Screen printing device in automatic round-surface screen printing machine

A technology of screen printing device and screen printing machine, which is applied in the field of machinery, can solve problems such as the difficulty of grasping the time difference between successive actions, increasing the difficulty of manufacturing, and the complicated structure of the screen printing machine, so as to achieve the effects of fast printing speed, firm positioning, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

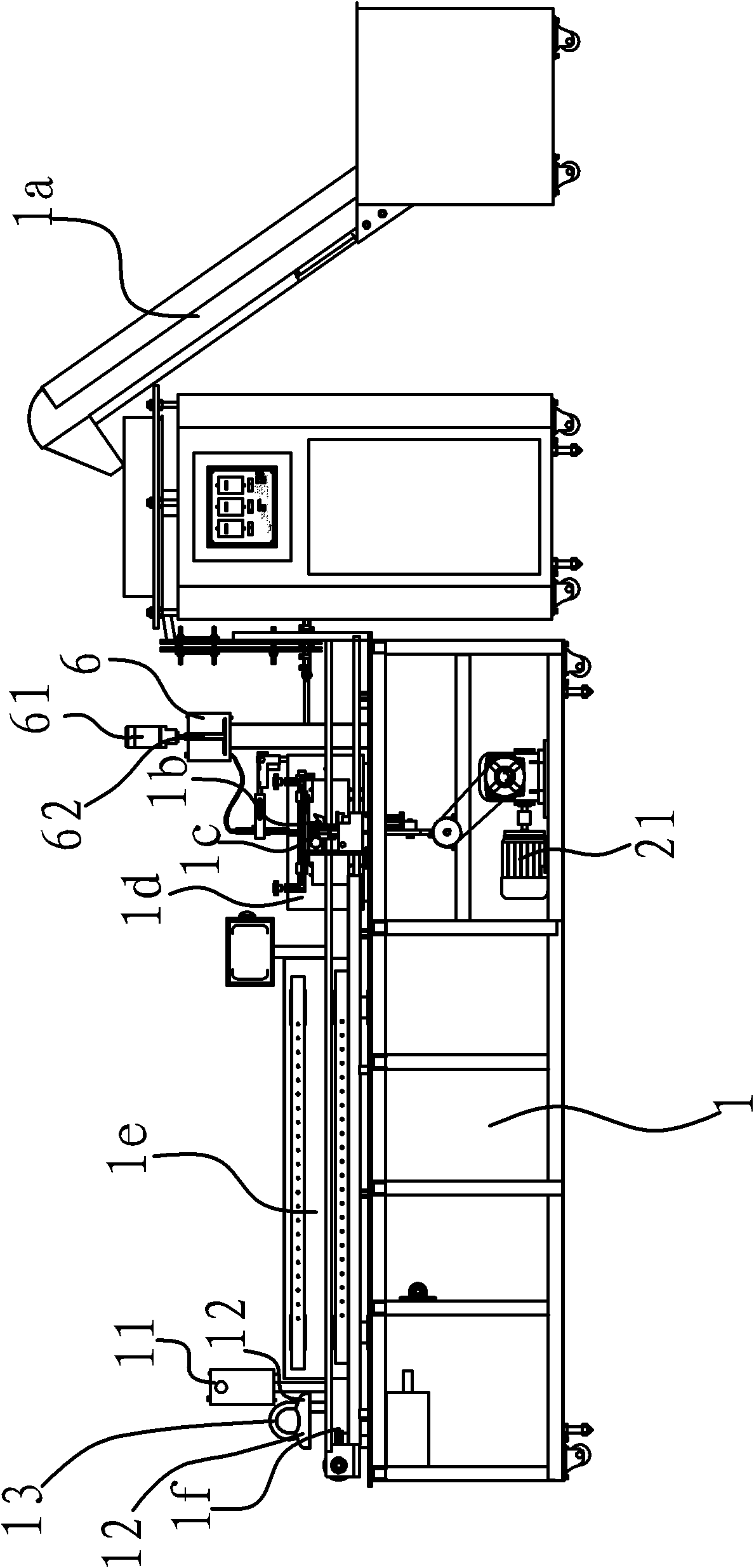

[0033] like figure 1 As shown, the screen printing device is applied to an automatic circular screen printing machine. The automatic circular screen printing machine includes a feeding mechanism 1a, a feeding mechanism 1b, a feeding mechanism 1c, a printing mechanism 1d, a drying device 1e and a discharging device 1f. The invention relates to a material ejecting mechanism 1c and a printing mechanism 1d in an automatic circular screen printing machine, which are used to support workpieces being conveyed and complete printing operations.

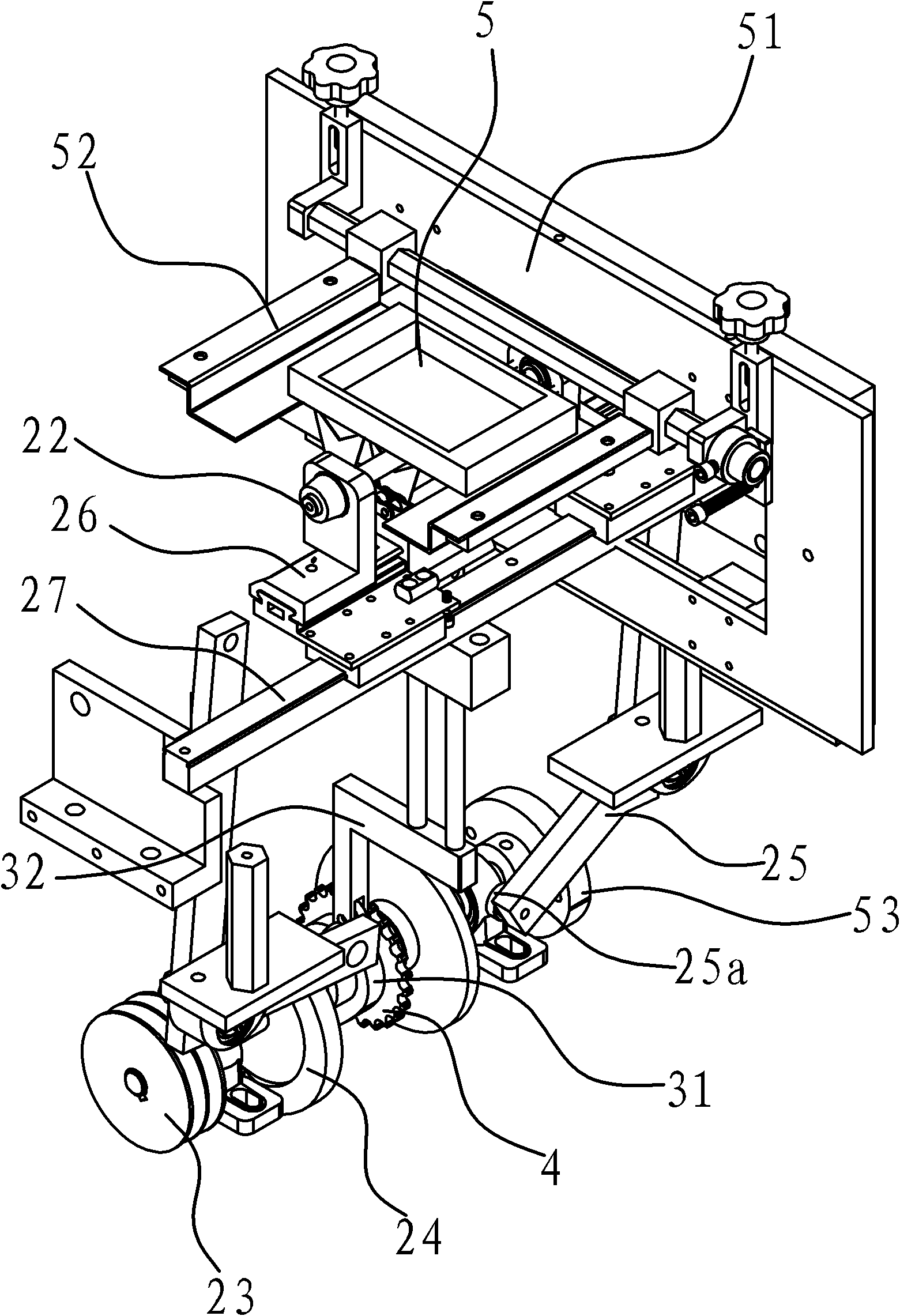

[0034] like figure 2 , image 3 and Figure 4 As shown, the screen printing device is arranged on the frame 1, and includes a conveyor chain 41 for transferring workpieces. There are two conveyor chains 41 and they move synchronously. It is placed between the corresponding brackets 42 on the two conveyor chains 41 under the action of the feeding mechanism 1a. Above the conveyor chain 41 is provided a screen printing ink cartridge 5 for pr...

Embodiment 2

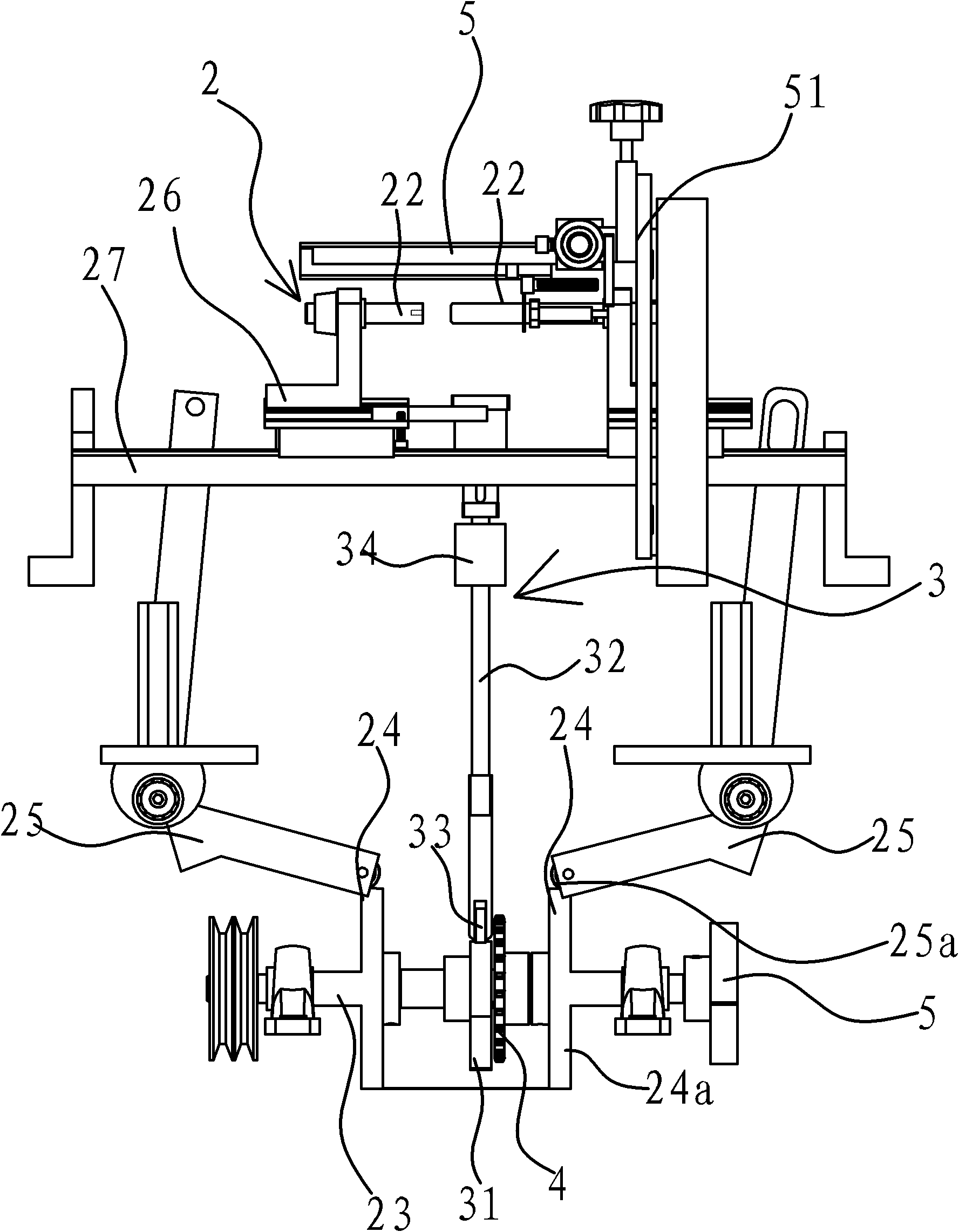

[0044] like Figure 5 As shown, the structural principle of this embodiment is basically the same as that of Embodiment 1, the difference is that the clamping mechanism 2 of this embodiment includes a motor 21, a drive shaft 23 connected to the output shaft of the motor 21, a fixed connection Two side-turning cams 28 on the drive shaft 23 and two rockers 25 hinged on both sides of the frame 1, the outer sides of the two side-turning cams 28 have an active surface 28a with a height difference along their axial direction One end of the rocker 25 is in contact with the action surface 28a of the corresponding side-rotating cam 28 through the roller 25a, and the other end is connected with a fixed seat 26, and the above-mentioned two support members 22 are respectively arranged on the corresponding fixed seat 26. The motor 21 can drive the transmission shaft 23 to rotate through the cooperative relationship such as a pulley, a worm gear, or a bevel gear. When the transmission shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com