethylhexyl) peroxydicarbonate, and the mixture was stirred for 30 minutes to obtain printing ink.

[0063] The printing ink is injected into the printing inkjet printer cartridge, the corresponding parameters are adjusted, and the red quantum dot layer of 20×30um and resolution 200×200ppi is printed.

[0064] Place the printed substrate on a hot stage and heat it to 155°C with a vacuum of 1×10 -6 Volatilize and dry under Torr for 30 minutes to obtain a monochromatic quantum dot light-emitting layer.

Embodiment 2

[0066] The mixed solvent is composed of tridecane, tetrahydronaphthalene and tert-butylperoxyisopropyl formate, and all solvents are purified by corresponding methods to remove water and oxygen to a purity greater than 99.9%.

[0067] Add the following components to an approximately 500mL high-density polyethylene bottle with stirring in the following order: 10wt% oleylamine-stabilized green CdZnSe / CdZnS, 20wt% tridecane, 30wt% tetralin, 40wt% % tert-butylperoxyisopropyl formate, the mixture was stirred for 30 minutes to obtain printing ink.

[0068] With an inkjet printer, it is printed into a green quantum dot layer of 20×30um and a resolution of 200×200ppi.

[0069] Heat to 150°C on a hot plate, vacuum 1×10 -5 Volatilize and dry under Torr for 30 minutes to obtain a monochromatic quantum dot light-emitting layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com