Backlight source assembly

A technology of backlight source and components, applied in optics, nonlinear optics, instruments, etc., can solve the problems of increased external size, increased material cost of the fixing frame 12, inconvenient to replace the lamp board, etc., to increase the heat dissipation effect and stabilize the positioning. with limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

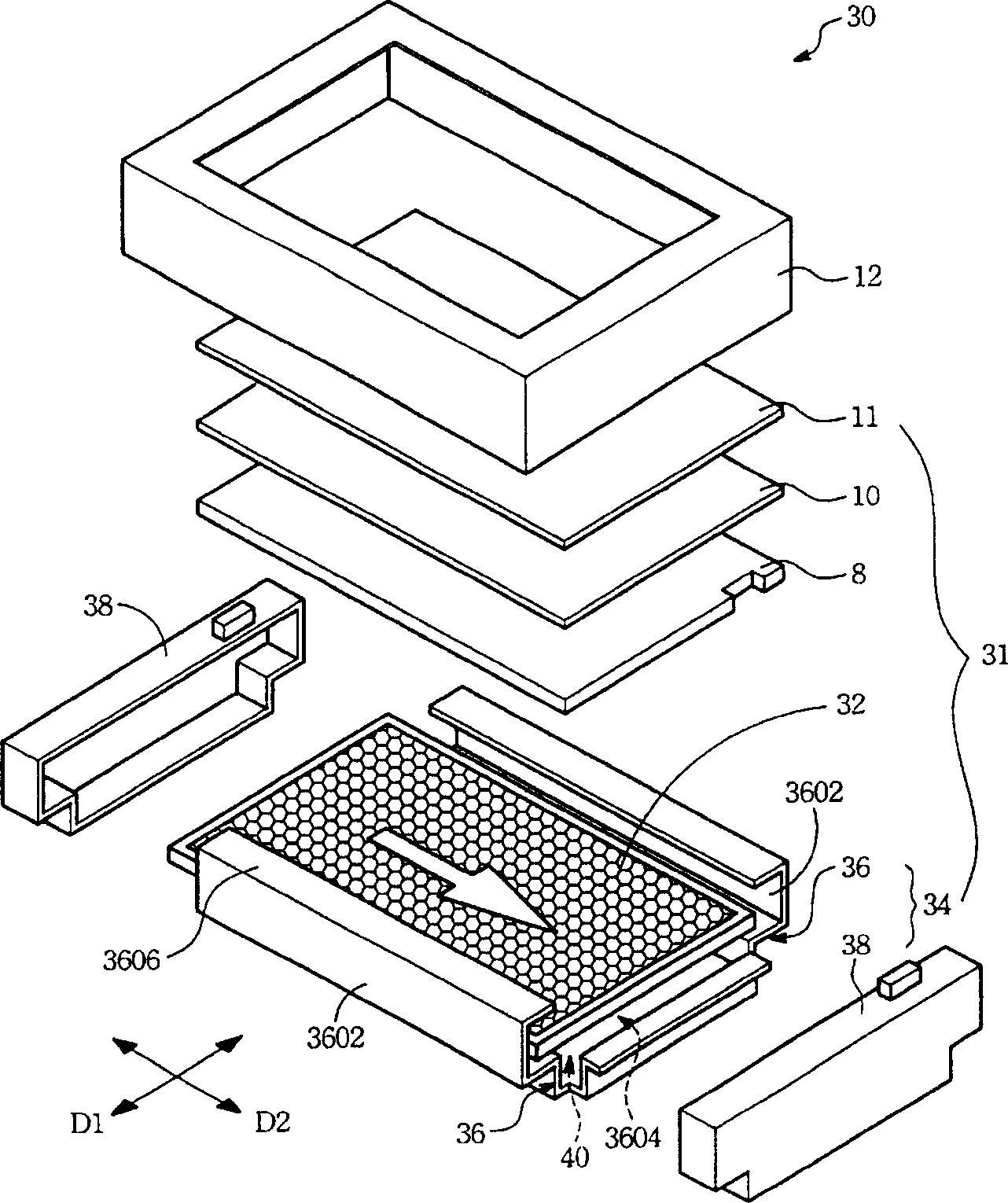

[0045] Refer to figure 2 . The present invention relates to a light board fixing device 34. The light board fixing device is used in a backlight assembly 31 to fix a light board 32. The light board fixing device 34 includes a light board base 36 and at least one limiter. Bit border 38.

[0046] The light board base 36 is arranged on the bottom surface of the light board 32. At least two opposite sides of the light board base 36 extend upward to form a side frame 3602, which is used to limit the light to the first direction D1 of the two-dimensional space of the light board 32. Plate 32, side frame 3602 and then horizontally extend the covering edge 3606 inward for the diffusion plate 8 and the optical material 10 to carry. The width of the covering edge 3606 can be set according to the width of the non-light emitting area 32A of the light board 32 to effectively shield No light-emitting area 32A.

[0047] The limiting frame 38 is sleeved on the side of the open end 3604 of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com