Table-type cloth cutting machine with sliding guide rail

A cutting machine and guide rail technology, applied in the field of cutting machines, can solve the problem of inaccurate cutting and achieve the effect of solving the effect of inaccurate cutting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

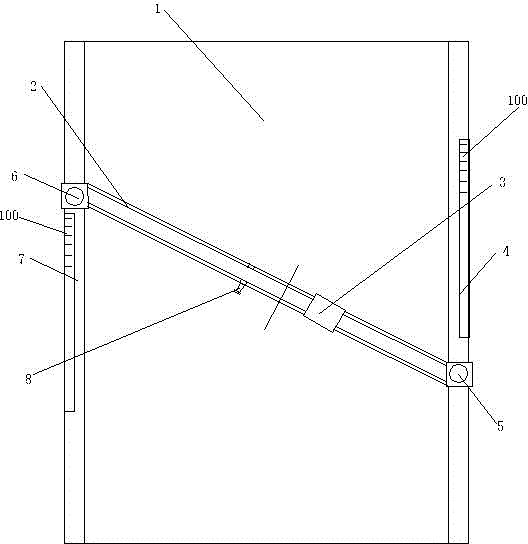

[0015] Embodiment 1: see figure 1 , Figure 7 Shown: a cutting machine, including a bed 1, a guide rail 2, a first slide 7 and a second slide 4 on both sides of the bed 1, between the first slide 7 and the second slide 4 there is a The guide rail 2 that moves on the first slideway 7 and the second slideway 4. The guide rail 2 includes a first guide rail 31 and a second guide rail 32, which can slide relatively between the first guide rail 31 and the second guide rail 32, and the length of the entire guide rail 2 can be adjusted. and on the second slideway 4, so the guide rail 2 can present a certain angle on the two slideways. There is a first fixing part 8 on the first guide rail 31 , and the first fixing part 8 can fix the first guide rail 3 on the second guide rail 32 . The first fixing member 8 can be a simple screw fixing or other fixings. The length of the guide rail 2 can be determined after the first fixing member 8 is fixed. The second fixing member 6 fixes the f...

Embodiment 2

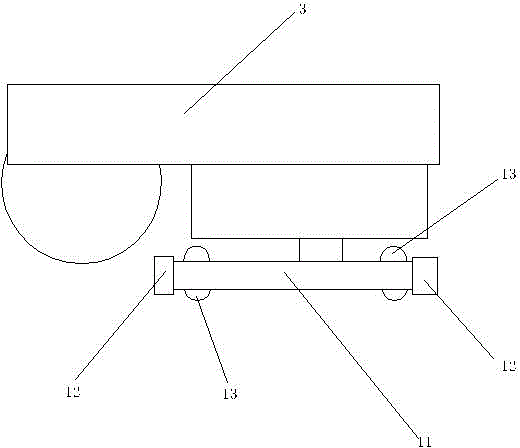

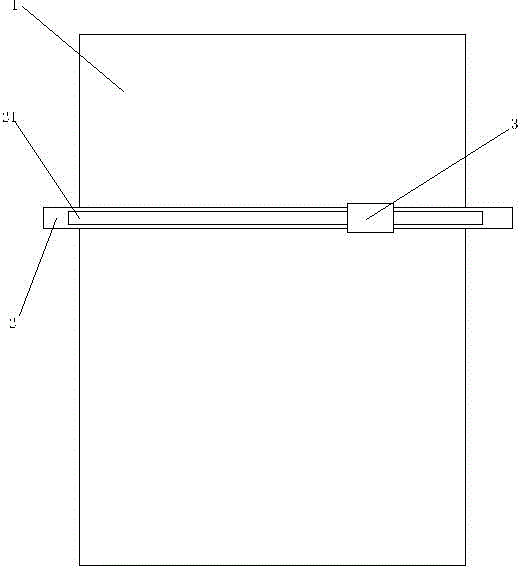

[0017] Example 2: see image 3 , Figure 4 , Figure 5 Shown: a cutting machine, including a guide rail 2, a cutter 3 that can move on the guide rail 2, a first conveying device 21 is arranged inside the guide rail 2, and a second conveying device 21 that matches the first conveying device 21 is arranged on the cutter 3 Conveyor 24. Rely on the first conveying device 21 on the guide rail to drive the second conveying device 24 on the cutter 3 like this, allow the cutter to move. The first transmission device 21 is a first worm 22 and a second worm 28 , and the second transmission device 24 is a first gear 41 cooperating with the first worm 22 and the second worm 28 . The first worm screw 22 and the second worm screw 28 are on both sides in the track 2, and the first gear 41 on the cutter fits with the first worm screw 22 and the second worm screw 28 respectively, and starts the first worm screw 22 and the second worm screw 28 simultaneously, The first gear 41 on the cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com