Four-roll calendering and draping production device for PVC plastic floor surface film attachment

A technology of stone-plastic flooring and four-roll calendering, which is applied to lamination devices, lamination, and layered products, etc., can solve the problems of difficult air discharge, no adhesion fastness, affecting surface quality and adhesion fastness, etc. Achieve the effect of easy combination, convenient and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention are described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0020] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

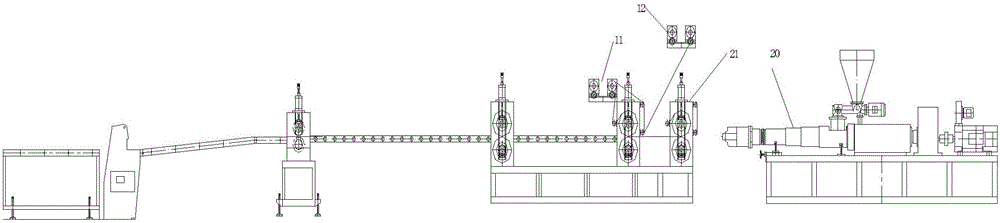

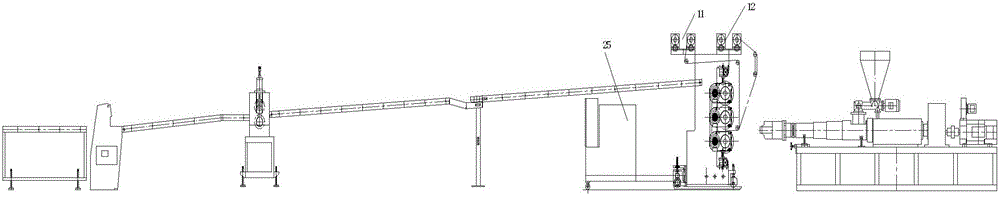

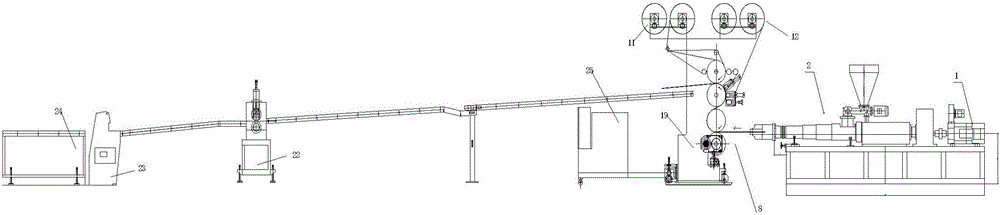

[0021] see Figure 3-4 , in the patent embodiment of the present invention, the four-roll calender laminating production device for PVC stone-plastic floor surface film includes a four-roll calender 8, a wear-resistant film unwinding mechanism 11, a printing film unwinding mechanism 12, and a wear-resistant film laminating mechanism 13. The printing film bonding mechanism 14 and the exporting mechanism 18 also include a twin-screw extruder 2, a motor 1, a temperature control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com