Cloth cutting device capable of realizing cutting tidiness

A cutting device and fabric technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of no measuring ruler and inability to accurately measure and cut fabrics, and achieve the effect of conveniently cutting fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

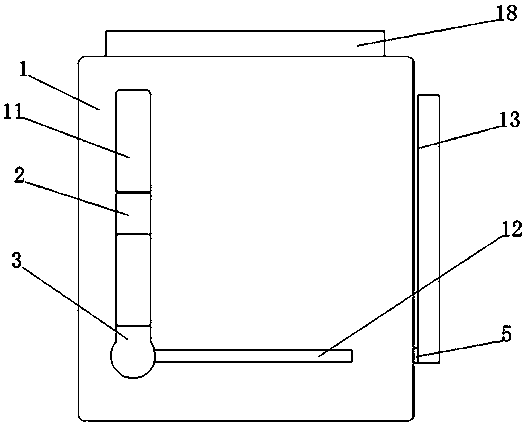

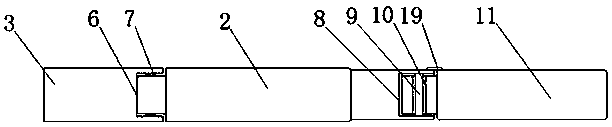

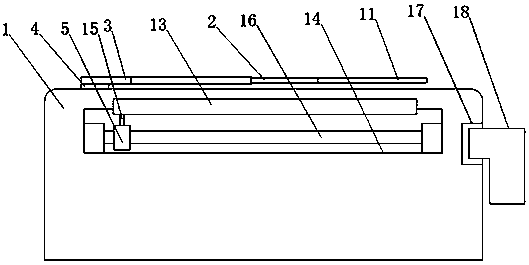

[0028] see Figure 1-3 , a cloth cutting device for cutting neatly, comprising a cutting device body 1, an L-shaped groove 12 is opened on the upper end of the cutting device body 1, and a first slider 4 is slidably connected to the inner end of the L-shaped groove 12, and the upper end of the first slider 4 rotates The connecting plate 3 is connected, and the right end of the connecting plate 3 is provided with a groove 6, and the inner side of the groove 6 is inserted with a telescopic ruler 2, and the left end of the telescopic ruler 2 is matched with the groove 6, and the inner wall of the groove 6 is in contact with the telescopic ruler 2. The surface near one end of the groove 6 is fixedly connected with a semicircular protrusion 7, the right end of the telescopic ruler 2 is provided with a square groove 8, the inner wall of the square groove 8 is fixedly connected with a rotating shaft 9, and the inner side of the square groove 8 is inserted with an angle ruler 11 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com