Rail wagon bogie single-stage shaft housing hanging and positioning device

A technology for railway wagons and positioning devices, which is applied in the direction of the device for lateral relative movement between the chassis and the bogie, the installation of the axle box, etc., which can solve problems such as increased cost and structural complexity, detection, missing detection, etc., to avoid heat Shaft failure, ensuring safety, and reducing wheel and rail wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

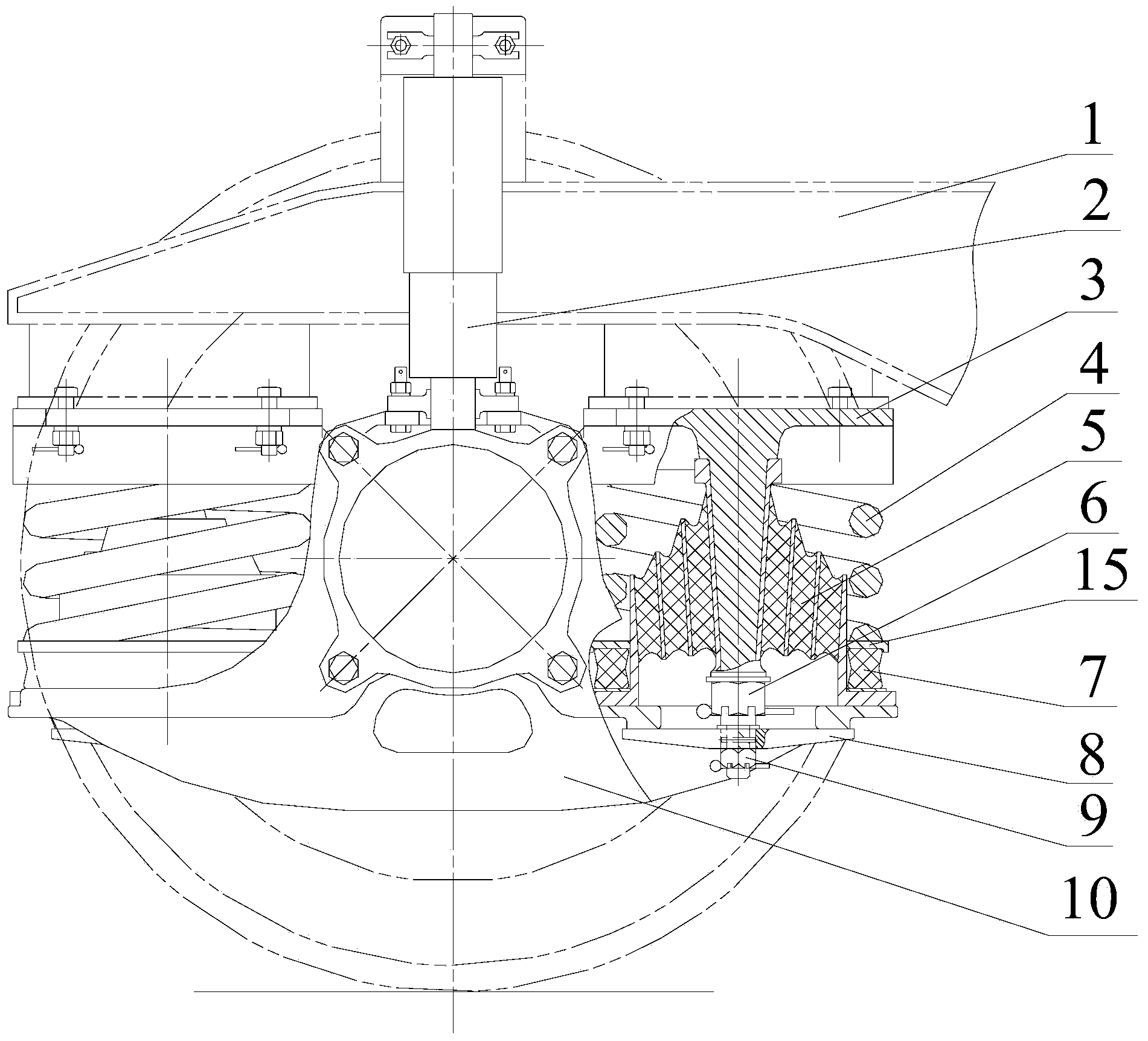

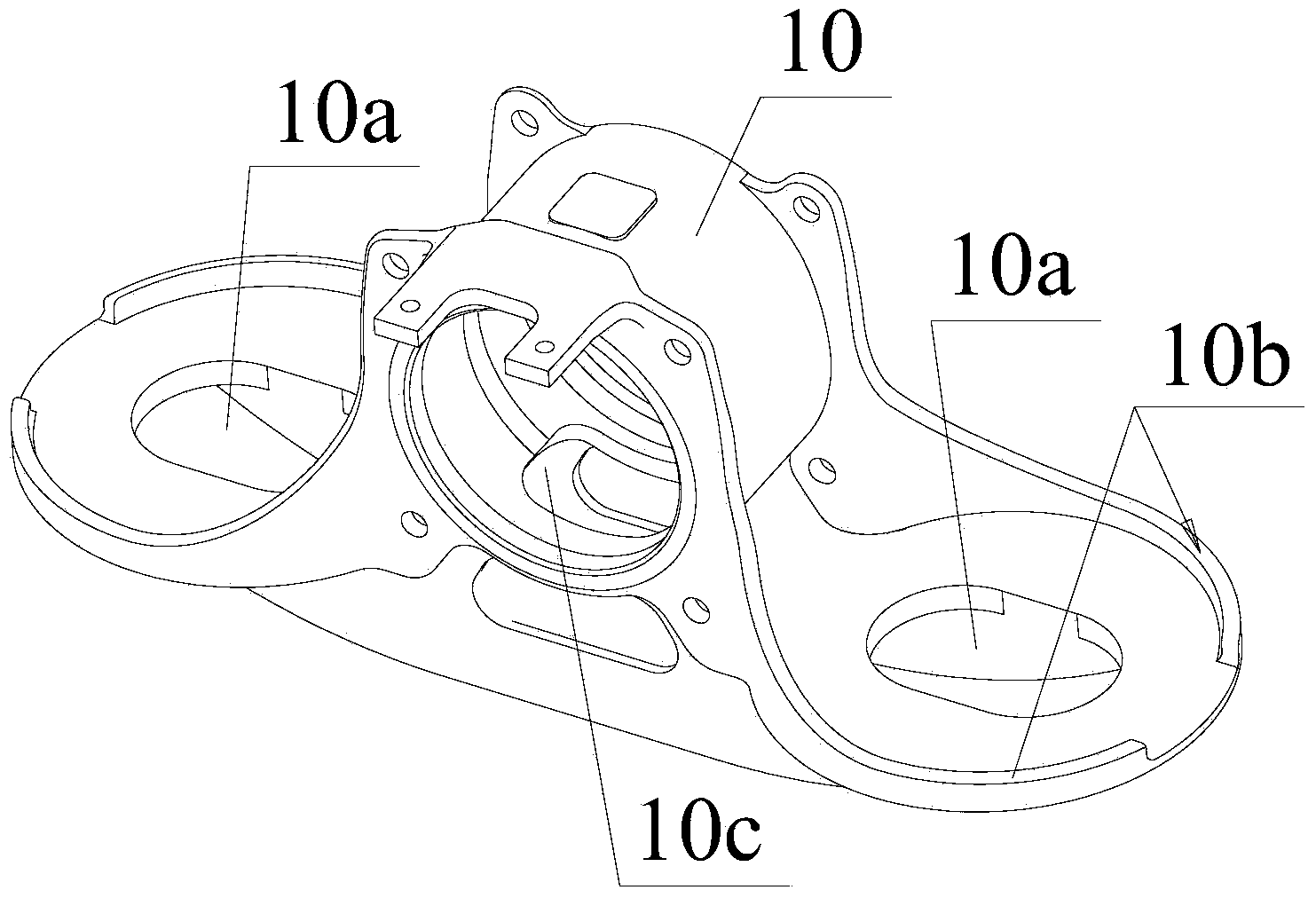

[0023] Such as figure 1 The shown railway freight car bogie axle box suspension positioning device includes the axle box 10, the vertical hydraulic shock absorber 2 arranged between the top of the axle box 10 and the side frame of the frame composition 1, and the vertical hydraulic shock absorber 2 arranged on the two sides of the axle box 10. The spring guide column 3 between the top of the side spring cap and the bottom of the frame composition 1, the steel round spring 4 and the rubber stack locator 5, and the lifting stopper 8 arranged under the spring cap on both sides of the axle box 10. The vertical hydraulic shock absorber 2 in this embodiment adopts a two-stage or multi-stage variable damping shock absorber.

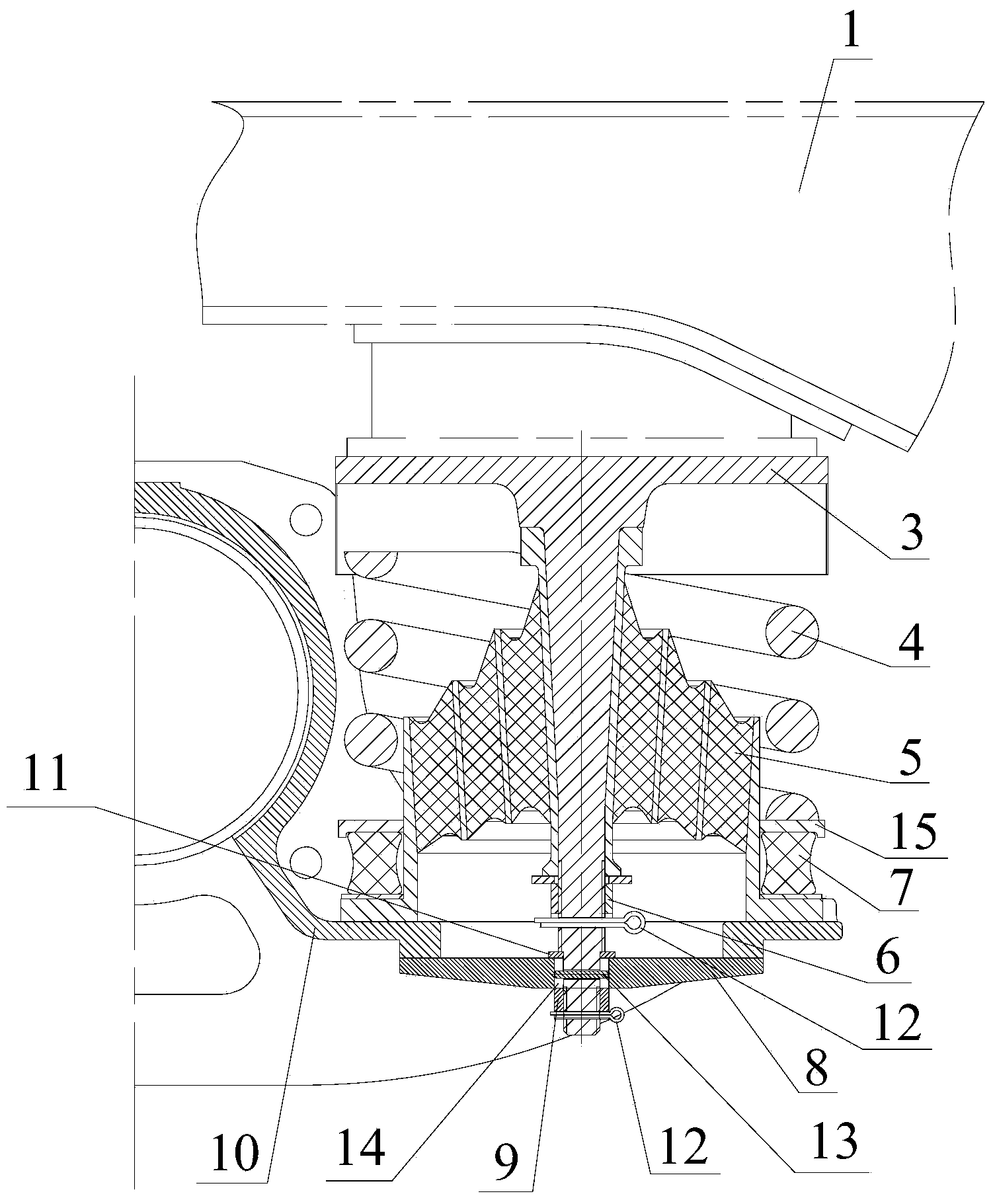

[0024] combine figure 2 As shown, the upper end plane of the spring guide column 3 is fixedly connected with the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com