Plate carrier having a grid pattern for a self-inking stamp and production method

A technology of plate support, grid, applied in the field of plate support including grid for ink return stamp and its manufacture, capable of solving the problems of incorrect centering, waste, poor imprint image, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

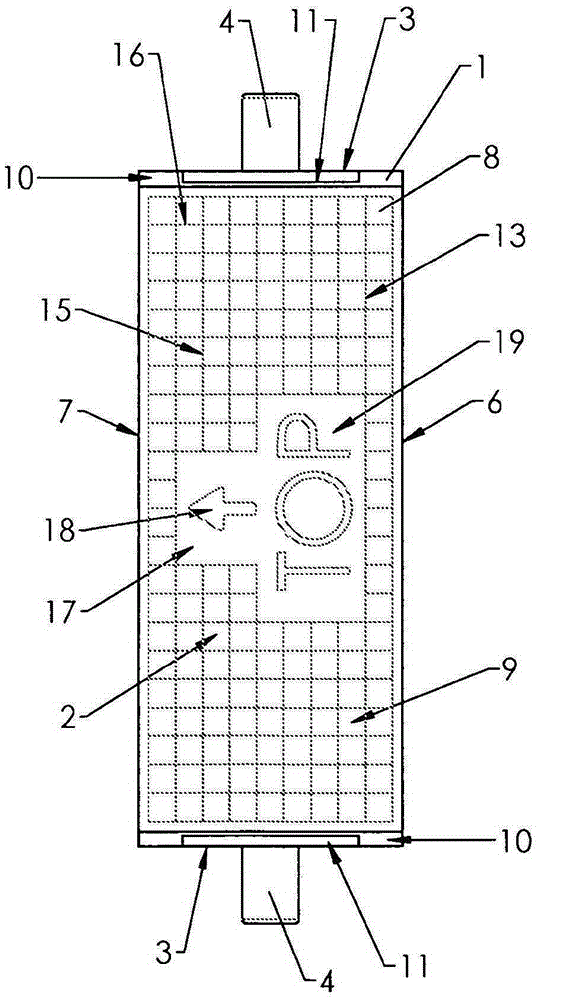

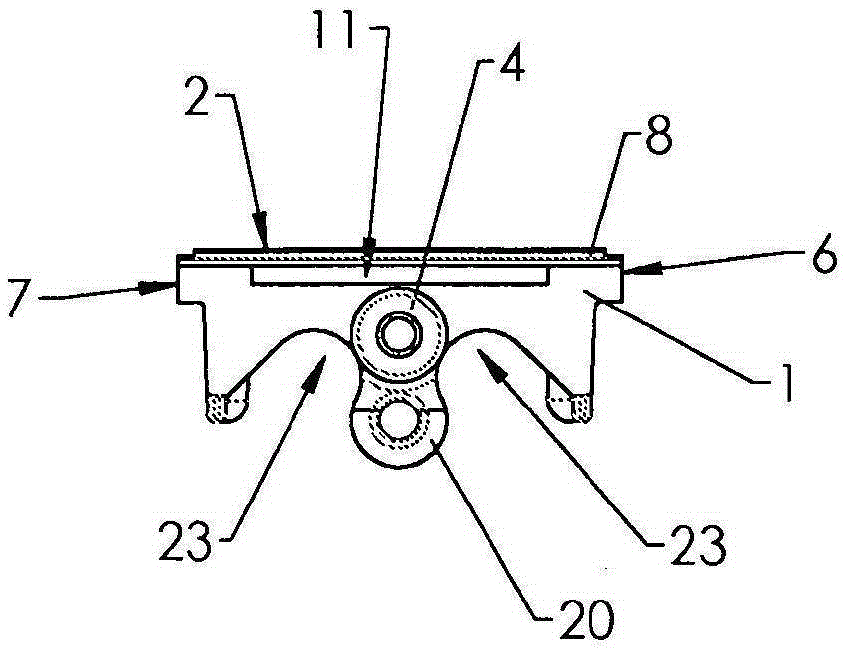

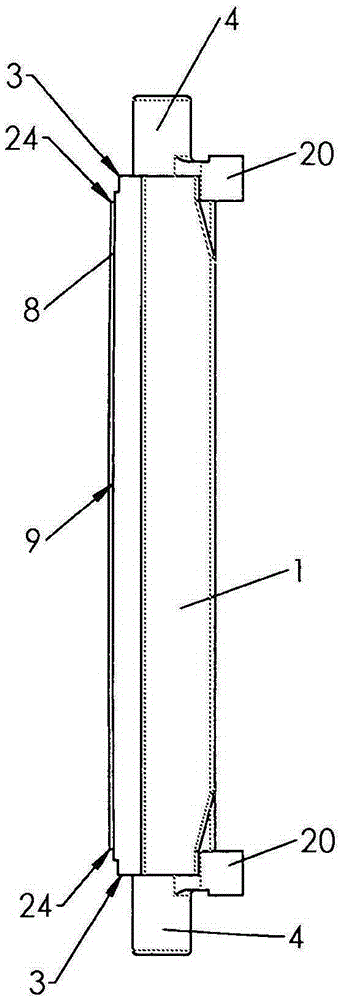

[0023] exist Figure 1A The top view of the board carrier 1 shown in , is directed towards its printed side 2 . Plate support 1 (its arrangement in the ink return stamp is also in more detail below by means of image 3 Explanation) is substantially rectangular, ie the plan view of the printed side 2 is rectangular. From the two lateral (short) edges 3 protruding from the plate support 1 , a pin or shaft part 4 extends in each case. These two shaft parts 4 define the pivot axis of the plate support 1, in the ink return stamp 5 (see image 3 ), the plate support pivots about the pivot axis. Accordingly, the long edges 6 , 7 of the plate carrier 1 are arranged parallel to the pivot axis. On the printed side 2, a double adhesive film 8 (see Figure 1B , 1C ), the double adhesive film constitutes the adhesive surface 9 on the printing side 2 of the board support 1. The double adhesive film 8 covers substantially the entire printed side 2 , but has a slightly smaller longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com