Electromagnetic valve

A solenoid valve and magnetic technology, applied in the field of solenoid valves, can solve problems such as cost increase, and achieve the effect of correct positioning and stable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the solenoid valve according to the present invention will be described in detail with reference to the drawings.

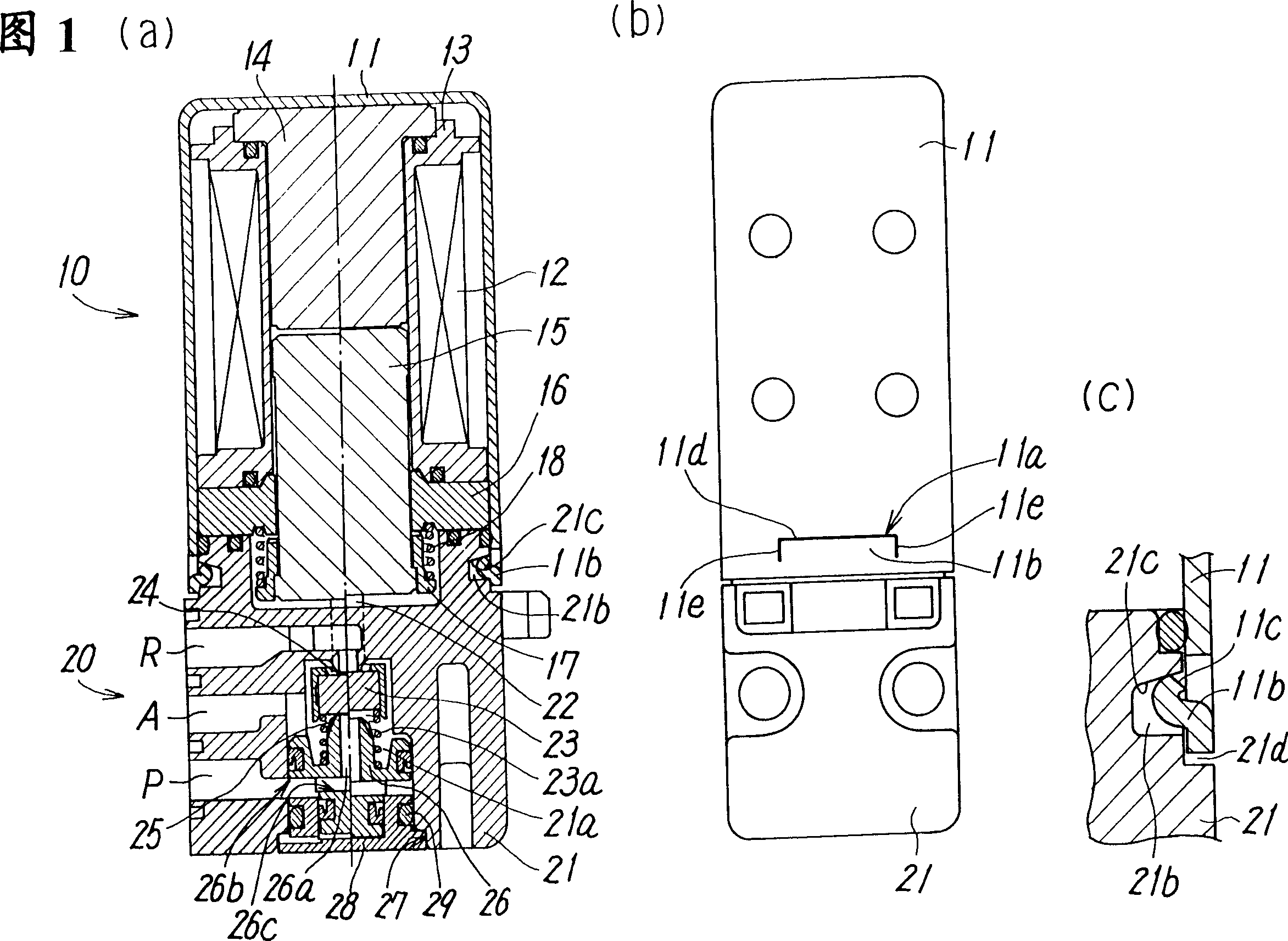

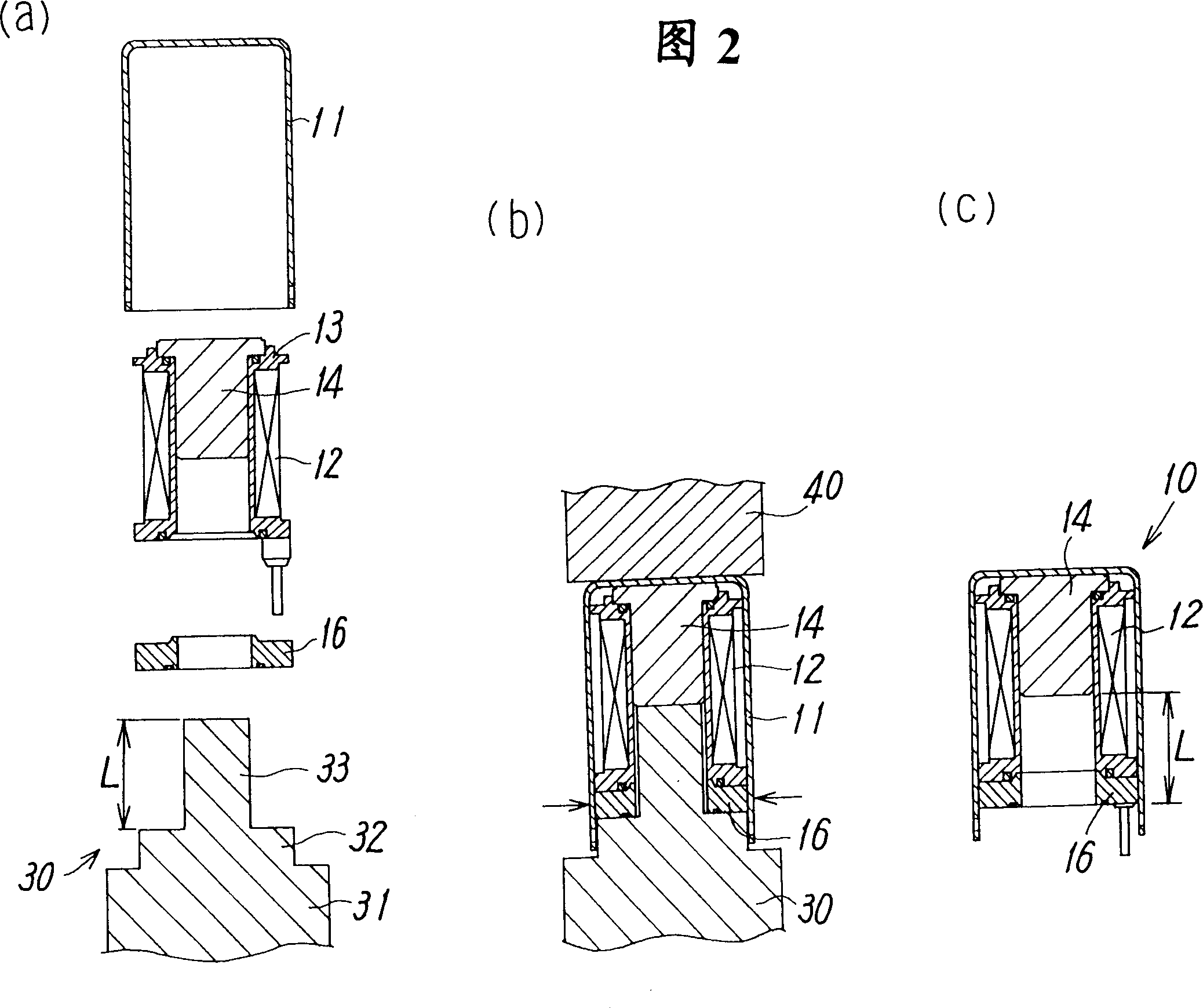

[0019] The solenoid valve shown in FIGS. 1( a ) to ( c ) is a solenoid valve according to the first embodiment, and includes a solenoid unit 10 and a valve unit 20 .

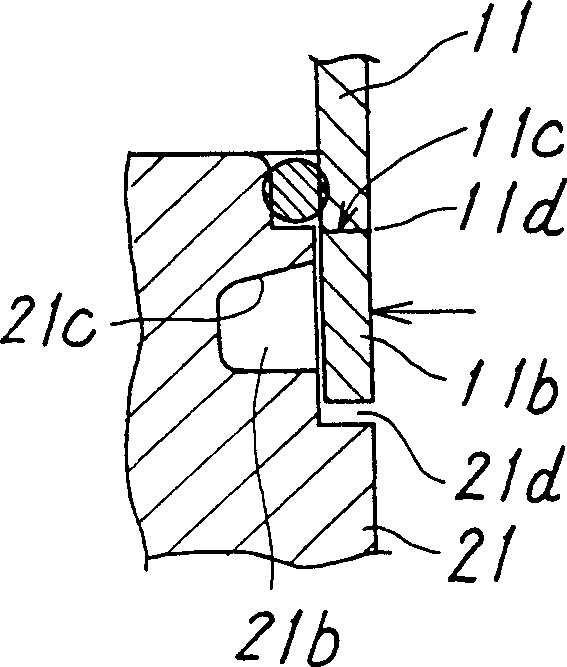

[0020] The solenoid part 10 is formed by a bobbin 13 on which a coil 12 is wound, a side wall having a substantially rectangular cross-section provided around the coil 12, and a segment end wall integrally formed with the side wall. : a magnetic box 11 with an opening at one end; a magnetic plate 16 disposed on one side of the opening of the above-mentioned magnetic box 11 in the above-mentioned bobbin 13; The central hole of the plate 16 and the coil frame 13 is slidably embedded with the inserted moving iron core 15 from one side of the magnetic plate 16; While being fitted and inserted into the center hole of the bobbin 13, the fixed iron core 14 (fixed magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com