Batch stamping and cutting device for metal plates

A technology of cutting device and metal plate, which is applied in the direction of cutting device with nibbling action, shearing device, accessory device of shearing machine, etc., can solve the problems of people injured and the quality of metal plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

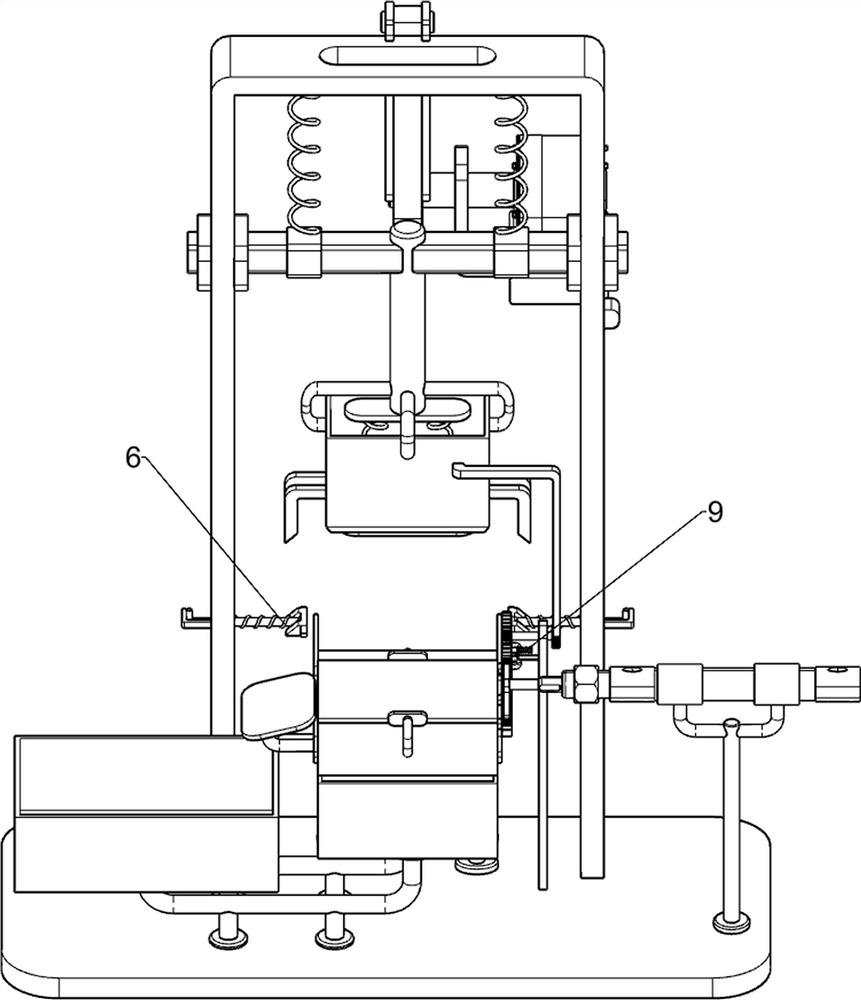

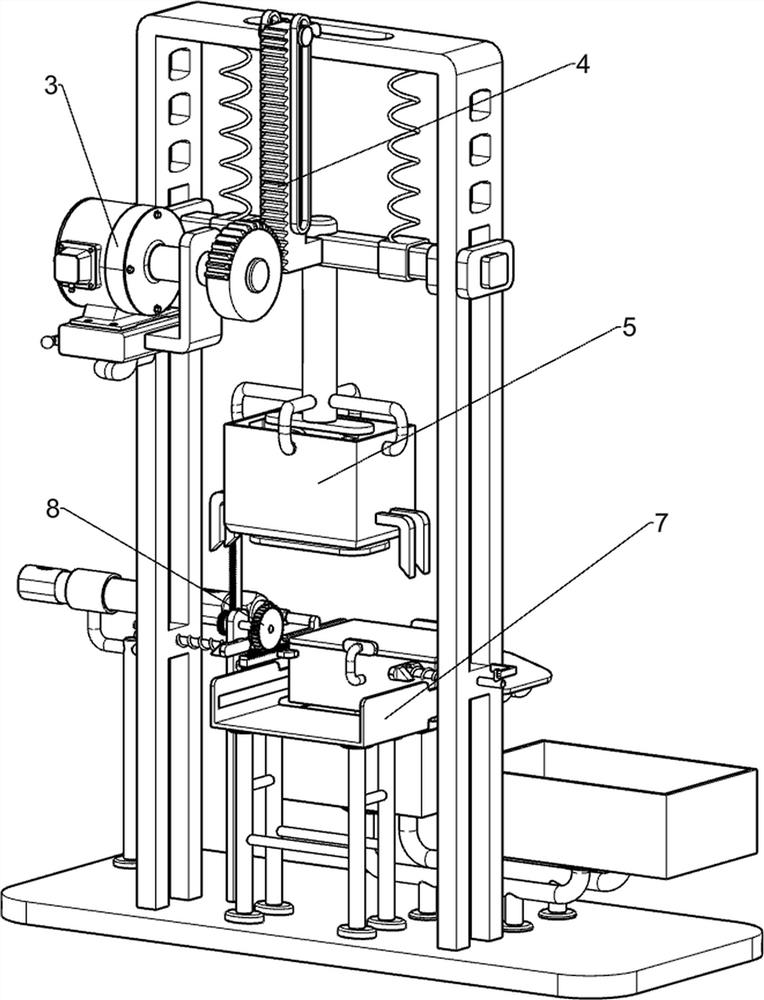

[0032] A batch stamping and cutting device for metal plates, such as Figure 1 to Figure 8 As shown, it includes a bottom plate 1, a mounting frame 2, a driving mechanism 3, a lifting mechanism 4, a punching mechanism 5, a top position mechanism 6, a feeding mechanism 7 and a transmission mechanism 8, and the rear side of the top of the bottom plate 1 is connected with a mounting frame 2 , the rear side of the middle part of the mounting frame 2 is connected with a driving mechanism 3, the rear side of the upper part of the mounting frame 2 is connected with a lifting mechanism 4, and the lifting mechanism 4 is connected with a punching mechanism 5, between the lower part of the mounting frame 2 and the punching mechanism 5 A jacking mechanism 6 is connected, a discharge mechanism 7 is connected to the rear side of the middle part of the bottom plate 1 , and a transmission mechanism 8 is connected between the right side of the top of the bottom plate 1 and the discharge mechani...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 10 As shown, a discharge mechanism 10 is also included, and the discharge mechanism 10 includes a second fixed mount 101, a cylinder 102 and a second top block 103, and the front side of the bottom plate 1 top is connected with a second fixed mount 101, and the second fixed mount A cylinder 102 is connected to the top of the cylinder 101, and a second jacking block 103 is connected to the telescopic rod of the cylinder 102.

[0042] Also includes material receiving mechanism 11, and material receiving mechanism 11 includes inclined sliding frame 1101, the third fixed mount 1102, waste material receiving box 1103 and material receiving box 1104, the left side of discharging frame 73 is connected with inclined sliding frame 1101, bottom plate 1 The front side of the top is connected with a third fixed frame 1102, the third fixed frame 1102 is located at the rear side of the second fixed frame 101, the front side of the third fixe...

Embodiment 3

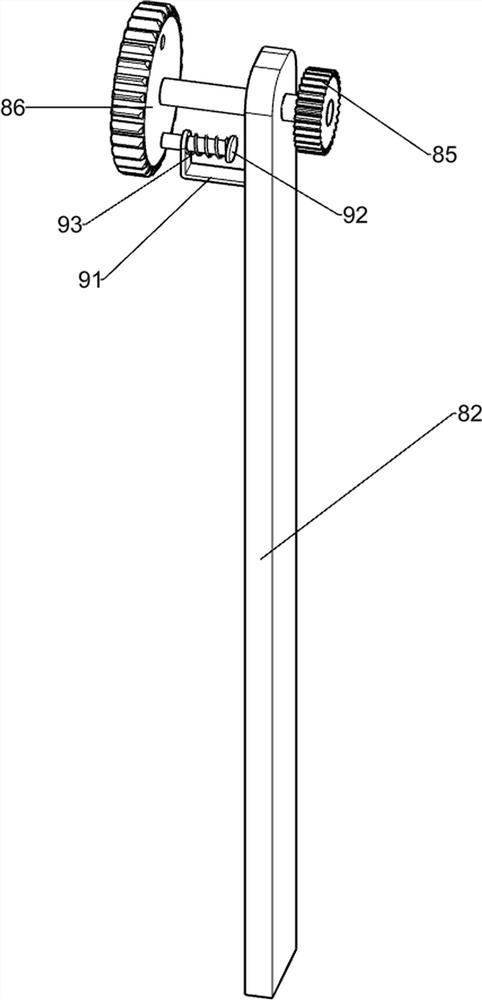

[0045] On the basis of Example 2, such as Figure 9 As shown, it also includes a locking mechanism 9. The locking mechanism 9 includes a fixed block 91, a guide post 92 and a tension spring 93. The left side of the upper part of the positioning plate 82 is connected with a fixed block 91, and the fixed block 91 is slidably connected. A guide post 92 is arranged, and the guide post 92 is matched with the groove, and a tension spring 93 is connected between the fixed block 91 and the guide post 92 .

[0046] Under the cooperation of the guide post 92 and the groove, when the cutter 52 cuts the metal plate, the transmission spur gear 86 and the third rack frame 84 maintain a certain stability, thereby indirectly making the discharge frame 73 and the metal plate The plate is more stable, which further improves the precision of cutting the metal plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com