Riveting device for L-shaped leaf springs of travel switch cores

A travel switch and riveting device technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve problems such as easy loosening of rivets, affecting riveting effect, and easy change of reed position, so as to ensure riveting effect, simple structure, and firm positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

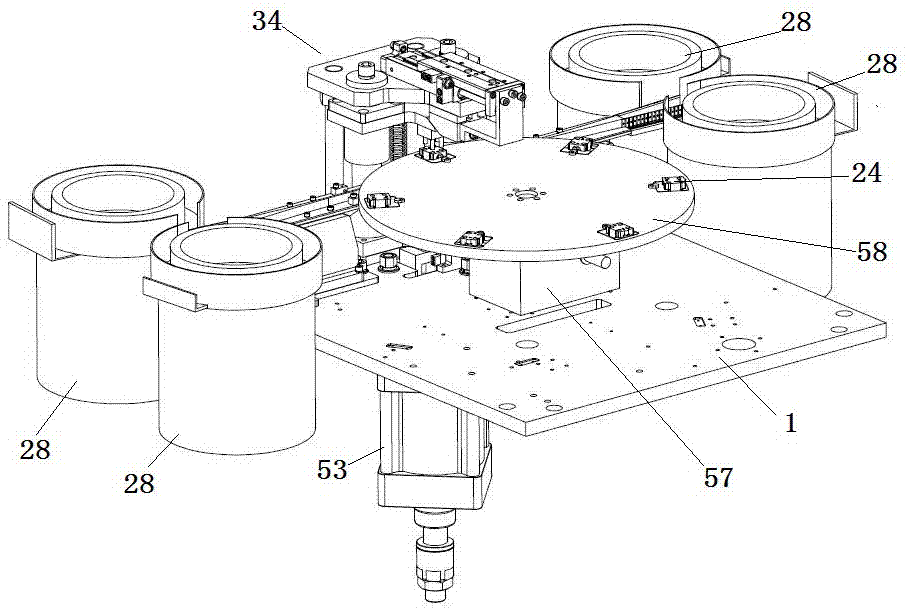

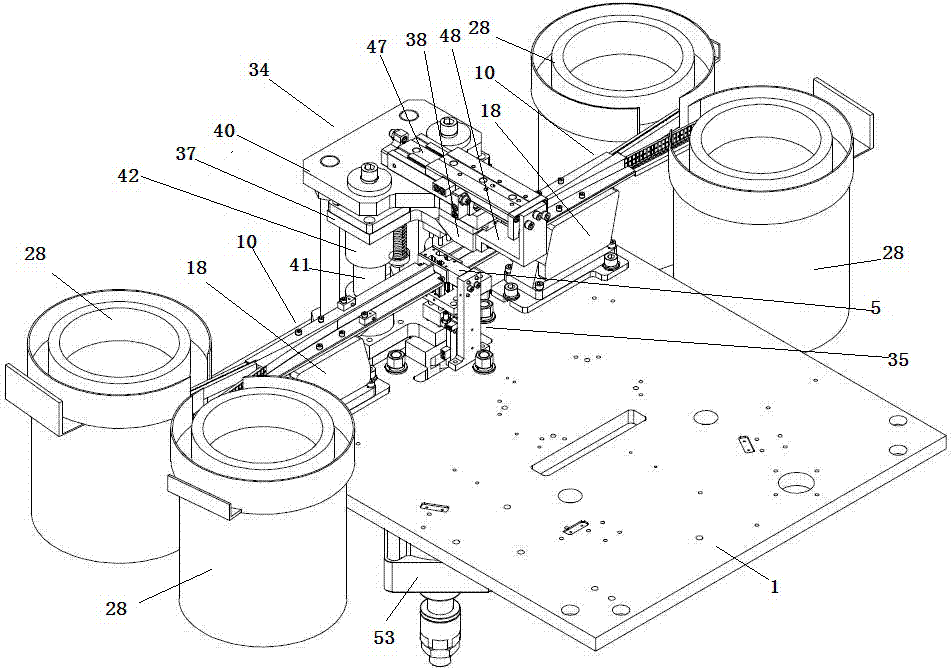

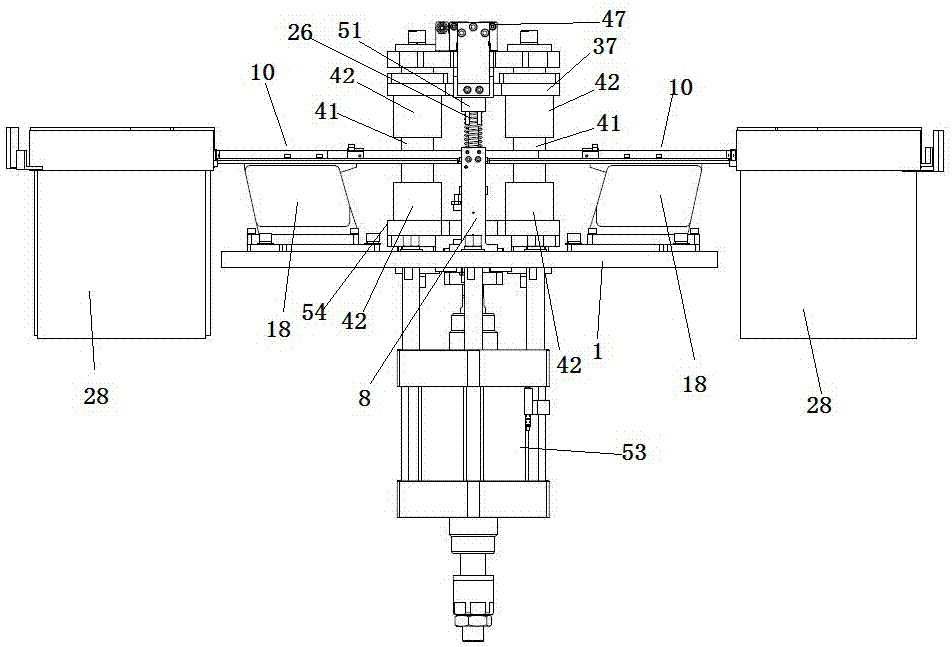

[0039] like Figure 1-22As shown, a riveting device for the L-shaped reed of the travel switch core, including a working table 1, a positioning block 5 is fixed above the working table, and a motor and a cam are arranged above the positioning block. The device 57 drives the rotating circular turntable 58, and the surface circumference of the said circular turntable is evenly distributed with a plurality of receiving seats 30 for placing the travel switches to be riveted, and said receiving seats are provided with a socket for connecting with the inside of the travel switch. The vertical give way groove 31 that the rivet communicates, the vertical guide groove 6 that communicates with the vertical give way groove is opened on the described positioning block, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com