Floating type CoFe2O4/TiO2/floating bead composite photocatalyst and preparation method thereof

A photocatalyst and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst carrier, etc., can solve the problem of ineffective use of visible light, low photocatalyst quantum efficiency, and limited industrial application and other issues, to achieve easy recycling and reuse, improve photocatalytic degradation effect, increase surface area and adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

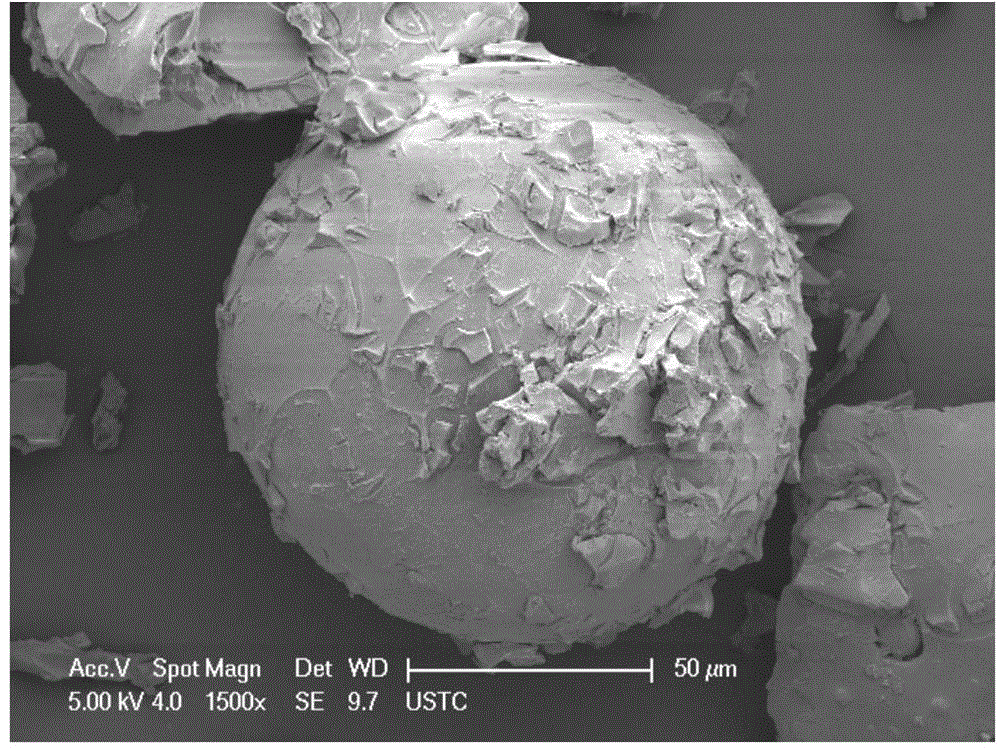

[0028] A floating CoFe 2 o 4 / TiO 2 / floating bead composite photocatalyst, each component by weight percentage is: Co is 0.7wt%, Fe is 1.5wt%, Ti is 15wt%, and the rest is fly ash floating bead catalyst carrier.

[0029] The above-mentioned floating CoFe 2 o 4 / TiO 2 / The preparation method of floating bead composite photocatalyst, comprises the steps:

[0030] 1) Pretreatment of floating beads

[0031] Prepare 10% dilute nitric acid, soak the fly ash floating beads in it for 15 hours, filter, rinse with deionized water until neutral, then dry it, then put it in a muffle furnace, and calcinate it at 400°C for 2 hours to remove the unremoved Carbonization of organic matter. Rinse with distilled water to sort out the floating beads that are completely floating on the water surface. After filtering, drying and sieving, select the floating beads with a particle size of 100-125um as the carrier of the catalyst;

[0032] 2) TiO 2 Sol preparation

[0033] Add 40mL of butyl...

Embodiment 2

[0042] A floating CoFe 2 o 4 / TiO 2 / floating bead composite photocatalyst, each component by weight percentage is: Co is 0.5wt%, Fe is 2wt%, Ti is 18wt%, and the rest is fly ash floating bead catalyst carrier.

[0043] Its preparation method is with embodiment 1.

Embodiment 3

[0045] A floating CoFe 2 o 4 / TiO 2 / floating bead composite photocatalyst, each component by weight percentage is: Co is 1wt%, Fe is 1wt%, Ti is 12wt%, and the rest is fly ash floating bead catalyst carrier.

[0046] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com