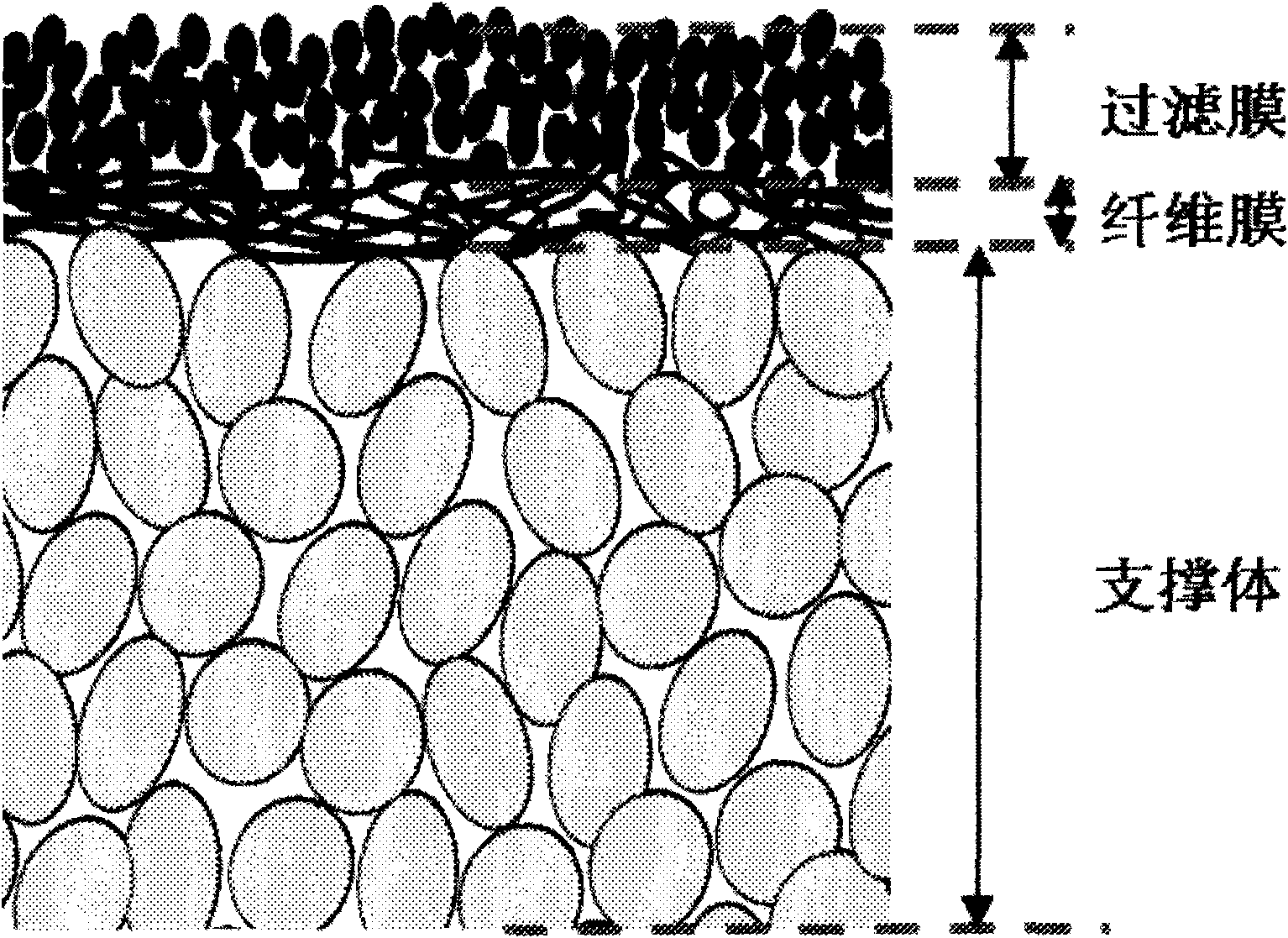

Double-layer asymmetrical surface film of porous ceramic filter tube for dust filter and preparation method thereof

A technology for porous ceramics and dust filtration, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of reducing filtration pressure drop, reducing surface film thickness, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

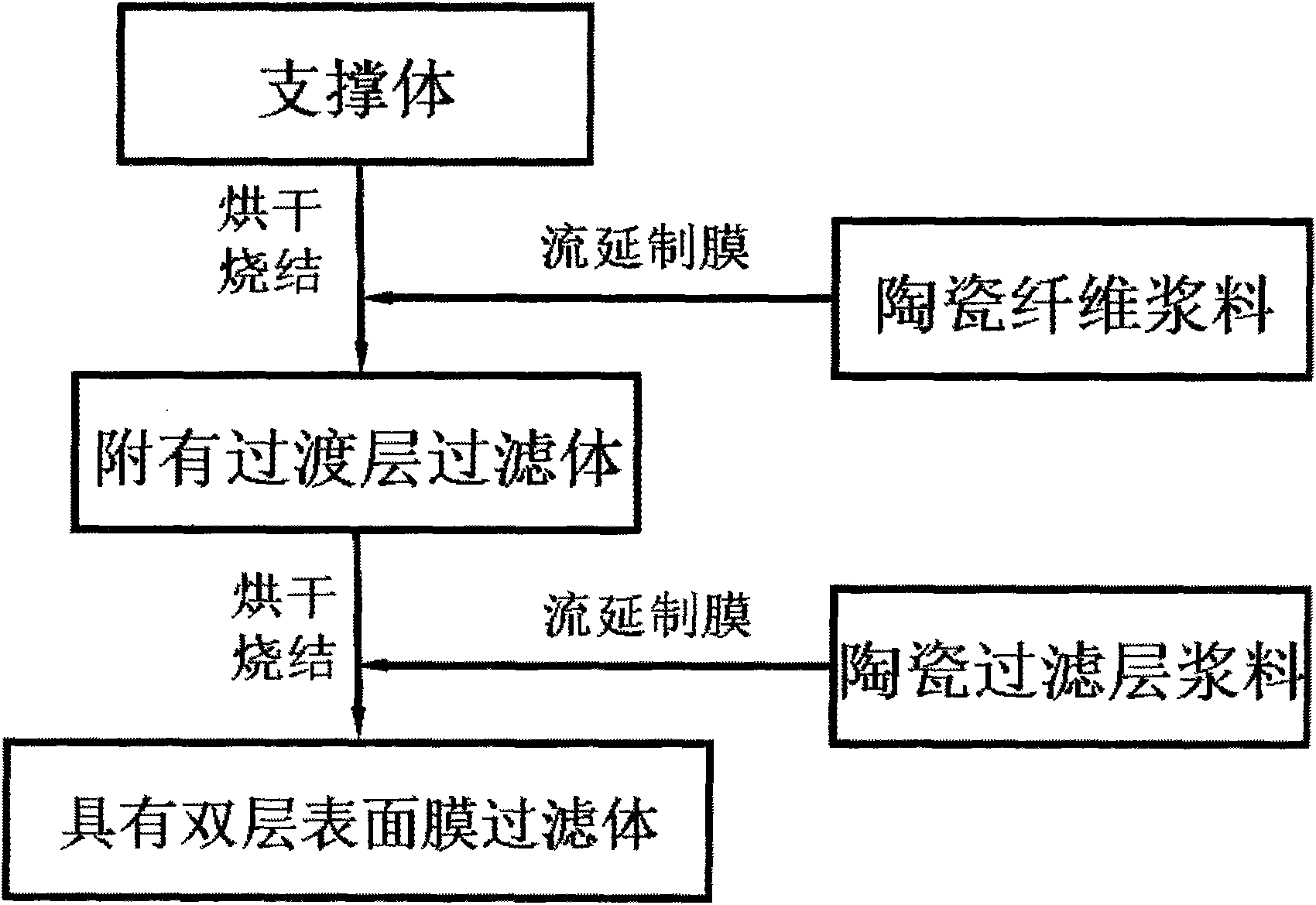

[0031] (1) First prepare the ceramic fiber slurry; add the ceramic fiber and dispersant to a certain solvent, heat the solvent and keep stirring the mixed solution until the ceramic fiber is evenly dispersed;

[0032] (2) The ceramic fiber slurry with good dispersibility prepared in step 1 is coated on the porous ceramic support by a suitable film-making method to form a ceramic fiber blank film with a complete surface and uniform film thickness of a certain thickness, and It is dried at a certain temperature;

[0033] (3) Prepare the slurry of the filter membrane; select ceramic powder and binder with a specific average particle size, disperse it in a specific solvent, and finally form a filter membrane slurry with well-dispersed solid particles and suitable viscosity;

[0034] (4) The slurry prepared in step 3 is formed on the ceramic fiber blank membrane with a suitable thickness and good integrity of the filter membrane blank membrane by a suitable membrane-making method, ...

Embodiment 1

[0047] First, add 2g of mullite fiber with a diameter distribution of 1μm to 500μm and an aspect ratio greater than 10 and 1.5g of sodium carboxymethylcellulose into a beaker, then add a sufficient amount of water, heat to boil and stir at the same time until the mullite The fibers are uniformly dispersed and the mullite fiber mass fraction reaches 5%, and the fiber film slurry is obtained. In addition, 9 g of silicon carbide powder with a particle size of 54 μm and 1 g of kaolin were magnetically stirred and mixed in 35 ml of deionized water to obtain filter membrane slurry.

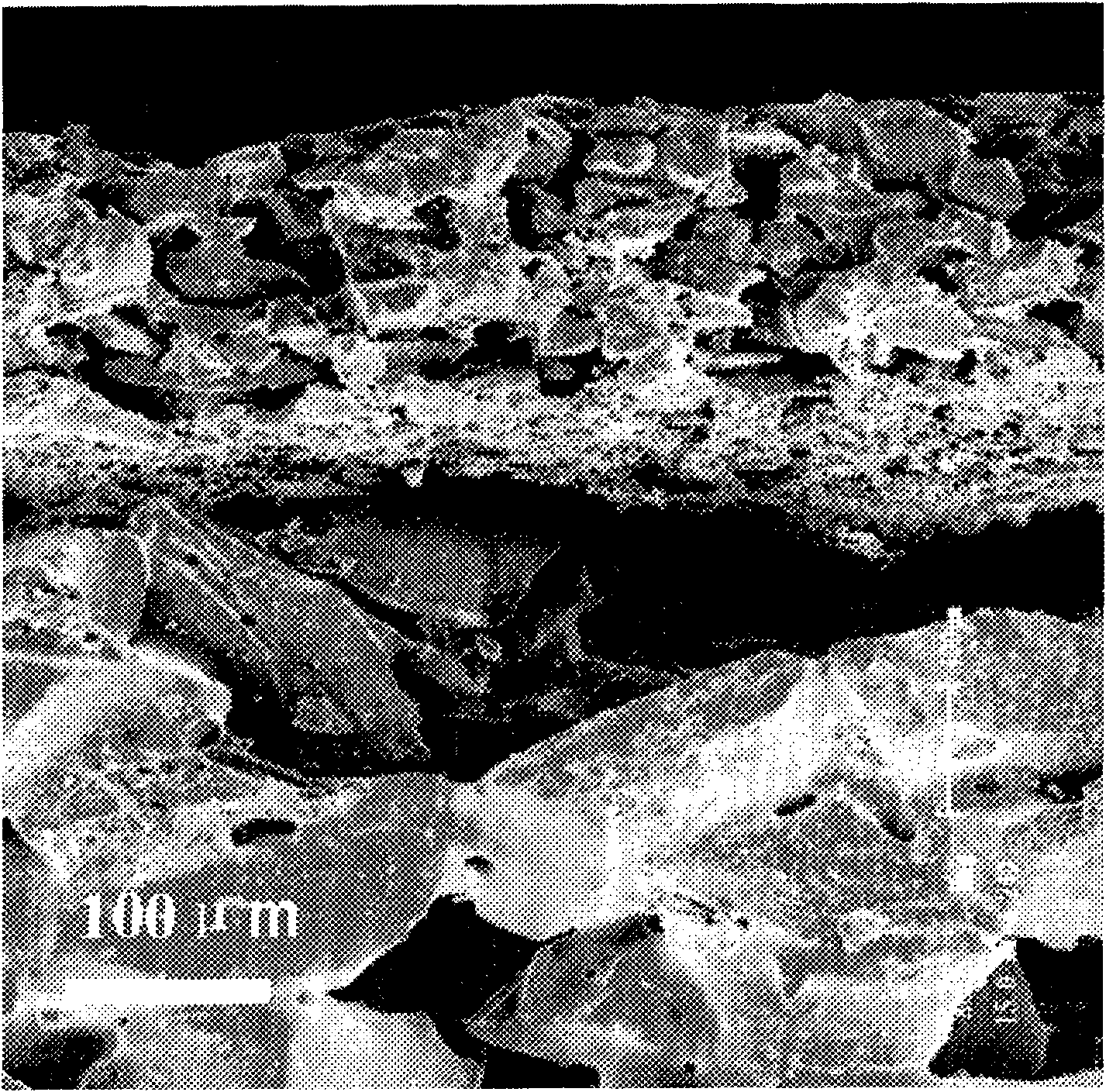

[0048] The obtained mullite fiber slurry was cast on a silicon carbide support sheet to prepare a fiber blank film, and the fiber blank film was dried at 110°C. Then, a filter membrane is prepared on the mullite fiber blank membrane by casting method, which is also dried at 110°C. Finally, the porous ceramic with double-layer asymmetric surface membrane was sintered at 1280°C for 3h.

[0049] The prep...

Embodiment 2

[0052] First, add 1g of mullite fibers with a diameter distribution of 1 μm to 500 μm and an aspect ratio greater than 10, 1 g of aluminum silicate fibers with a diameter distribution of 1 μm to 500 μm and an aspect ratio greater than 10, and 2 g of polyvinyl alcohol into a beaker, and then add A sufficient amount of water is heated and boiled while stirring until the mullite fibers are uniformly dispersed and the mass fraction of the mullite fibers reaches 10%, to obtain a fiber film slurry. In addition, 9 g of mullite powder with a particle size of 20 μm and 1 g of kaolin were magnetically stirred and mixed in 35 ml of deionized water to obtain filter membrane slurry.

[0053] The prepared mixed slurry of mullite fiber and aluminum silicate fiber was cast on a silicon carbide support sheet to prepare a fiber blank film, and the fiber blank film was dried at 110°C. Then, a filter membrane is prepared on the mullite fiber blank membrane by casting method, which is also dried a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com