Cutting nippers

A technology of cutting pliers and pliers, which is applied in the field of cutting pliers with precise cutting and fastening functions. It can solve the problems of lower production efficiency, deformation of pipes, wire harnesses or sheet objects, and excessive dimensional errors, so as to improve production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

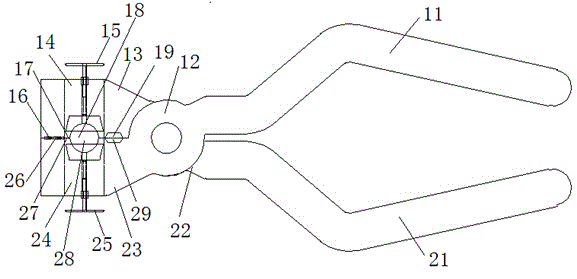

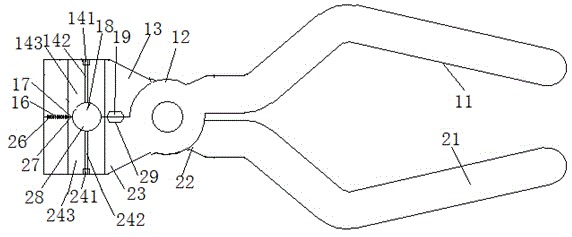

[0023] Such as Figure 1-Figure 8 The shown pair of scissors includes a first pliers body and a second pliers body that are pivotally connected.

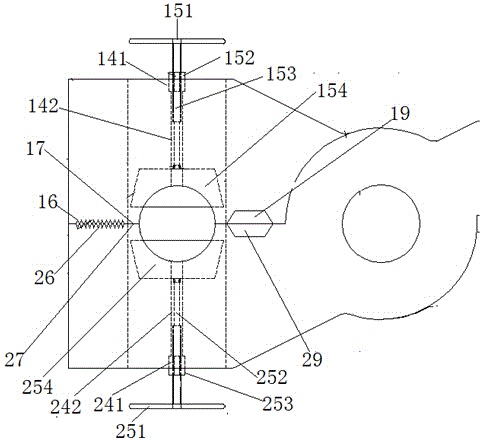

[0024] The first pliers body includes a first jaw section 13 , a first pivot section 12 and a first pliers handle section 11 which are sequentially connected. The middle of the inside of the first jaw section 13 is provided with a first open slot 14 for installing a shearing device (there are two "middle" shaped slots for installing a rotating table), and the first open slot 14 is provided with a first shear Cutting device 15. The inner wall of the first jaw section 13 is sequentially provided with a first anti-slip tooth 16, a first platform 17 (for cutting sheet objects), a first semi-cylindrical through hole 18 and a first shearing tooth from front to back. Mouth 19. Such as Figure 4 As shown, the first shearing device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com