Penetrating glue applied to pipeline repair, and preparation method thereof

A pipeline repair and modification technology, which is applied in the field of penetrating glue, can solve the problems that the fluidity effect of penetrating glue cannot be satisfied, and achieve the effect of good viscosity, good fluidity and good cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

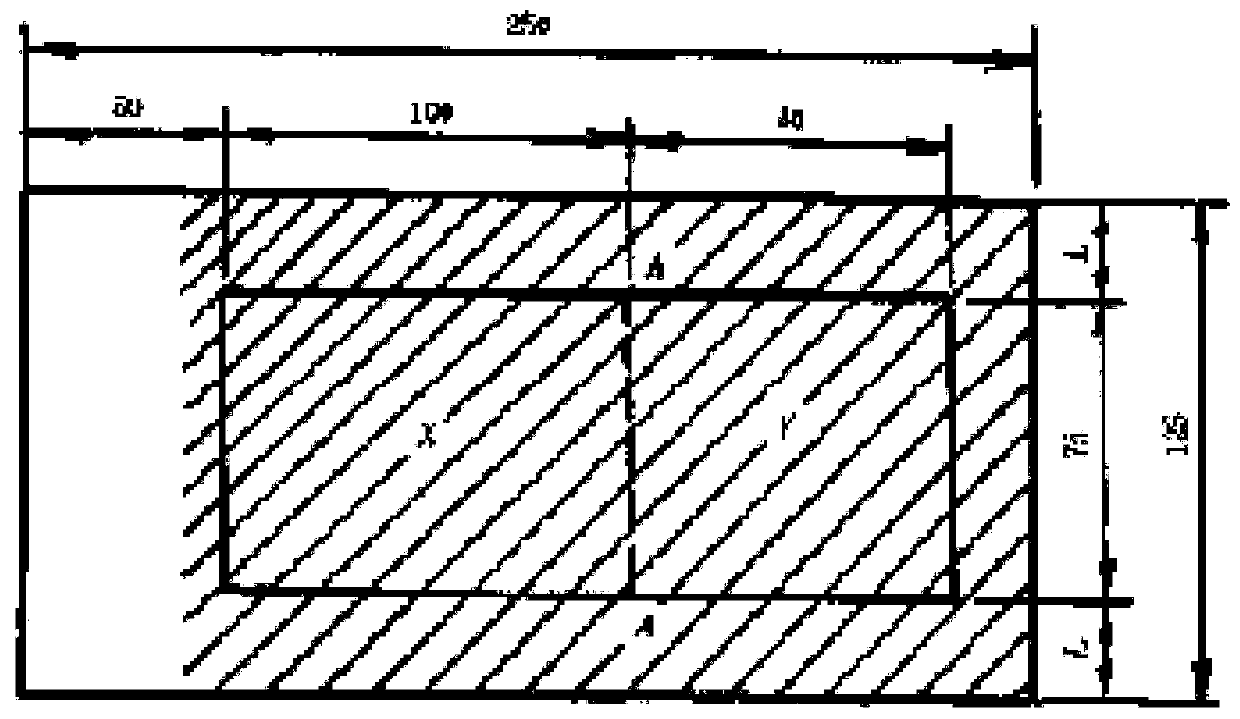

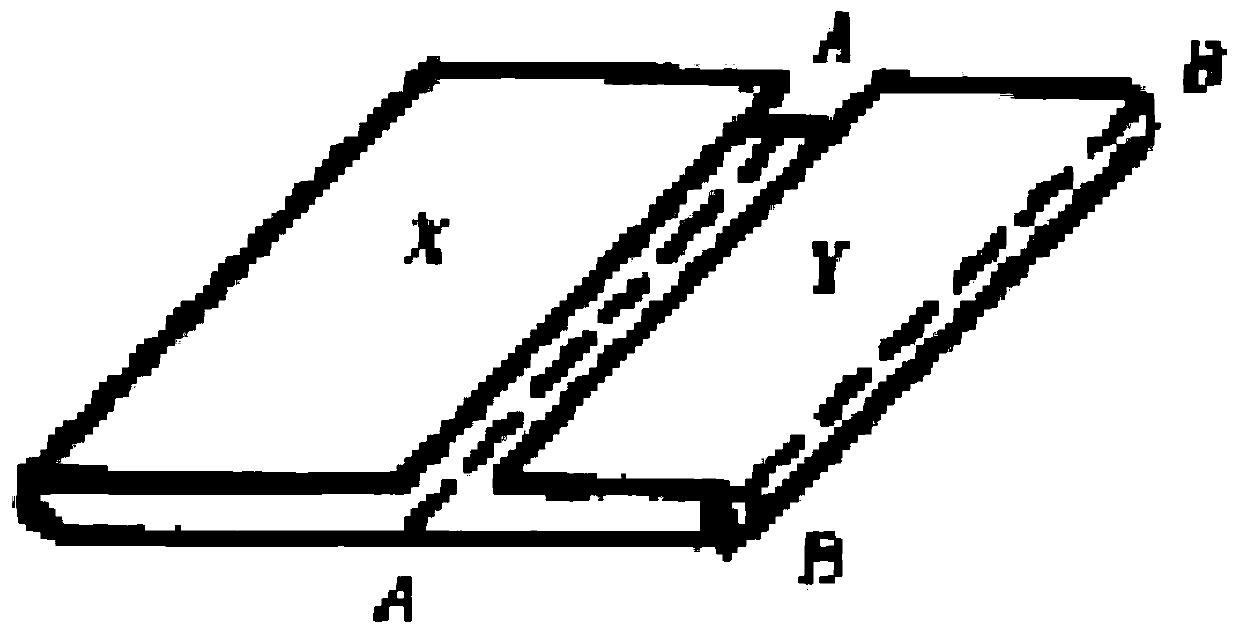

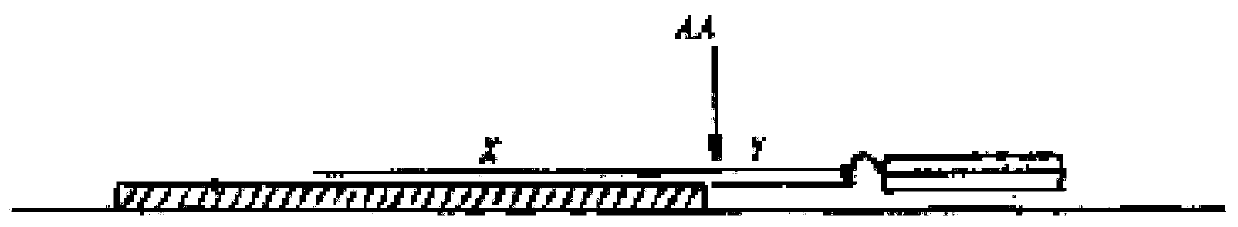

Image

Examples

preparation example Construction

[0029] The present invention also proposes a preparation method of permeable glue applied to pipeline repair, comprising the following steps:

[0030] S1. Mix polyether and silicate resin evenly, heat up to 110-130°C, keep warm for 20-40min, then add plasticizer TXIB and catalyst and mix evenly, continue to heat up to 140-150°C, keep warm for 30-50min, then Stir at a speed of 650-850r / min for 1-2h to obtain material I;

[0031] S2. Add silane coupling agent KH-570, modified tackifier and waterproof modified additive to material I, mix evenly, heat up to 120-130°C, keep warm for 20-40min, and stir at 1500-2500r / min for 5 -10h, cooled to room temperature to obtain penetrating glue for pipeline repair.

Embodiment 1

[0033] A penetrating glue for pipeline repair, its raw materials include by weight: 100 parts of polyether, 5 parts of plasticizer TXIB, 6 parts of catalyst, 6.5 parts of silicate resin, 6 parts of diluent, silane coupling agent KH 4 parts of -570, 15 parts of modified tackifier, 12 parts of waterproof modified auxiliary agent.

[0034] The modified tackifier is prepared according to the following process:

[0035] S1. Grind 30 parts of wood ammonium to 80 meshes by weight, then add 12 parts of phenolic resin, 6 parts of phenol and 7.5 parts of concentrated sulfuric acid solution with a mass fraction of 95% and mix evenly, heat up to 100°C, keep it warm for 25min, and then heat it at 750r Stir at a speed of 1 / min for 250 minutes, then add 4 parts of formaldehyde and mix evenly, raise the temperature to 135°C, keep the temperature for 15 minutes, and obtain material a;

[0036] S2. Mix 3 parts of ethanol solution with mass fraction of 95%, 6 parts of cornstarch and 6 parts of ...

Embodiment 2

[0043] A penetrating glue used in pipeline repair, its raw materials include by weight: 80 parts of polyether, 8 parts of plasticizer TXIB, 3 parts of catalyst, 9 parts of silicate resin, 4 parts of diluent, silane coupling agent KH 6 parts of -570, 10 parts of modified tackifier, 16 parts of waterproof modified auxiliary agent.

[0044] The modified tackifier is prepared according to the following process:

[0045] S1. Grind 20 parts of wood ammonium to 100 meshes by weight, then add 8 parts of phenolic resin, 8 parts of phenol and 6 parts of concentrated sulfuric acid solution with a mass fraction of 95% and mix evenly, heat up to 120 ° C, keep it warm for 20 minutes, and then heat it at 850 r Stir at a speed of 1 / min for 20 minutes, then add 6 parts of formaldehyde and mix evenly, raise the temperature to 130°C, keep the temperature for 20 minutes, and obtain material a;

[0046] S2, 1 part of ethanol solution with a mass fraction of 95%, 8 parts of cornstarch and 3 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com